Alkaline electrolysis

LiquiSonic® in determining the concentration of caustic potash

LiquiSonic® offers you a highly accurate measurement of caustic potash concentration, advanced gas bubble detection, and easy integration into existing systems. This ensures maximum efficiency, minimal downtime, and full transparency in your process.

Measurement accuracy ±0.05 wt%

Measurement range 0–max. wt%

Gas bubble detection

High resistance

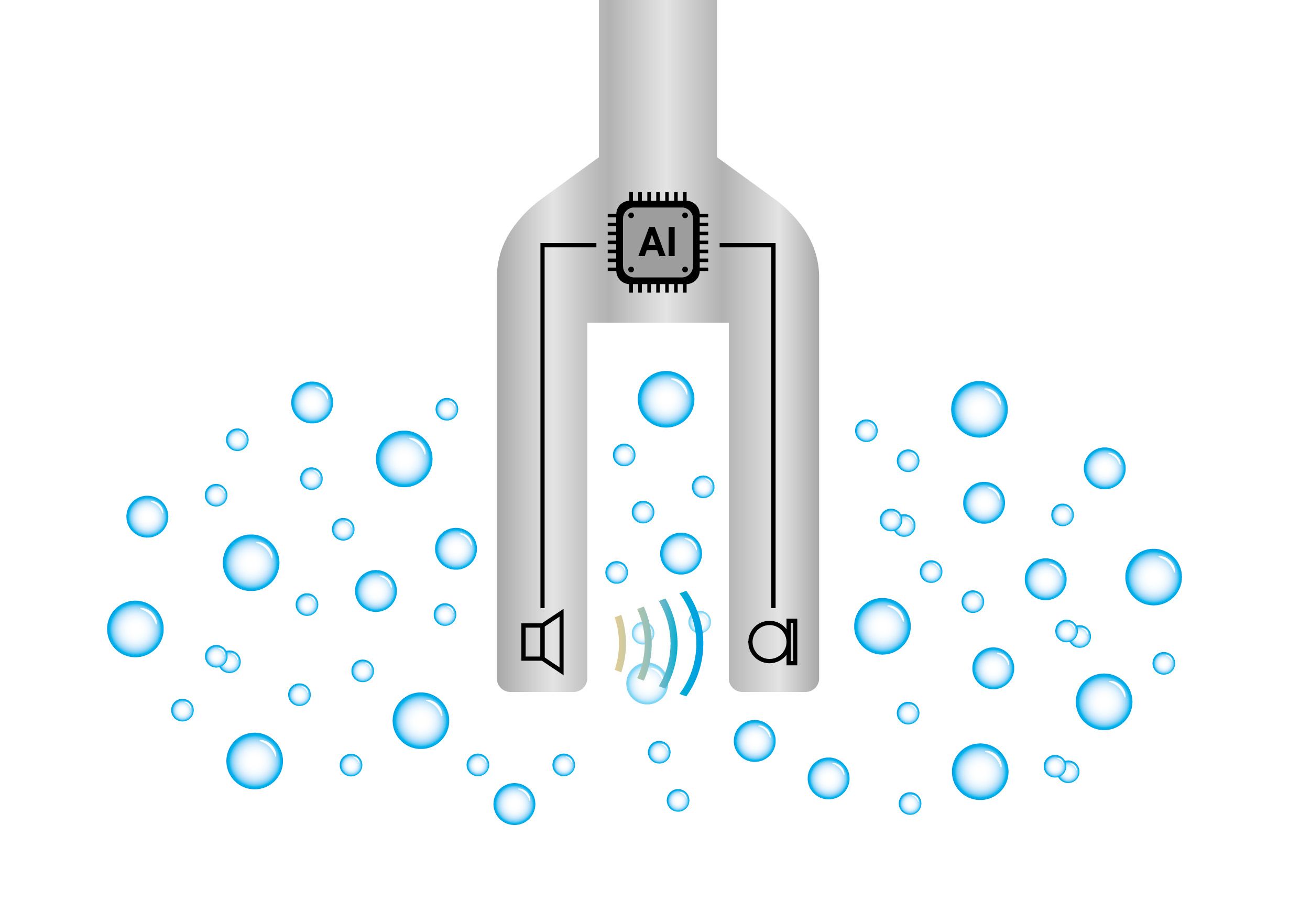

Innovative gas bubble detection

Gas bubbles are an unavoidable byproduct of electrolysis – and a major challenge for precise measurement technology. Even the smallest bubbles can disrupt the sound signal and distort measurements if not properly accounted for. This can lead to unnoticed measurement errors in conventional systems that can affect process control.

SensoTech has therefore adapted the sensor design to meet this challenge. The combination of innovative architecture and intelligent signal processing ensures that gas bubbles are detected, their influence compensated for, and the measurement results reliably displayed. Using AI algorithms, the signal changes caused by gas bubbles are analyzed and corrected, allowing the user to obtain a clean, reliable measurement result.

Furthermore, the technology goes a step further: it quantifies the amount of gas bubbles and presents this as a reproducible measurement variable. This allows changes in the process, such as unusually high gas production or disturbances in gas separators, to be detected at an early stage. This enables quick diagnosis, reduces downtime, and improves plant availability.

With this function, operators always have a clear overview of the state of their electrolysis and can react immediately to deviations – a decisive advantage for safe, efficient, and stable hydrogen production.

Optimization of efficiency

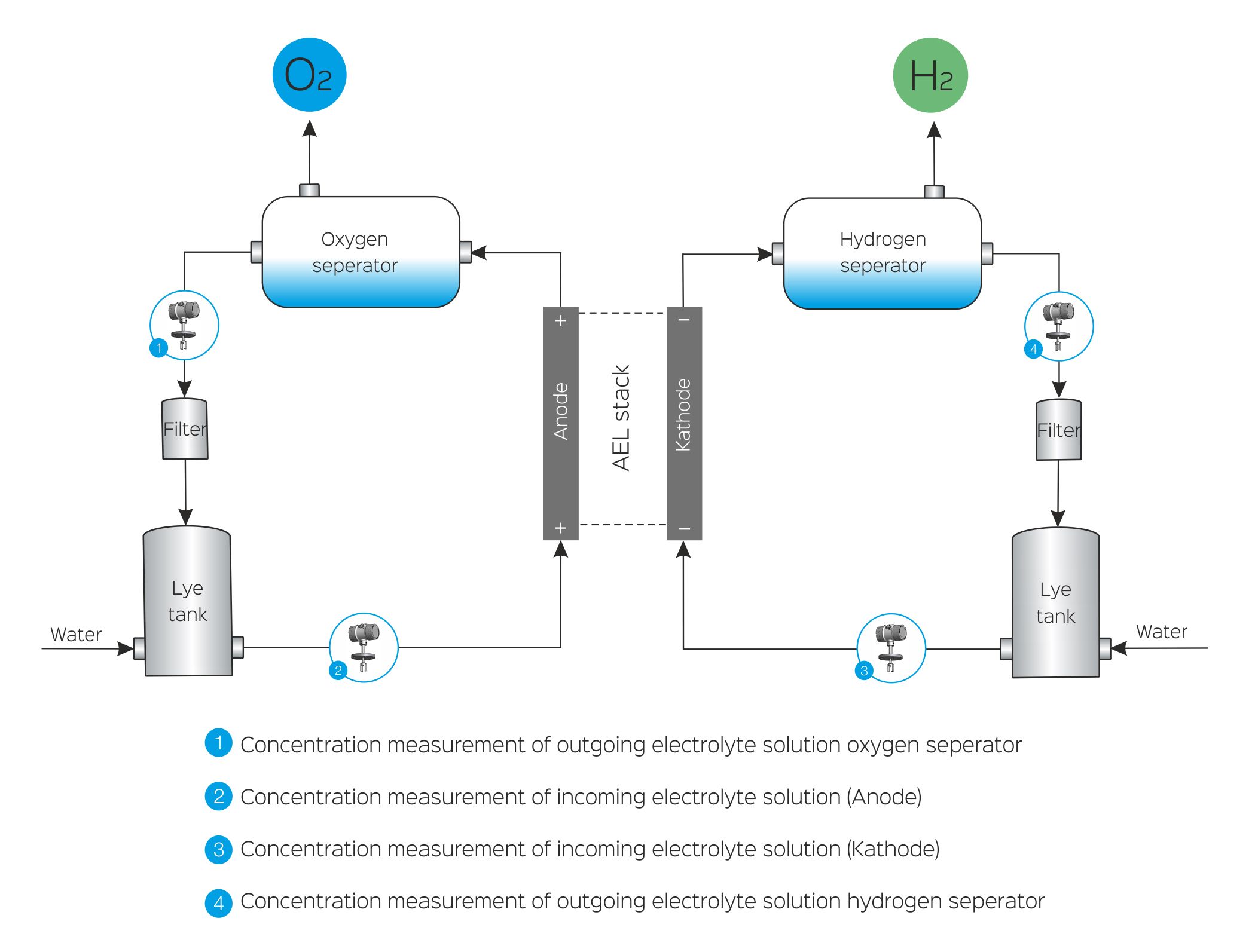

The concentration of caustic potash is a central process parameter in alkaline electrolysis and has a direct impact on the efficiency of hydrogen production. If the concentration is too low, the efficiency of power conversion decreases; if it is too high, energy demand increases and the lifespan of electrolysis cells can be shortened. Even the smallest fluctuations can have significant effects on yield and operating costs.

With LiquiSonic® you measure the KOH content continuously and with the highest precision over the entire range, from 0% to saturation. The ultrasonic measurement method provides a stable signal, independent of the color, turbidity, or conductivity of the liquid. The accuracy of ±0.05 wt% ensures that the process is run optimally and resources are used in the best possible way.

Another advantage: Thanks to continuous measurement directly in the process, time-consuming sampling and laboratory measurements are eliminated. This not only saves time but also increases process safety, as measurement values are available in real-time. The robust, low-maintenance plug-and-play design ensures a long system lifespan and a quick return on investment.

Installation according to your wishes

Electrolyzers are not all the same – concentrations, temperatures, flow rates, and plant configurations vary from operator to operator. LiquiSonic® is therefore developed to easily cover these individual differences.

Our sensor reliably measures across the entire concentration range from 0% to saturation and remains stable even at high process temperatures of up to 120 °C. This makes it ideal for the classic concentration range of 20–40 wt% KOH at temperatures between 50 and 85 °C, as is typical in alkaline electrolysis.

The installation is straightforward: The LiquiSonic® immersion sensor is installed directly into existing pipelines without major modifications. Via the LiquiSonic® Controller 30 up to four sensors can be operated simultaneously, allowing multiple electrolyzers to be monitored with just one system. Continuous data recording enables seamless documentation and facilitates process optimization.

Customer-specific requirements – from special installation situations to interface adjustments and extended reporting options – can also be implemented. This way, you get a measurement solution that is precisely tailored to your processes.

We solve your measurement task

Feel free to contact us.

We support you in solving your individual measurement task.