Precisely measure rolling oil concentration

for maximum product quality

for maximum product quality

With LiquiSonic® ultrasonic sensors, you monitor rolling oil concentrations inline and in real-time.

Immediately detect concentration fluctuations and save up to 15% of your operating costs.

±0.05% accuracy

Real-time measurement

Maintenance-free

Cost-saving

Why is rolling oil monitoring a critical challenge?

Fluctuating rolling oil concentrations directly affect product quality. They lead to surface defects, uneven material thickness, and increase scrap and rework effort. Additionally, batch deviations occur, jeopardizing process stability. Therefore, precise concentration control is crucial.

Worst case: Plant downtime and scrap

Our solution for precise rolling oil monitoring

LiquiSonic® rolling oil measurement system

The LiquiSonic® system continuously measures the sound velocity in your rolling emulsion and precisely determines the oil concentration - regardless of color, turbidity, or temperature.

Measurement accuracy ±0.05 wt%

- More precise than all optical methods

Inline measurement without sampling

- Directly in the main inlet to the rolling stand

Hydraulic oil detection

- Immediate warning in case of leaks

Completely maintenance-free

- No moving parts, no calibration

Successfully measured rolling oils

Successfully measured rolling oils

| Manufacturer | Rolling oil | Measurement range | Temperature |

|---|---|---|---|

Quaker Houghton | Quakerol NH 6786 | 0-15 wt% | 20 - 70 °C |

Quaker Houghton | Rolkleen 1553 E | 0-20 wt% | 50 - 80 °C |

Henkel | Bonderite L-RO6530 | 0-5 wt% | 40 - 60 °C |

Henkel | Gerolub 71 | 0-20 wt% | 50 - 80 °C |

WIN Group | BW SYNROL-500K | 0-10 wt% | 55 - 65 °C |

Fuchs Group | TRENOIL S838 | 0-5 wt% | 30 - 60 °C |

Castrol | Iloform RS 4060 | 0-10 wt% | 30 - 60 °C |

San-I Chemical | Yushiroble SER-100H | 0-10 wt% | 40 - 60 °C |

Technical details and specifications

Ultrasonic measurement principle in detail

Physical measurement principle

The LiquiSonic® system measures the absolute sound velocity in the rolling emulsion with a resolution of 0.01 m/s. The sound velocity is a unique physical quantity that correlates with the concentration, independent of density.

Independence from Interference Factors

Unlike other measurement methods, ultrasonic measurement is independent of:

- Color and turbidity of the emulsion

- Metal particles and impurities

- Bubble formation in the medium

- Lighting conditions and contamination

- Electrical conductivity

Economic Benefit

Cost Savings:

-

Reduce consumption

-

Fewer laboratory analyses required

-

Reduction of production waste

Amortization:

-

8-12 months typical amortization period

-

Avoidance of costly plant shutdowns

Risk Minimization:

-

Reduction of unplanned downtimes

-

Continuous quality control

-

Predictive maintenance instead of reactive maintenance

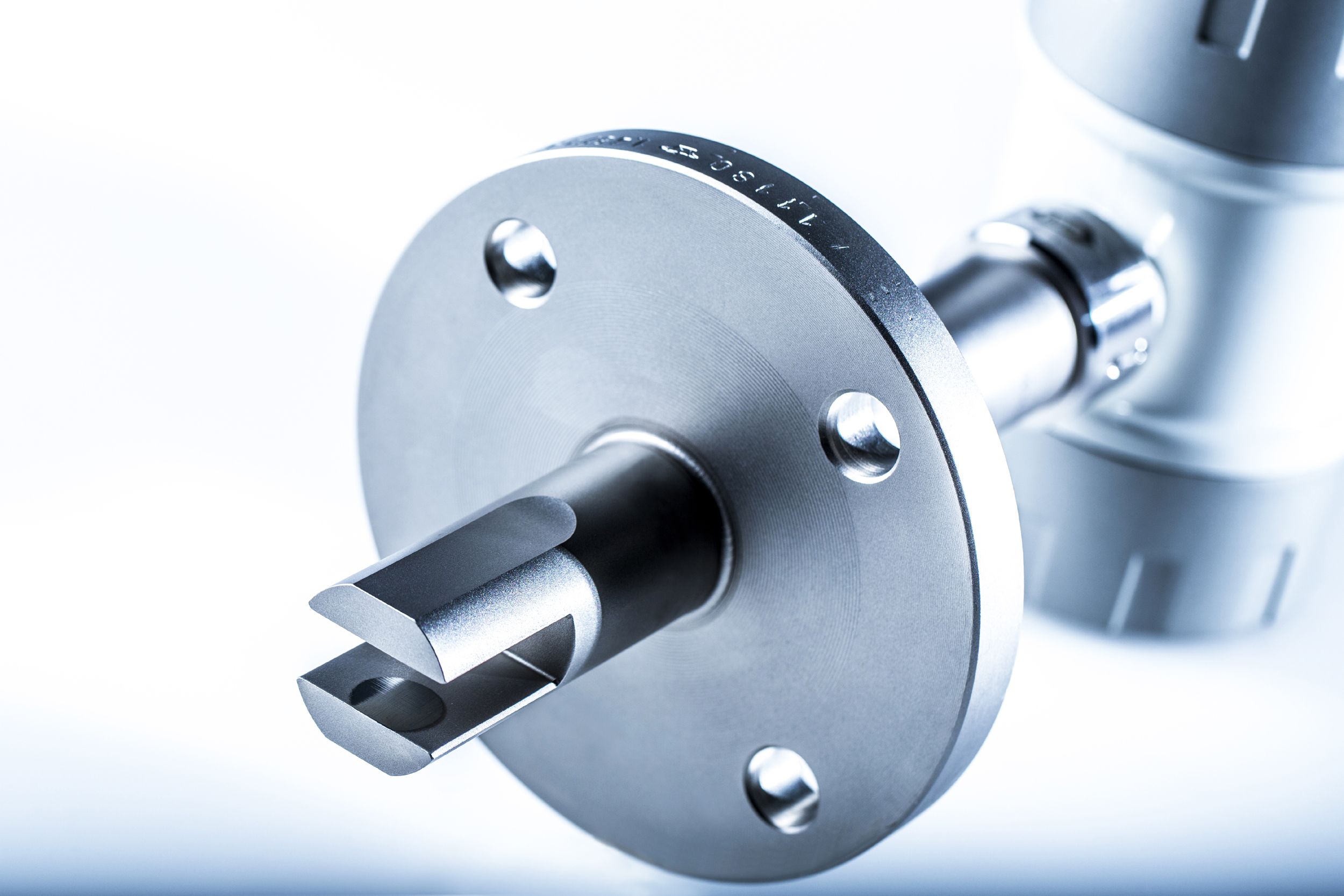

Individual sensor customizations

Individual sensor customizations

SensoTech manufactures sensors individually according to your process requirements - from standard applications to extreme operating conditions.

Available material variants

- Stainless steel 316L - Standard for most applications

- Hastelloy C-276 - for aggressive chemicals

- Titanium Grade 2 - for chloride-containing and abrasive media

- PFA/PVDF coating - for highly corrosive applications

Flexible design options

- Installation lengths: 50 mm to 3000 mm (and more on request)

- Process connections: all common flanges and threads

- Pressure ranges: up to 500 bar

- Explosion protection: ATEX Zone 1 and 2 available

Technical specifications

Measurement range concentration | 0.1 - 100 wt% |

Measurement accuracy | typically ±0.05 wt% |

Repeatability | ±0.02 m/s |

Temperature range | -40 °C to +200 °C |

Pressure range | up to 500 bar |

Digital transmission | up to 1,000 m |

Interfaces | 4-20 mA, Profibus, Ethernet, Modbus, Fieldbus, ... |

Protection class | IP65 & explosion protection available |

Calibration | Factory calibration |

Maintenance | Completely maintenance-free |

Practical examples from the rolling industry

Aluminum cold rolling mill

A leading aluminum producer installed LiquiSonic® sensors to monitor its rolling emulsion with 2-8 wt% rolling oil content.

Challenge: Frequent quality fluctuations due to manual oil addition

Solution: Continuous inline measurement with automatic dosing

Result: Reduction of oil consumption, fewer surface defects

Steel rolling mill with hydraulic oil problem

A steel producer suffered from recurring hydraulic oil leaks that affected the quality of the rolling oil.

Challenge: Late detection of leaks led to annealing defects

Solution: LiquiSonic® with hydraulic oil detection algorithm

Result: Immediate warning in case of sudden oil entry

Further success stories and references:

Detailed case studies and customer references are available from our sales team. Contact us for specific application examples from your industry.

Your benefits at a glance

Surface quality

Consistent rolling oil concentration for perfect surface results

Shorter downtimes

Reduced setup and maintenance times through optimal process management

Fewer laboratory tests

Significantly fewer tests through continuous online monitoring

Longer service life

Longer use of the rolling oil emulsion possible

Seamless documentation

Automatic data collection for quality evidence

Cleaner rolled material

Less reworking through optimized process parameters

Frequently asked questions

Typical payback periods are between 6-12 months. The savings are achieved, for example, through reduced oil consumption, less waste, shorter downtimes, and optimized process management.

The measurement accuracy for rolling oil concentrations is ±0.05 wt%. This is significantly more precise than conventional measurement methods, especially with contaminated or turbid emulsions. Our ultrasonic technology is independent of color, particles, or gas bubbles in the medium.

Yes, LiquiSonic® sensors can be easily integrated into existing pipelines. Installation is usually carried out in the main line to the rolling mill. Various flange and thread connections are available.

No, the LiquiSonic® system is completely maintenance-free. The sensors have no moving components or wear parts and therefore do not require regular calibration. The factory calibration remains stable throughout the entire operating period, which also has a positive effect on operating costs.

The LiquiSonic® system is designed for extreme conditions. It can cover temperatures from -40 to 200 °C and pressures up to 500 bar can be covered. The sensors are completely maintenance-free and designed for continuous use in industrial environments.

The system works with all common rolling oils and emulsions for steel, aluminum, copper, and other metals. Over 50 different rolling oil formulations have already been successfully measured. New oils can be characterized at any time in the SensoTech laboratory.

The system offers all common industrial interfaces: 4-20 mA, Profibus, Ethernet, Modbus, Fieldbus and others. Digital transmission is possible without interference up to 1,000 m. Integration into existing systems is straightforward.

SensoTech is a specialist in ultrasonic concentration measurement with over 35 years of experience. The patented technology, maintenance-free sensors, and customer-specific, individual customization options for the sensors make us one of the leading providers in this field.