Carbon Capture

Sensors for process optimization of CO2 scrubbers

MDEA, DEA, K2CO3, NaOH

high resistance

Maintenance-free & cost-saving

Measurement accuracy ± 0.05 %

Efficiency maximization through optimal amine concentration

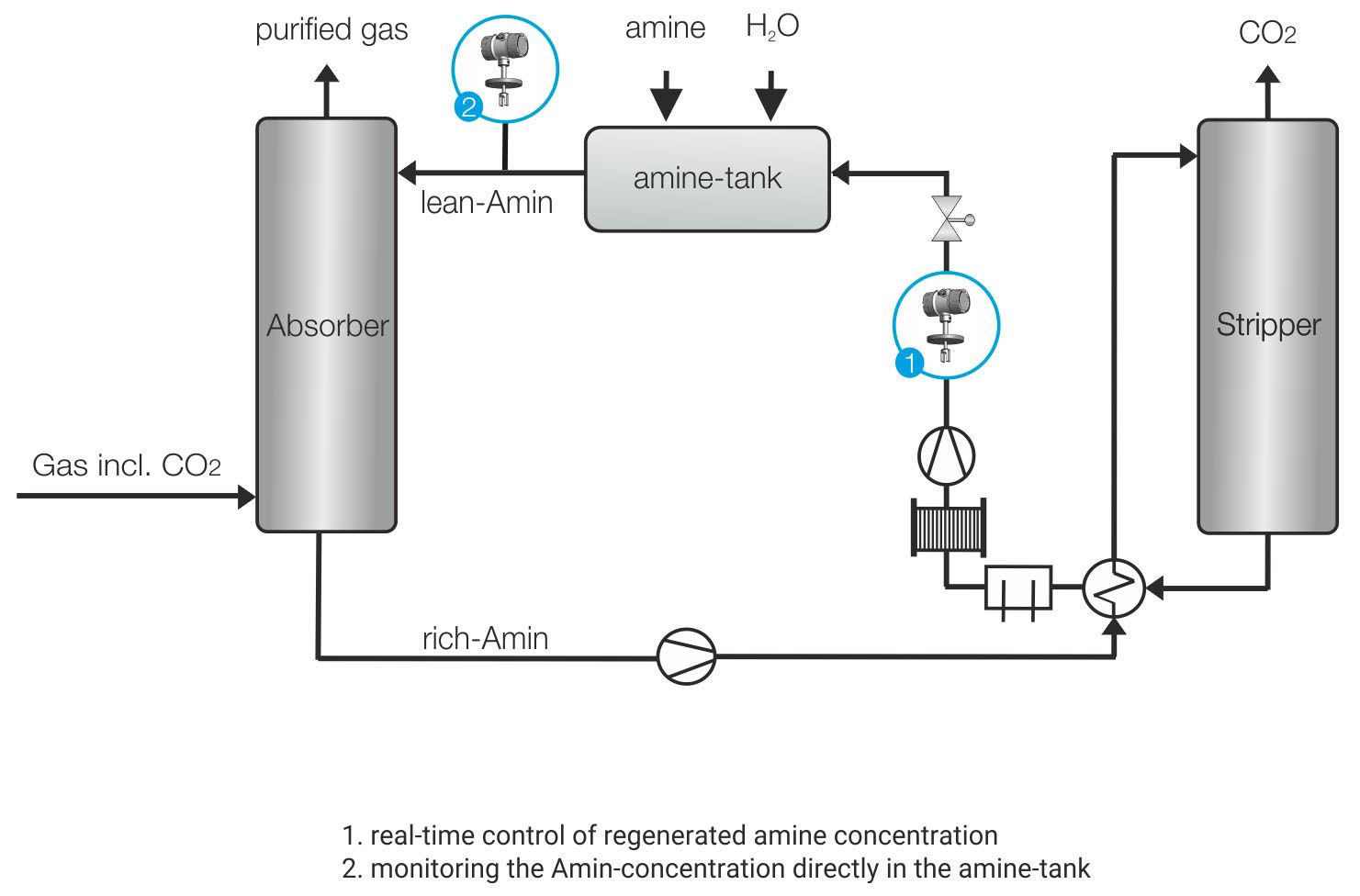

The capture of carbon dioxide plays a crucial role in combating climate change and reducing greenhouse gas emissions. Scrubbers are of decisive importance in the process of CO2-Absorption. A key component in a scrubber is the scrubbing fluid, monitoring of which is critical. By constantly measuring the washing liquid, the performance of CO2-absorption can be kept in the ideal range.

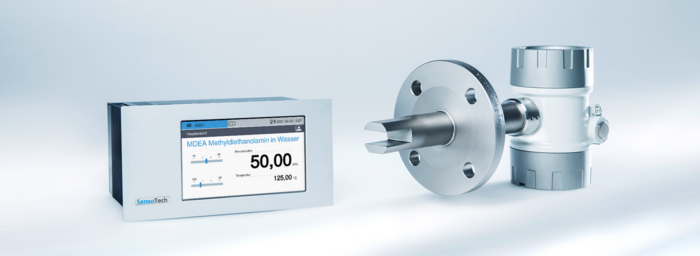

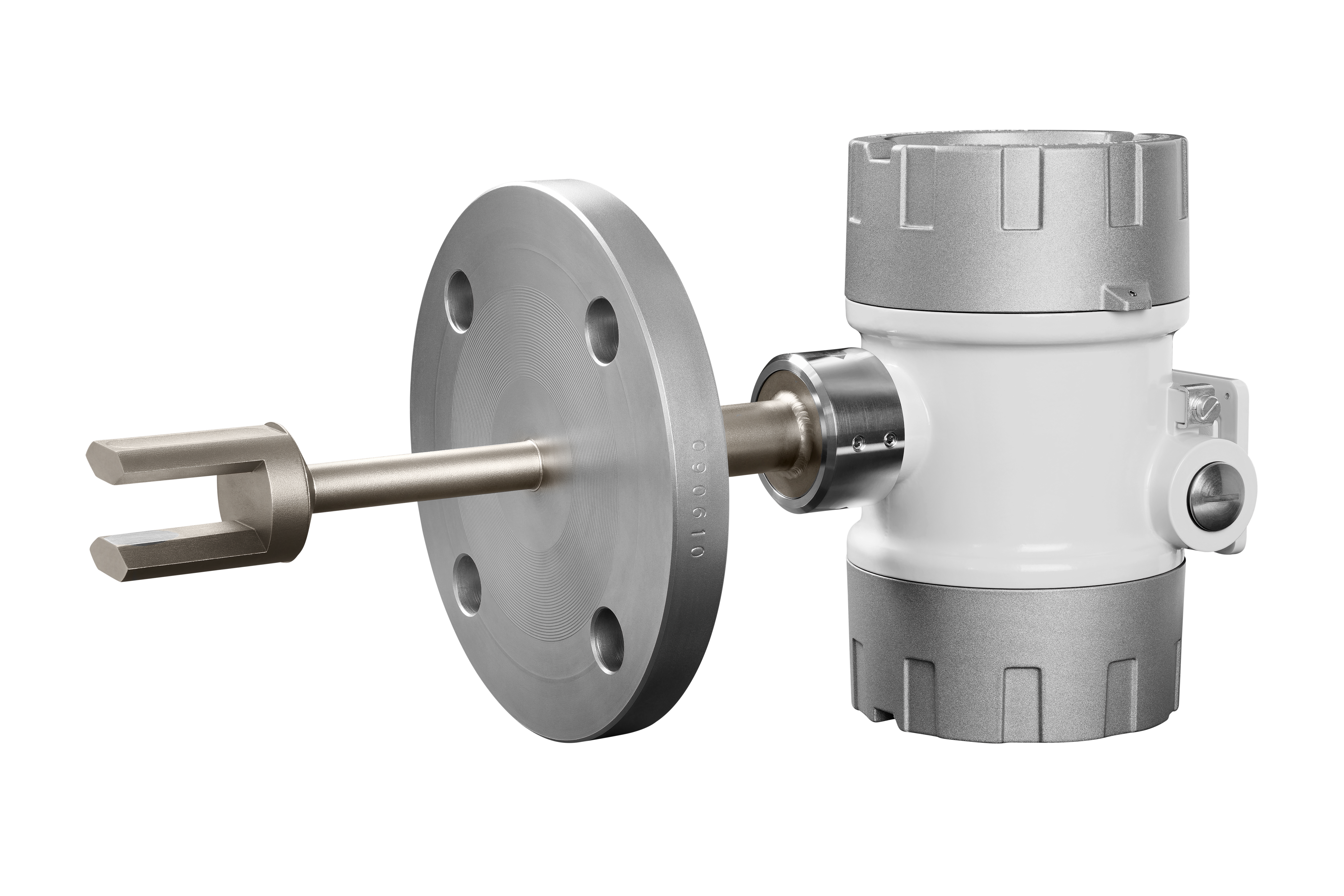

This optimizes the use of process fluids and minimizes operating costs. In this way, we combine ecological responsibility with economic efficiency. LiquiSonic® provides precise analysis and monitoring of the washing liquid through ultrasonic measurements with an accuracy of up to ± 0.05 %.

The robust plug & play sensor design ensures a long system lifespan and reduces time-consuming laboratory measurements. Furthermore, the measurement system extends the lifespan of your process plant by reducing corrosion, which can occur due to overdosing.

Cost reduction through process optimization

For the effective operation of a carbon capture system, precise determination of the amine concentration is essential. An over-concentration can lead to unnecessary regeneration of incompletely loaded amine, driving up energy costs. On the other hand, too low an amine concentration can result in the CO2 not being completely removed from the system. As a result, the CO2 cannot be completely stored and is released into the environment.

To overcome these challenges, the LiquiSonic® measurement system is already widely used. It can continuously determine the concentration of the absorption liquid with an accuracy of up to ± 0.05 %. Through the application of LiquiSonic® ensures efficient separation of CO2 ensures, which additionally helps to minimize costs for energy, chemicals, and laboratory work. The LiquiSonic® measurement system thus plays an essential role by ensuring and optimizing the efficiency and sustainability of the carbon capture process.

contact process

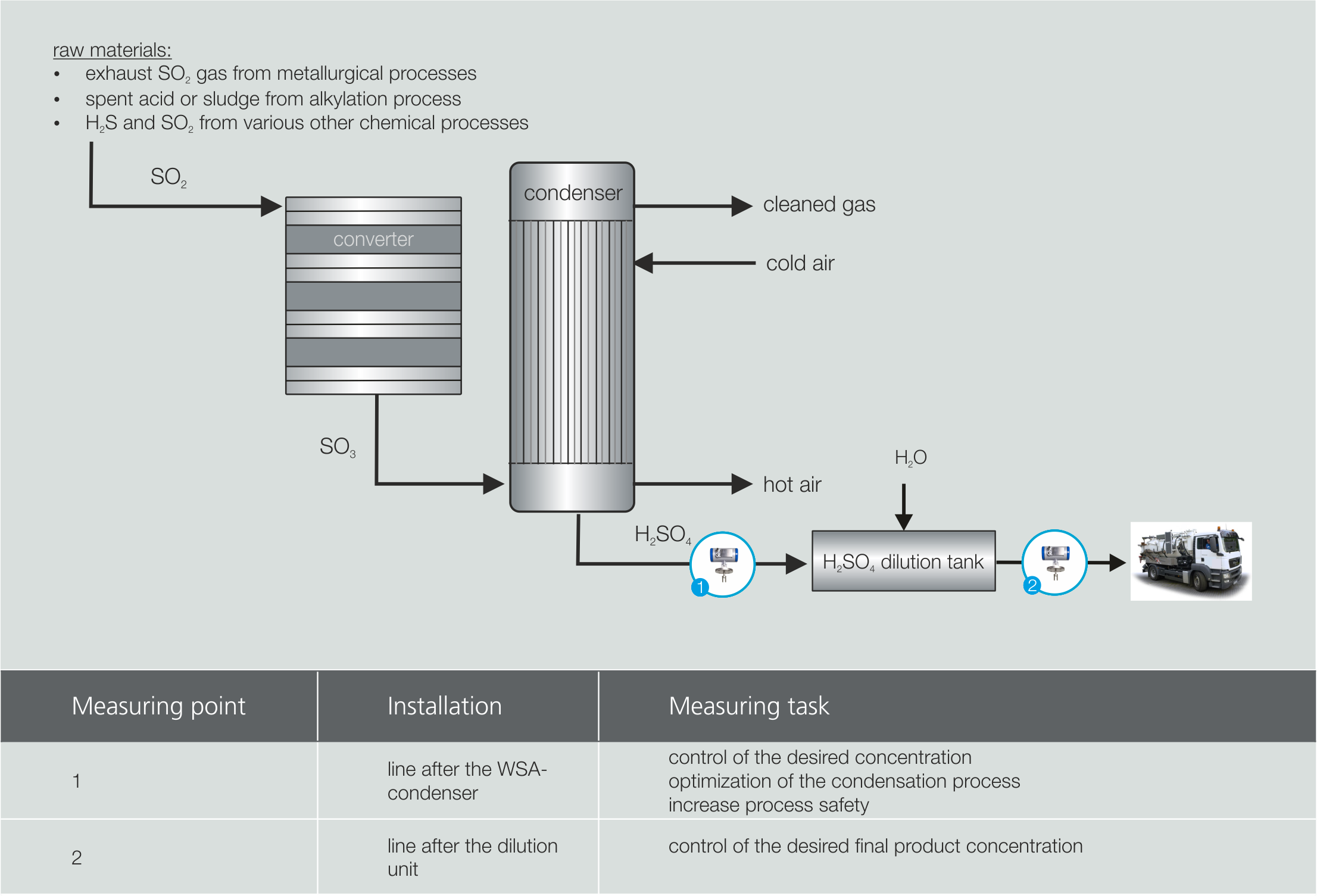

The contact process (WSA) was originally developed to remove sulfur components from flue gases of various industrial manufacturing processes. Unlike the double contact process, the water vapor remains in the resulting SO2. Thanks to a special vanadium-containing catalyst, the gas has no negative effects on the catalytic oxidation of SO2 to SO3 in the converter.

Finally, in the contact process, sulfur trioxide enters the condenser, where water vapor condenses and SO3 into H2SO4 is converted. A concentration of 98 wt% is typical here. To measure the concentration directly in the line, installation of the LiquiSonic®sensors at the end of the condenser and the dilution unit is required.

Energy cost savings

> 40,000 €/year

Labor cost savings

> 20,000 €/year

Increase in plant safety

Increase in process performance

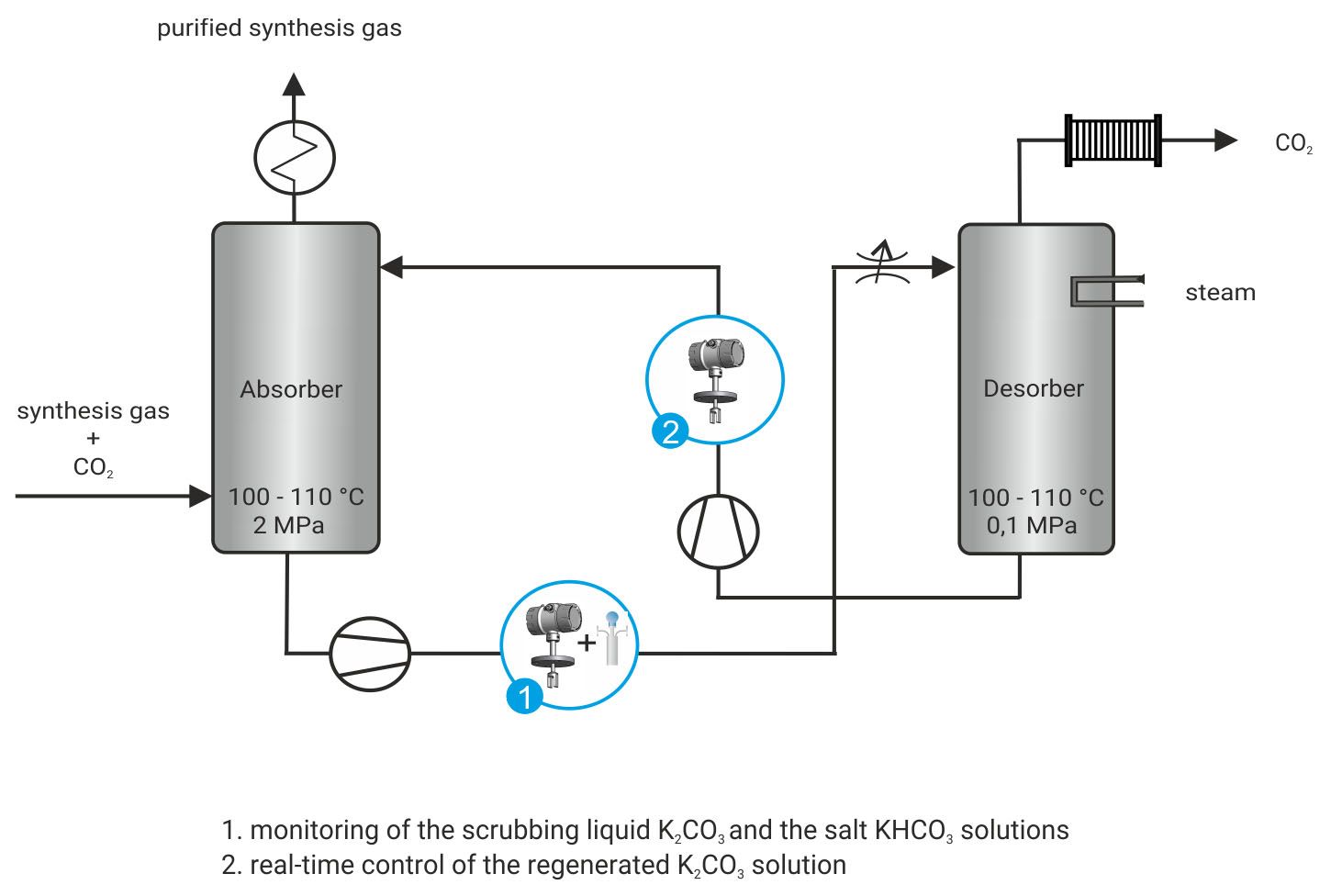

Process optimization through combination measurements

In the consideration of multi-component systems, such as in the context of Benfield process gas scrubbers, the precise determination of the concentration of the washing solution and the salt content is an essential aspect for efficient and cost-optimized process management in the removal of CO2.

In this regard, the LiquiSonic® measurement system offers a precise and continuous solution. It allows accurate monitoring of the mentioned process parameters, enabling a significant reduction in material and energy costs while minimizing laboratory costs. Precise real-time monitoring also increases process safety, thereby reducing the risk of production downtime.

Furthermore, the LiquiSonic® measurement system impresses with its robustness and durability. Even under demanding operating conditions, it reliably provides precise measurements and is capable of capturing and documenting process fluctuations in real time.

MDEA natural gas scrubber

LiquiSonic® Systems are used by globally known companies like BASF for the process of amine scrubbing to separate CO2 used. To learn more, click the button

We solve your measurement task

Feel free to contact us.

We support you in solving your individual measurement task.