LiquiSonic® QC

LiquiSonic® QC is an analysis system that determines the concentration in a liquid without delay. The device is based on the highly precise measurement of absolute sound velocity and process temperature, allowing the analysis and monitoring of concentrations.

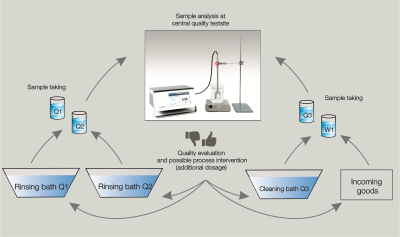

LiquiSonic® QC in Production

For processes and systems where inline measurement is not feasible and sample extractions for quality monitoring are necessary, SensoTech has created a smart solution. Especially for smaller volumes, inline measurement is often impractical and associated with expensive modifications. Therefore, the centrally developed quality measurement station by SensoTech is suitable for such systems. It is tailored to the individual concentration ratios at the respective measuring points in the production plant.

The system includes accessories that complete the measurement station and make it ready for immediate use - without complex installation or commissioning.

The sensor's electronics are integrated into the splash-proof controller. This evaluates the sensor data and visualizes it. Additionally, the sensor can be manufactured from different, durable materials for aggressive process fluids.

LiquiSonic® QC in Goods Receipt

For optimal cleaning results, ensuring high bath quality is essential. This begins with monitoring the delivered process fluids. Early detection of deviations or faulty products leads to quick reactions and thus to resource-saving production. With LiquiSonic® QC allows for easy and quick monitoring of delivered products directly upon goods receipt. As in the process, a sample of the liquid is taken directly on-site. Real-time measurement means that quality deviations are immediately detected and immediate action is possible. This allows for immediate detection of mix-ups and product quality fluctuations within different batches.

Functionality

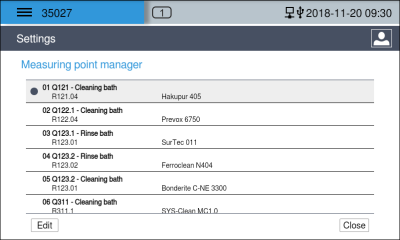

The clear measuring point management is ideal for managing and easily selecting samples/measuring points with just two clicks. Typically, several measuring points need to be checked in production facilities, which is why a digital measuring point is created in the device for each physical measuring point of a facility.

LiquiSonic® QC can manage 20+ different measuring points manage. Per measuring point, up to 1,000 measurements can be stored. Each measuring point has an individual configuration and can be field-adjusted. Measuring point name, product to be measured, and room designation are variably adjustable. Additionally, a laboratory value as a reference and a note can be assigned to each measuring point.

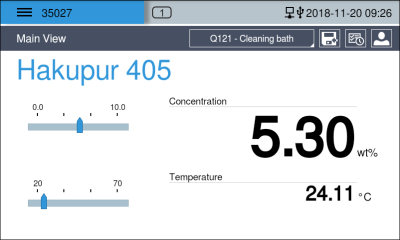

Limit value display

The quick and early detection of quality deviations avoids unnecessary costs. For simplification, the display of the central quality measuring station has optical support. The controller shows the Limit value display in the left part of the display. Deviations from the tolerances are color-coded at first glance. If the real-time measured value is outside the permissible limits, this is signaled with a warning notice and the deviation is documented by pressing the save button. Thus, high quality of cleaning, texturing, rinsing, and preservation baths or the delivered products is ensured.

Do you have questions?

When mixing bath chemicals from delivered concentrates and the solvent (e.g., water), monitoring of the initial concentration is necessary. This ensures economical use of materials while consistently adhering to quality-relevant parameters.

LiquiSonic® QC - The central quality measuring station

LiquiSonic® QC is an analysis system that determines the concentration in a liquid without delay. The device is based on the high-precision measurement of absolute sound velocity and process temperature, allowing for the analysis and monitoring of concentrations.

LiquiSonic® QC - The central quality measurement station | 8 MB