Optimize your formaldehyde production

with LiquiSonic®

with LiquiSonic®

Formaldehyde production is an energy-intensive process where small deviations can have a large impact on quality, costs, and plant availability. With LiquiSonic®, you monitor chemical concentrations inline and in real-time.

Challenges in formaldehyde production

Formaldehyde production places high demands on process management, as even small deviations in methanol oxidation can have noticeable effects on efficiency, product quality, and plant condition. Continuous transparency about the actual composition of the liquid product stream is often lacking, so changes can only be detected with a time delay. Fluctuating residual contents indicate declining catalyst activity, while an incomplete or unstable reaction can lead tothe formation of formic acid. Undesirable by-products and incomplete reactions not only negatively affect formaldehyde quality but also increase corrosion risks and maintenance efforts for the plant.

Since classical laboratory analyses are usually only carried out on a random sample basis, there is little room for quick and targeted process correction. In practice, this often leads to systems being operated with safety margins – at the expense of energy efficiency, raw material consumption, and cost-effectiveness. At the same time, the pressure is increasing to standardize processes, automate them, and make them independent of the pure empirical knowledge of individual employees.

Discover our solution!

Our solution: The LiquiSonic® Measurement system

Monitor concentration in real time

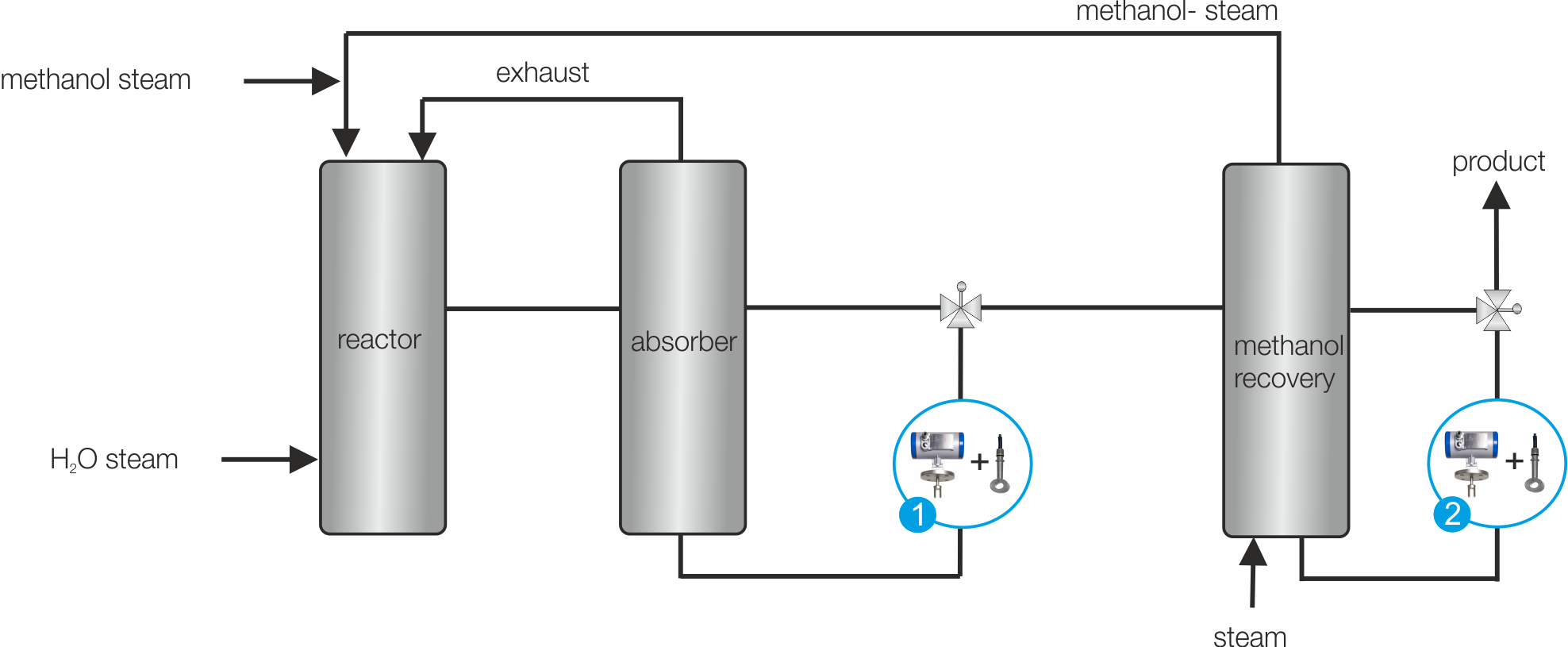

LiquiSonic® enables continuous inline measurement of methanol and formaldehyde concentrations directly in the process. Instead of waiting for sporadic laboratory values, all relevant information is available in real-time. The measurement system combines the measurement of sound velocity and density to capture even the smallest concentration changes with high precision. Thanks to the robust plug-and-play sensors, LiquiSonic® is specifically designed for continuous industrial operation in chemical plants. Different sensor lengths, process connectionsas well as digital and analog interfaces enable seamless integration into existing control systems. Process deviations are detected early. This allows targeted adjustment of reactions, minimization of by-products, and significant improvement of overall plant efficiency.

-

Continuous inline measurement

-

Early detection of wear

-

Transparency about reaction completeness

-

Optimization of oxidation conditions

-

Reduction of laboratory, energy, and raw material costs

Technical and economic details

Measuring principle

LiquiSonic® uses the physical property that the speed of sound in a liquid changes with its chemical composition. Each concentration of, for example, methanol, formaldehyde, or formic acid affects the speed of sound propagation in a characteristic manner. By combining the measurement of sound speed and density, a unique measurement value is created for the respective process liquid. This method is independent of optical properties such as color or turbidity and is therefore particularlyrobust against process fluctuations. Since no chemical additives are required, among other things, the measuring device is maintenance-free and the measurement is stable in the long term. Calibration is performed once and is product-specific, enabling very high measurement accuracy. This ensures reliable concentration monitoring directly in the ongoing process.

Economic benefit

Economic benefit

With LiquiSonic®, you reduce energy consumption by keeping the reaction process permanently in the optimal range. At the same time, methanol consumption can be reduced because overdoses can be immediately detected and avoided. Fewer by-products mean higher product quality and lower processing costs. Additionally, time-consuming and costly laboratory analyses are eliminated, relieving personnel and further increasing process safety.

-

Reduced energy consumption

-

Lower methanol consumption

-

Fewer unwanted by-products

-

Savings on laboratory and personnel costs

-

Higher system availability

Application example

Application example

In an industrial formaldehyde plant, LiquiSonic® is installed directly in the product stream. During ongoing operations, the system continuously monitors the methanol and formaldehyde concentration. If the residual methanol content rises above a certain threshold, the plant control system detects it early and allows timely response. In parallel, the measurement signal enables proactive process monitoring, allowing deviations to be compensated early. This prevents an incomplete reaction andthe resulting formation of formic acid to be avoided. By specifically adjusting temperature, air supply, or residence time, the reaction is now stabilized. The result: Consistent product quality, fewer unwanted by-products, and significantly extended service life. The customer additionally benefits from higher plant availability and lower operating costs.

Success stories and references:

You can obtain detailed case studies and customer references from our sales team. Feel free to contact us for specific application examples!

The main advantages at a glance

Transparency in the process

Continuous inline measurement provides immediately usable data without delay.

Sustainable cost reduction

Reduced energy, chemical, and laboratory costs through optimized process management.

Robust technology

Maintenance-free sensors designed for continuous operation under demanding process conditions.

Early detection of process deviations

Catalyst wear, over-oxidation, or the formation of formic acid become visible early.

Frequently asked questions

SensoTech GmbH is a leading company in the field of process measurement technology based in Barleben, near Magdeburg, Germany. We develop and produce innovative solutions for monitoring and optimizing industrial processes. Our specialization lies in the precise measurement of concentrations, densities, and other parameters in liquids - in real-time and directly during the process.

The system provides results in real-time. Based on the measurements, you receive a current measurement value every second. This fast response time enables effective process control during formaldehyde production and early detection of process deviations.

Our system uses ultrasonic transit time measurement to determine the speed of sound in the final concentration of formaldehyde, methanol, or by-products. This speed of sound directly correlates with the chemical concentration and enables measurement accuracies of ±0.05 wt%. The integrated temperature compensation ensures stable results even with fluctuating process conditions.

The LiquiSonic® measurement system is more robust, precise, and process-secure than conventional measuring devices. Our sensors are temperature compensated and offer a high long-term stability, so that they continuously provide reliable measurements even in variable process environments. The LiquiSonic® measurement technology also contains neither moving parts nor components that can wear out or be consumed. After installation, the measurement system is completely maintenance-free and drift-free. The sensors offer digital signal transmission up to 1000 m and enable continuous inline measurement without sample extraction. Other measurement methods, such as conductivity measurements, would not work with non-conductive resins.

The system is completely maintenance-free. There are no mechanical wear parts, seals, or optical windows that could be compromised. Regular calibration is not required - no drifting or sticking - our sensors remain stable for years.

Our sensors operate reliably in a temperature range from -40 °C to 200 °C and pressures up to 500 bar. With various material options such as stainless steel, Hastelloy, or PFA coatings, aggressive media can also be measured. Ex protection for Zone 1 and 2 is also available. We adapt the monitoring of your formaldehyde production to your conditions.

Yes, our sensors are also designed for extreme conditions. In addition to the extended temperature and pressure range, we offer custom adaptations such as sensor lengths up to 3000 mm, special alloys for corrosive media, and various protection types, for example, optional explosion protection. Each sensor is configured individually according to your requirements configured.

Since the speed of sound is affected by temperature, all our LiquiSonic® sensors are equipped with high-precision temperature sensors. This way, the influence of temperature on the measurement can be directly compensated Therefore, it is not necessary to integrate additional temperature sensors.

The system offers various digital interfaces (e.g., Profibus, Ethernet/IP, Foundation Fieldbus) as well as analog 4-20 mA outputs. The integration is carried out smoothly via standardized protocols.

Related articles

Blending of resins

When diluting polymer resins, precise adjustment of the final concentration is crucial for consistently high product quality. The LiquiSonic® measuring system continuously monitors the concentration via ultrasonic measurement and detects even the smallest deviations in real-time.

Polycondensation

Polycondensation represents the central step in polymer resin production and is particularly susceptible to fluctuations in the process. Even slight deviations in the reaction progress can lead to either too high a degree of cross-linking or too low a molecular mass.

Methanol

In the chemical, petrochemical, and pharmaceutical industries, methanol processing requires the highest quality standards. Even slight impurities can lead to costly production downtimes or quality issues.