Quality assurance of resins

during blending and conditioning

during blending and conditioning

In the dynamic world of resin and binder production,

constant quality assurance is a must – for efficient production and stable processes.

±0.05 wt% Accuracy

Real-time measurement

Maintenance-free

Profitable

Challenges in blending and conditioning of resins

Precise monitoring of the final concentration in the dilution process of resins (or binders) can prevent costly rework of the batch. Classical laboratory control methods are often inadequate - they are time-consuming and results are only available with delay. Thus, these methods do not allow continuous monitoring. Errors quickly lead to quality fluctuations or rejects.

Challenges

-

Ensure homogeneous mixture without air inclusions or gas bubbles

-

Consider mixing behavior when diluting the resin

-

Observe temperature and humidity conditions

-

Avoid uneven final concentrations

Solution: LiquiSonic®

-

Clear monitoring with LiquiSonic®

-

Immediate display of concentration

-

Seamless integration into existing systems

-

Maintenance-free and without consumables

-

Gas bubble detection and compensation

-

Reliable measurement in the temperature range from -40 °C to 200 °C

Your advantages

-

Traceable and reliable measurement results

-

Measurement results in real-time

-

Reduction of dosing time

-

Completely maintenance-free sensors and chemically resistant materials

-

Easy integration into systems of any size and configuration

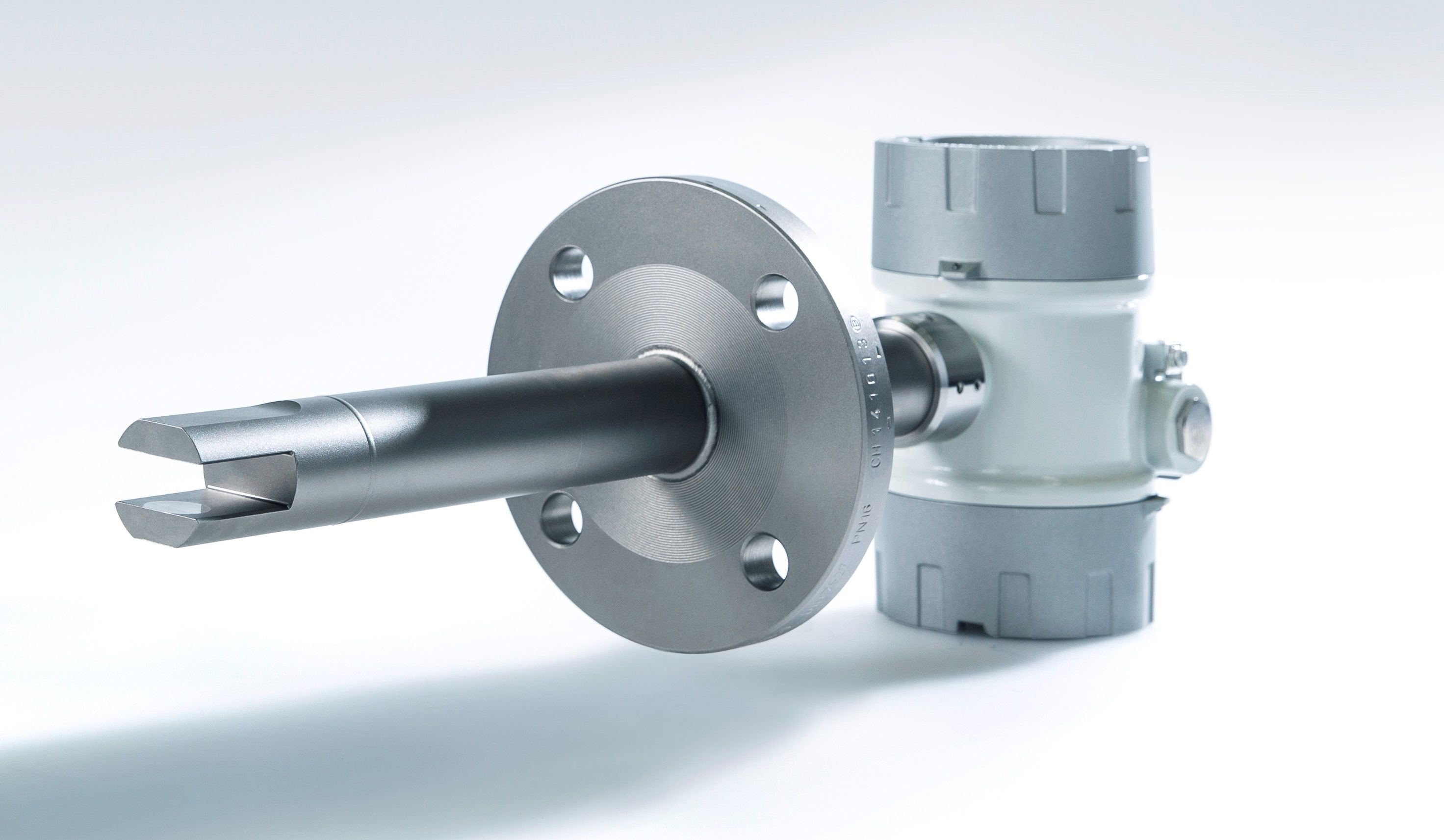

Our solution: The LiquiSonic® Measurement system

Monitor concentration in real-time

LiquiSonic® combines modern ultrasonic technology with temperature-compensated measurement to deliver precise results in blending and conditioning of resins. Real-time monitoring ensures stable product quality, for example, by early detection of deviations in the final concentration and provides data for process optimization. This reduces operating costs and material consumption while increasing process safety and efficiency. LiquiSonic® offers an alternative to viscosity measurement and also enables reliable detection of gas bubbles.

-

Quality can be ensured in every batch, incorrect dosages are corrected immediately

-

The efficiency of a process plant can be increased through automated regulation and the elimination of laboratory measurements

-

Optimization of process steps through detection of gas bubbles and air pockets

Technical and economic details

Ultrasonic measuring principle

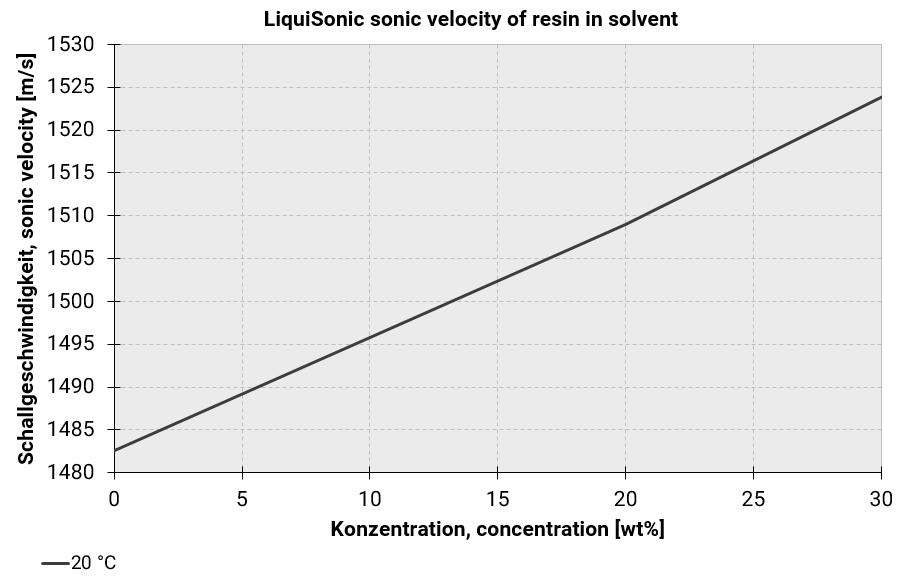

The ultrasonic measuring method of LiquiSonic® based on a highly precise time measurement. From the measured sound travel time and the known distance between the transmitter and receiver, the speed of sound is calculated, which is directly related to the resin concentration. This allows the concentration to be determined continuously and in real-time during blending and conditioning. Compared to conductivity meters, which do not work with non-conductive resins, or density meters, which provide inaccurate results with highly viscous media, ourultrasonic measuring device LiquiSonic® robust and process-secure. Viscosity measurements also initially deliver good results, but overall they are slower, less sensitive to small concentration fluctuations, drift over time, and often clog. LiquiSonic® Sensors are temperature-compensated and offer high long-term stability, allowing them to provide reliable measurements even in variable process environments. Additionally, the sensor length or installation variant can be precisely adapted to the plant geometry, enabling optimal positioning in the process. Continuous measurement also allows for reliable detection of gas bubbles that could falsify the measurement result.

Economic benefit

Economic benefit

In addition to the technical advantages, the use of LiquiSonic® also offers significant economic potential that can directly lead to cost reductions and higher process efficiency:

-

Reduction of scrap and rework through immediate detection of mis-mixes

-

Less raw material consumption thanks to precise dosing and optimized final concentrations

-

Minimization of downtimes, as no time-consuming laboratory analyses are necessary

-

Faster reaction times in case of process deviations through continuous real-time measurement

-

Lower energy consumption, as correction and treatment processes become unnecessary

-

Longer plant availability through robust, maintenance-free sensors

-

Quick ROI through reduced operating costs, higher process stability, and manageable acquisition costs

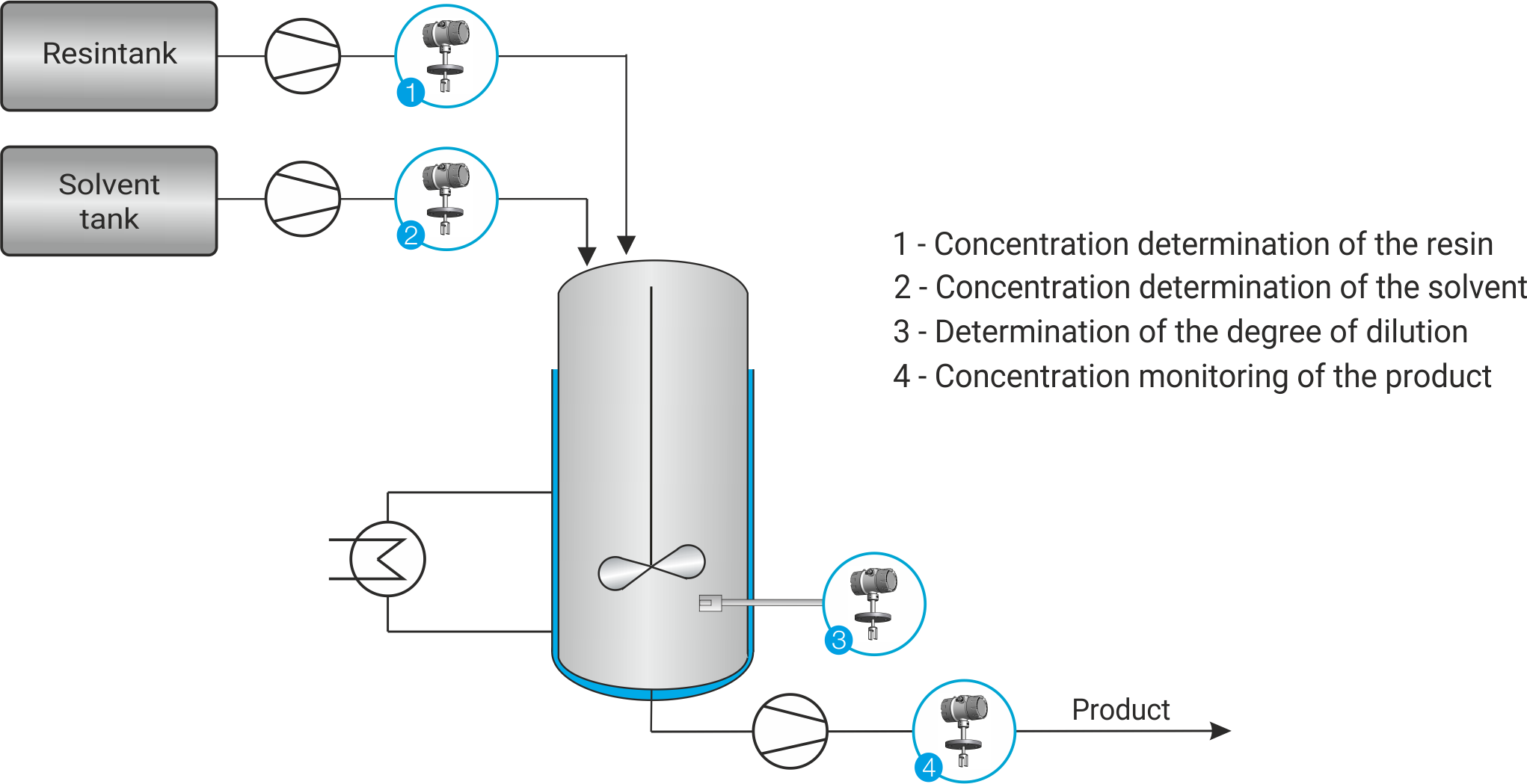

Application example

Application example

When diluting polymer resins, precise adjustment of the final concentration is crucial for consistently high product quality. The LiquiSonic® Measurement system überwacht die Konzentration kontinuierlich per Ultraschallmessung und erkennt selbst kleinste Abweichungen in Echtzeit. Dadurch lassen sich Fehlmischungen vermeiden und der Materialeinsatz exakt steuern. Die robuste Plug-&-Play-Sensorkonstruktion ermöglicht eine direkte Integration in den Prozess. Zusätzlich erfasst das System den Gas- bzw. Luftanteil im Rührvorgang, sodass der optimale Zeitpunkt für nachfolgende Prozessschritte bestimmt werden kann. Alle Messwerte werden automatisch dokumentiert und stehen für nachträgliche Analysen zur Verfügung.

Success stories and references:

You can receive detailed case studies and customer references from our sales team. Feel free to contact us for specific application examples!

The main advantages at a glance

Consistent quality

Real-time monitoring prevents deviations and ensures consistent product quality.

Cost savings

Reduced chemical consumption and lower operating costs through optimized processes.

Highest efficiency

Real-time data enables faster decisions and optimized processes.

Maintenance-free

Sensors are chemical-resistant and require no consumables.

Frequently asked questions

SensoTech GmbH is a leading company in the field of process measurement technology based in Barleben, near Magdeburg, Germany. We develop and produce innovative solutions for monitoring and optimizing industrial processes. Our specialization lies in the precise measurement of concentrations, densities, and other parameters in liquids - in real-time and directly during the process.

Im Vergleich zu Leitfähigkeitsmessgeräten, die bei nicht leitfähigen Harzen nicht funktionieren, oder Dichtemessgeräten, die bei hochviskosen Medien ungenaue Ergebnisse liefern, ist unser Ultraschallmessgerät LiquiSonic® robust and process-secure. Viscosity measurements also initially deliver good results, but overall they are slower, less sensitive to small concentration fluctuations, drift over time, and often clog. LiquiSonic® Sensoren sind temperature compensated and offer a high long-term stability, so that they provide reliable measurements even in variable process environments. The LiquiSonic® measuring technology also contains no moving parts or components that can wear out or be consumed. Therefore, after installation, the measuring system is completely maintenance-free and drift-free. The sensors offer digital signal transmission up to 1000 m and enable continuous inline measurement without sample extraction.

The system is completely maintenance-free. There are no mechanical wear parts, seals, or optical windows that could be compromised. Regular calibration is not required - no drifting or sticking - our sensors remain stable for years.

Unser System nutzt die Ultraschall-Laufzeitmessung zur Bestimmung der Schallgeschwindigkeit in der Endkonzentration von Harzen oder Bindemitteln. Diese Schallgeschwindigkeit korreliert direkt mit der chemischen Konzentration and ermöglicht measurement accuracies of ±0.05 wt%. The integrated temperature compensation ensures stable results even with fluctuating process conditions.

The system delivers results in real-time. Based on the measurements, you receive a current reading every second. This fast response time enables effective process control when blending and conditioning resins and early detection of deviations or gas bubbles.

Yes, by combining sound velocity measurement with additional physical quantities (e.g., conductivity), multiple components can be determined simultaneously. This allows monitoring of additional additives alongside the final concentration of the resin.

The system offers various digital interfaces (e.g., Profibus, Ethernet/IP, Foundation Fieldbus) as well as analog 4-20 mA outputs. The Integration proceeds smoothly via standardized protocols.

Since the speed of sound is influenced by temperature, all our LiquiSonic® sensors are equipped with high-precision temperature sensors. This allows the influence of temperature on the measurement to be directly compensated to be directly compensated. Therefore, it is not necessary to integrate additional temperature sensors.

Our sensors operate reliably within a temperature range from -40 °C to 200 °C and pressures up to 500 bar. Through various material options such as stainless steel, Hastelloy, or PFA coatings, aggressive media can also be measured. Ex protection for Zone 1 and 2 is also available.

Yes, our sensors are also designed for extreme conditions. In addition to the extended temperature and pressure range, we offer customizations such as sensor lengths up to 3000 mm, special alloys for corrosive media, and various protection types, such as optional explosion protection. Each sensor is customized according to your requirements configured.

Further applications

Polycondensation

Polycondensation represents the central step in the production of polymer resin and is particularly susceptible to fluctuations in the process. Even slight deviations in the reaction progress can lead to an excessively high degree of cross-linking.

Formaldehyde production

Formaldehyde production places high demands on process management, as even small deviations in methanol oxidation have noticeable effects on efficiency, product quality, and plant condition.

Pickling bath monitoring

Pickling baths remove oxides or impurities from metal surfaces and must be consistently maintained within the correct concentration range.

H₂SO₄ measurement

In copper extraction, sulfuric acid is used to dissolve copper from the ore, making precise monitoring of the acid concentration crucial for an efficient leaching process.

AdBlue® production

AdBlue® is an aqueous urea solution whose precise concentration and purity are of central importance for compliance with emission standards in SCR systems.

Chlor-alkali electrolysis

In chlor-alkali electrolysis, concentrated salt solutions are electrolytically decomposed into chlorine, caustic soda, and hydrogen, with a constant brine concentration ensuring process stability.