The LiquiSonic®-measuring systems enable efficient inline monitoring of numerous processes.

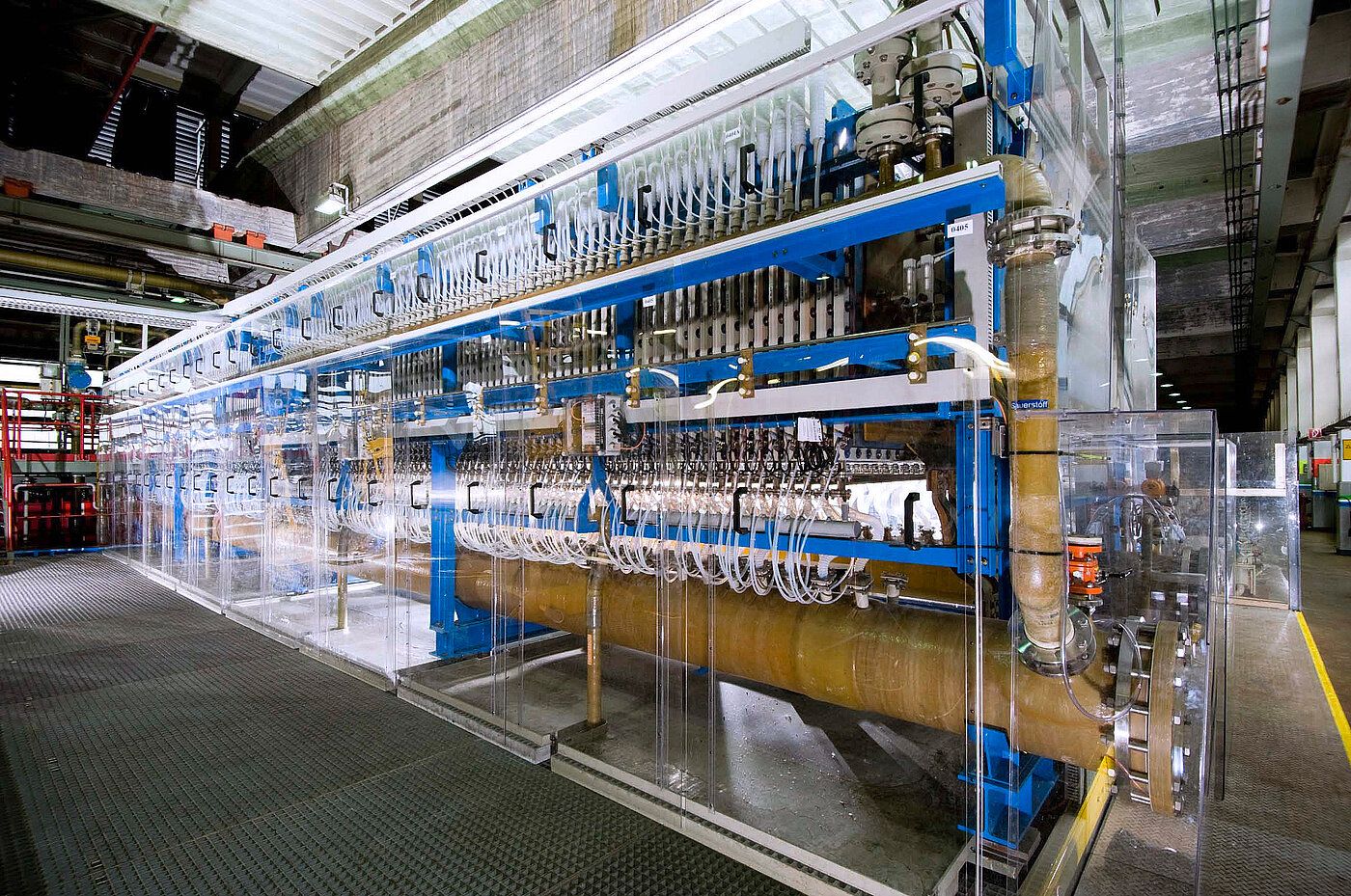

In chlor-alkali electrolysis, LiquiSonic® ensures that the feedstocks are in perfect condition. The online measuring system also supports the monitoring of electrolysis products for further processing.

In our webinar, you will learn how LiquiSonic® Helps you extend the life of your membranes and avoid quality failures in brine cleaning. We also show how LiquiSonic® Saves energy costs by ensuring a maximum NaCl concentration.

The webinar is aimed at operators in the chlor-alkali production process.

The LiquiSonic® Measuring system is directly integrated into the system. It is plug & play and can be used for measurements immediately after installation. The sound velocity measurement method allows for a very robust sensor design. LiquiSonic® is thus maintenance-free and has a very long service life - often over 10 years. SensoTech provides the complete solution for the automation and optimization of processes around chlor-alkali electrolysis.

Is participation on the specified dates not possible? Contact us for an individual presentation - also by email at