Concentration

and Density

measure inline

News

Free Webinar: Incoming Goods Inspection with LiquiScope

Nehmen Sie an unserem kostenlosen Webinar teil und erfahren Sie, wie LiquiScope eine Echtzeit-Inline-Identifikation von Flüssigkeiten ermöglicht. Entdecken Sie, wie Fehllieferungen und Verwechslungen sofort erkannt werden können, wie die Flüssigkeitsidentität in Echtzeit eindeutig angezeigt wird und wie sich LiquiScope nahtlos in bestehende Prozesse in einer Vielzahl von Branchen integrieren lässt.

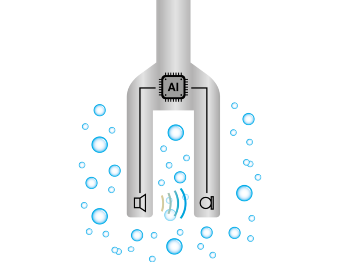

Reliable Gas Bubble Detection in Liquid Processes

In many industrial processes, early and reliable detection of gas bubbles plays a crucial role. Even the smallest bubbles can disrupt the sound signal and distort measurements. Therefore, we have adapted the design of our sensors to meet this challenge.

Discover our latest innovation - LiquiScope!

LiquiScope – Your solution to avoid misfillings and make processes safer.

Upcoming Events

SensoTech is the specialist for the analysis and optimization of process engineering processes in liquids. Since its founding in 1990, we have developed into the leading company for measuring devices for inline determination of concentrations in liquids.

Our analysis systems set the trend – worldwide.

LiquiSonic® measures the density or concentration of a liquid using the speed of sound. The measurement method is independent of conductivity, color, refractive index, or transparency of the liquid.

We offer our customers various versions that are adapted to the different areas of application.

We have the solution to your problem!

We have the solution to your problem!

SensoTech is the specialist in manufacturing measuring devices for inline determination of concentration and density in liquids. These use the speed of sound to analyze the liquids.

Our measurement systems are used in various processes in industries such as the chemical industry, pharmaceutical industry, food industry, and many others. Customers from all over the world trust the expertise and quality of our LiquiSonic® Measuring devices to optimize their processes and deliver highly accurate measurement results even under the most difficult conditions.

After installation and commissioning, we are at your side as a competent partner for all questions regarding your system. First-class service is an important support for us alongside the development of state-of-the-art measuring devices to meet our quality standards.

In addition to first-class products and extensive service, we offer our customers a range of events and webinars. An established network and our numerous international representations in all important geographical markets of the world, where our expertise is expanded, are the basis for innovative solutions that set standards in the market.

SensoTech GmbH

Steinfeldstr. 1

39179 Magdeburg-Barleben

Germany

T +49 39203 281 100

F +49 39203 281 109

SensoTech Inc. USA

69 Montgomery Street, Unit 13218

Jersey City, NJ 07303

T +1 973 832 4575

SensoTech (Shanghai) Co., Ltd.

Room 609, Bldg.1, No.778, Jinji Road. Pilot Free Trade Zone,

201206 Shanghai

China

T +86 21 6485 5861

M +86 13 6551 83644

www.sensotech-cn.com