Starch measurement in the paper industry

Concentration measurement of starch in sizing processes

Measurement accuracy: ± 0.05%

Wheat, corn, potato starch, etc.

No additional cleaning necessary

Plug & Play system

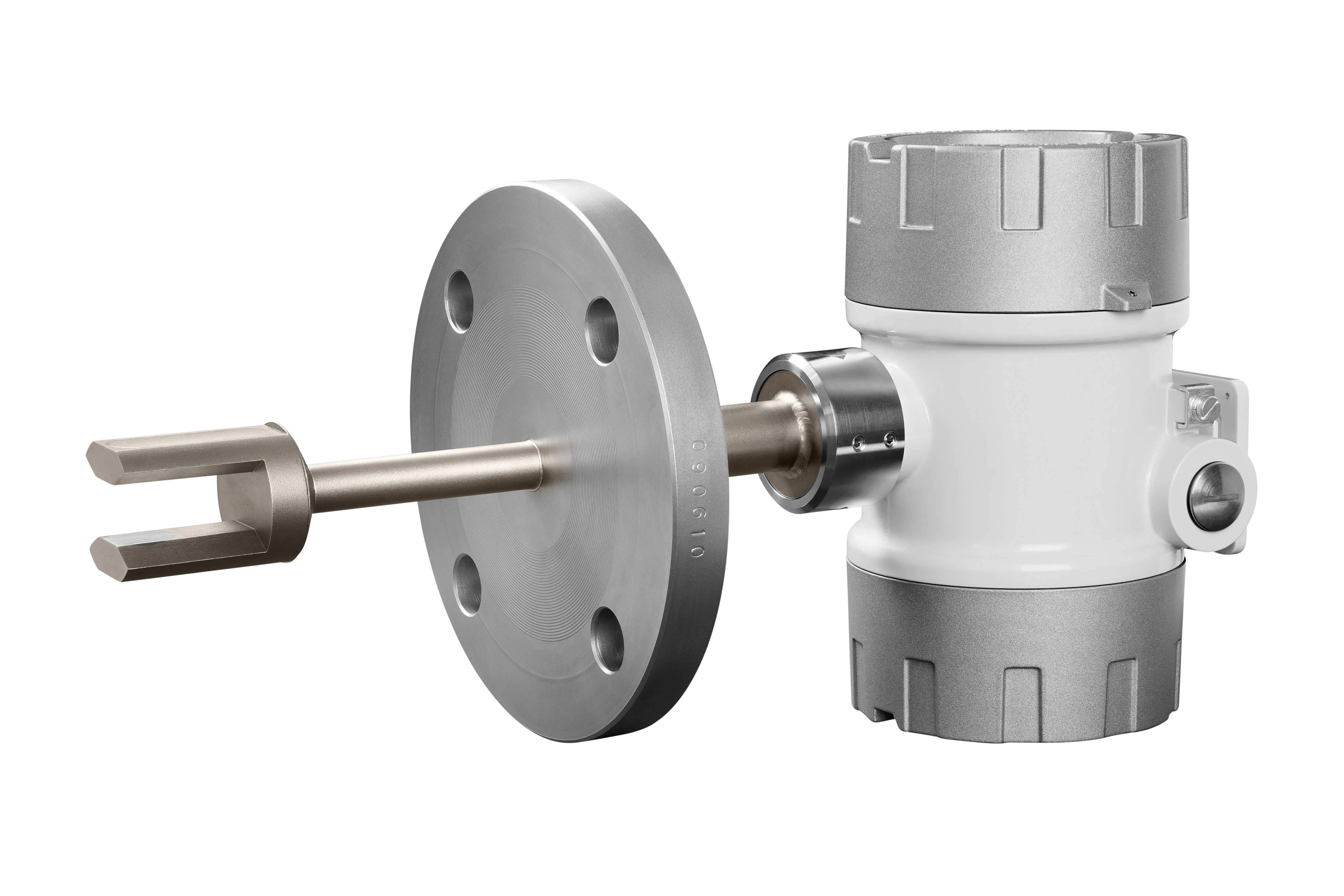

LiquiSonic® ensures precise analysis and monitoring of the starch concentration without additional cleaning steps, with an accuracy of ± 0.05% through ultrasonic measurements. The robust Plug & Play LiquiSonic® sensor design guarantees a long system life and reduces time-consuming laboratory measurements.

Exact and cleaning-free concentration measurement

In paper production, sizing is a critical process step. Desired properties such as tear resistance and dry strength are imparted to the paper. Therefore, process monitoring is particularly important to use the cost-intensive resources as efficiently as possible.

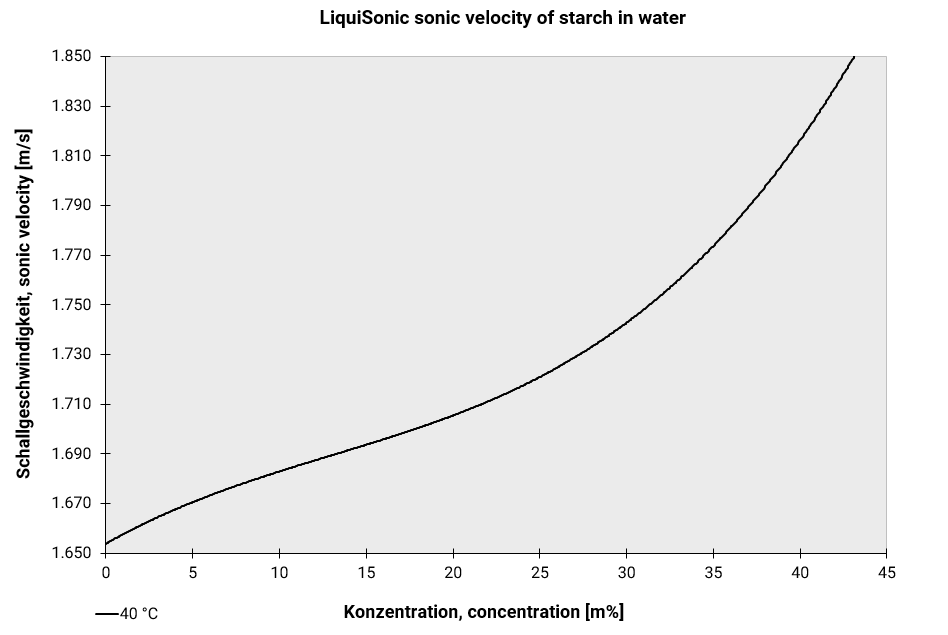

Eine einfache und schnelle Inbetriebnahme wird durch das Plug & Play System ermöglicht. Im Vergleich zu anderen Messverfahren liefern Ultraschallsensoren jederzeit ein eindeutiges Signal im typischen Konzentrationsbereich von 0 - 40 %, ohne dass aufwändige Reinigungs- und Spülvorgänge und kostenintensives Reinigungs-Equipment erforderlich wird. Zudem konnten bereits komplexe Messaufgaben für spezielle Papierstärkeleime mit Additiven oder Messungen über 40 m% Stärkegehalt erfolgreich realisiert werden.

Due to the permanent data logging of our durable LiquiSonic® sensors, time-intensive laboratory evaluations can be avoided and accuracies of ± 0.05% can be achieved to guarantee optimal process conditions at any time.

Plug & Play installation system

Our LiquiSonic® Immersion sensor is the perfect solution for precise measurement of starch concentration. Thanks to our Plug & Play system, the sensor can be installed directly into existing pipelines without elaborate modifications.

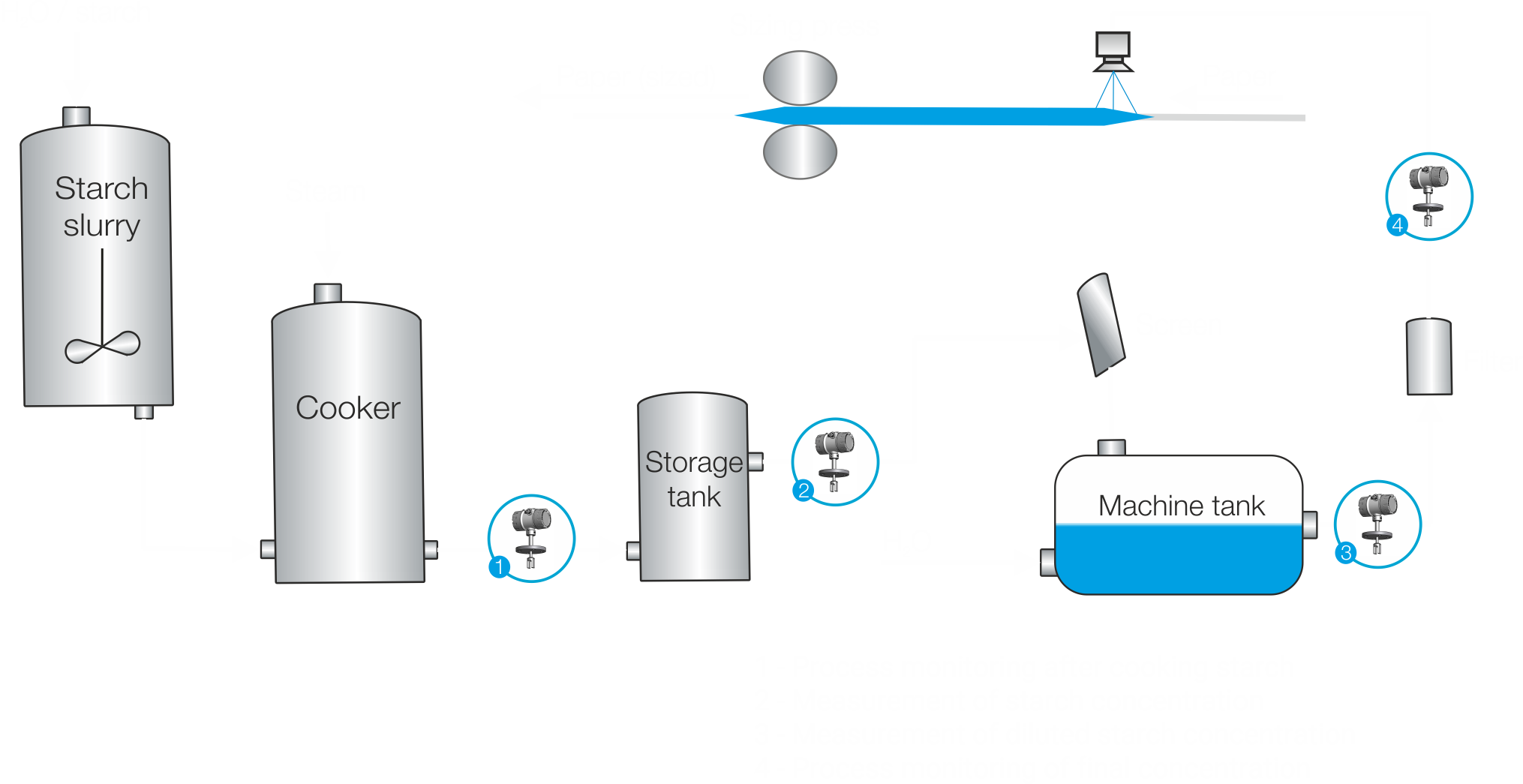

The LiquiSonic® Controller 30 allows the connection of up to four sensors, enabling permanent monitoring of starch concentration at several critical points with just one controller. This allows for very quick reactions to changes.

Our LiquiSonic® Immersion sensor can perfectly measure the typical concentration range of 0 - 40% as well as the classic process temperatures in the range of 20 - 60 °C. Furthermore, our system is suitable for a variety of starch types such as wheat starch, hydroxyethyl starch, potato starch, corn starch, and modified starch.

We solve your measurement task

Feel free to contact us.

We support you in solving your individual measurement task.