Concentration measurement

in the

semiconductor industry

in the

semiconductor industry

Concentration monitoring for semiconductor processes – for efficient production, stable processes, and highest quality.

Up to ±0.02 wt%

Real-time measurement

Maintenance-free

Cost-saving

Challenges in concentration measurement in semiconductor processes

In semiconductor manufacturing, the exact ratio of chemical concentrations is crucial, but traditional lab analyses often deliver results too late. With LiquiSonic® SensoTech enables reliable real-time monitoring that can be easily integrated into existing processes. The system delivers precise, maintenance-free measurement data, thus enhancing process safety and efficiency.

Challenges

-

Chemical concentrations not within the target range

-

Time-consuming laboratory analyses

-

No immediate and reliable information on chemical composition

Solution: LiquiSonic®

-

Clear monitoring with LiquiSonic®

-

Immediate display of chemical concentration

-

Seamless integration into existing systems

-

Maintenance-free and without consumables

Your advantages

-

Traceable and reliable measurement results

-

Measurement results in real-time

-

Completely maintenance-free sensors and chemical-resistant materials

-

Easy integration into systems of any size and configuration

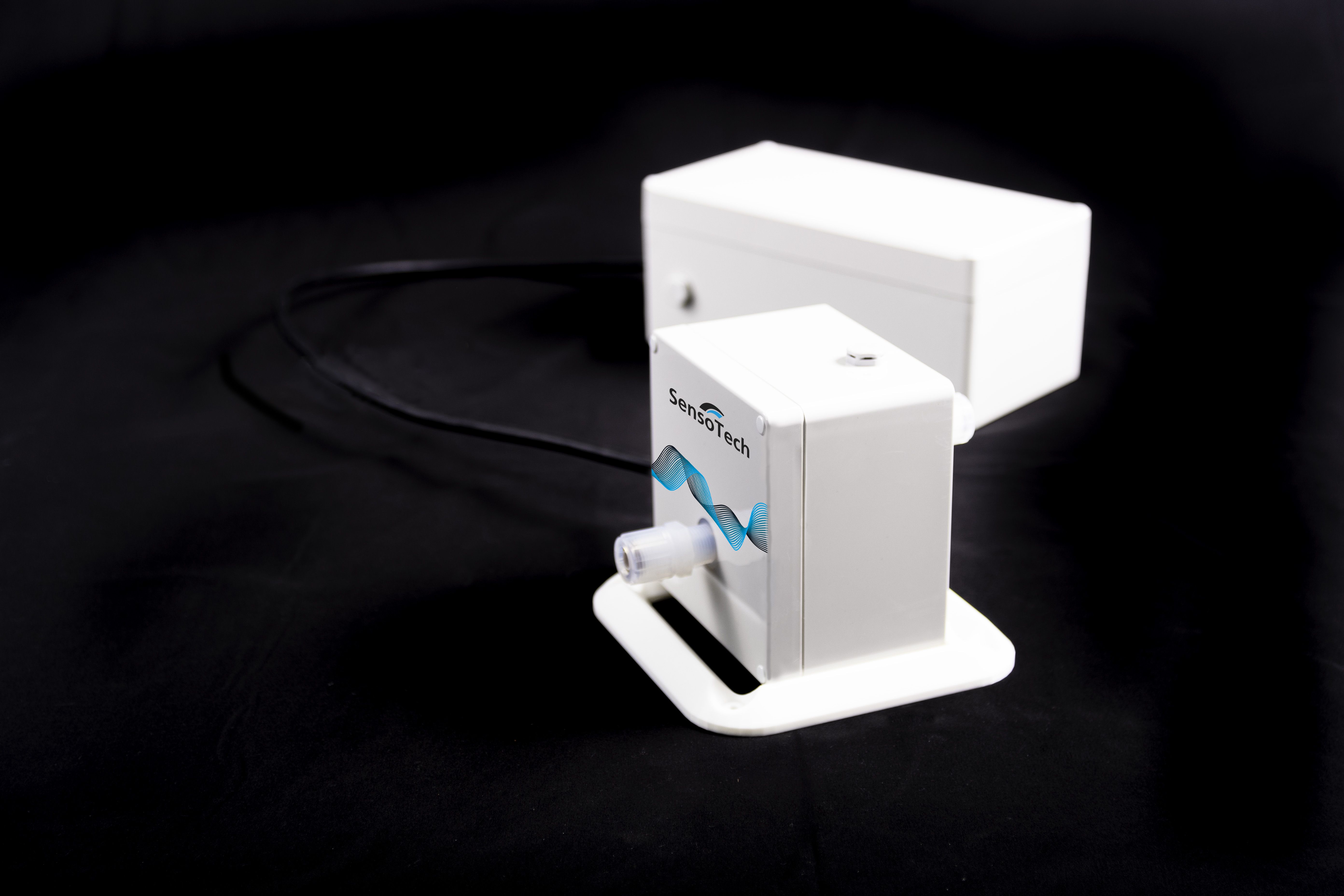

Our solution: The LiquiSonic® measurement system

Monitor concentration in real-time

LiquiSonic® combines modern ultrasonic technology with temperature-compensated measurement to deliver precise results for critical chemical mixtures in semiconductor manufacturing. Real-time monitoring ensures stable product quality, reduces deviations, and provides data for process optimizations. This lowers operating costs and chemical consumption while increasing process safety and efficiency.

-

Ensure quality: Real-time monitoring guarantees precise results without deviations.

-

Reduce costs: Optimized processes for maximum reliability and lower consumption.

-

Increase efficiency: Higher product quality with reduced operating costs.

Technical details and specifications

Ultrasonic measuring principle

The speed of sound in liquids is directly related to the concentration of dissolved substances. High-precision time measurements allow for an exact determination of the concentration.

Conductivity integration

In three-component systems, conductivity is used as a second physical parameter to uniquely determine both concentrations.

Temperature compensation

Two PT1000 sensors integrated into the measuring cell ensure automatic temperature compensation and thus precise measurements under all conditions. By directly capturing the process temperature, the speed of sound is corrected in real time, which improves stability and accuracy even with fluctuations.

Economic benefit

Real-time concentration measurement enhances quality, efficiency, and reliability, while simultaneously reducing costs and resource consumption:

-

Reduced operating costs through lower chemical consumption and fewer laboratory analyses

-

Less waste and rework, as deviations can be immediately detected and corrected

-

Stable product quality ensures competitiveness and reduces complaints

-

More efficient processes through real-time data instead of delayed laboratory measurements

-

Higher system availability through maintenance-free sensors without consumables

-

Process optimization through precise data leads to continuous improvement and better resource utilization

-

Fast ROI thanks to savings in energy and operating costs

Technical specifications

Measurement accuracy | Up to ±0.02 wt% |

Temperature range | 5 °C to 60 °C |

Pressure range | Up to 4 bar |

Material & coating | PFA |

Digital transmission | Up to 1,000 m (more on request) |

Interfaces | 4-20 mA, Profibus, Ethernet, Modbus, Fieldbus, ... |

Protection class | IP65 |

Calibration | One-time factory calibration |

Maintenance | Completely maintenance-free |

Application examples

Typical chemical process steps and our used process solutions for cleaning and etching processes as well as special etching and development processes:

SC-1 (APM)

NH4OHHydrogen Peroxide2O2

SC-2 (HPM)

HCIHydrogen Peroxide2O2

SPM (Piranha)

H2SO4Hydrogen Peroxide2O2

Oxide Removal (DHF)

Hydrofluoric Acid

Oxide Removal (BOE/BHF)

Hydrofluoric Acid/NH4F

Si₃N₄ Etching

H3Phosphoric Acid4

Isotropic Silicon Etching

HFHydrogen PeroxideNO3

Anisotropic Silicon Etching (MEMS)

KOH/Si

TMAH/Si

Photoresist Development

TMAH

Nitric Acid / Acetic Acid

HNO3Carbon Hydrogen3Carboxylic Acid

HF / HCl

HFHydrogen PeroxideCl

Success Stories and References:

Detailed case studies and customer references are available from our sales team. Contact us for specific application examples from your industry.

Key Benefits at a Glance

Consistent Quality

Real-time monitoring prevents deviations and ensures consistent product quality.

Cost Savings

Reduced chemical consumption and lower operating costs through optimized processes.

Highest Efficiency

Real-time data enables faster decisions and optimized workflows.

Maintenance-free

Sensors are chemical-resistant and require no consumables.

Frequently Asked Questions

SensoTech GmbH is a leading company in the field of process measurement technology based in Barleben, near Magdeburg, Germany. We develop and produce innovative solutions for monitoring and optimizing industrial processes. Our specialization lies in the precise measurement of concentrations, densities, and other parameters in liquids - in real-time and directly during the process.

Unlike optical methods, which are influenced by color or turbidity, conductivity-based methods, which are sensitive to electrical conductivity, or density-based methods, which can be disturbed by temperature or gas bubbles, our ultrasonic method is independent of these influences.

The LiquiSonic® measurement technology also contains no moving parts or components that can wear out or be consumed. Therefore, after installation, the measurement system is completely maintenance-free and drift-free.

The sensors offer digital signal transmission up to 1000 m and enable continuous inline measurement without sample extraction.

Our system uses ultrasonic transit time measurement to determine the speed of sound in liquids. This speed of sound directly correlates with the chemical concentration and enables measurement accuracies of up to ±0.02 wt% for the semiconductor industry. The integrated temperature compensation ensures stable results even under fluctuating process conditions.

The system delivers results in real-time. It performs over 30 measurements per second. Based on these measurements, you receive an updated measurement value every second. This fast response time enables effective process control and early detection of deviations.

Our semiconductor sensors operate reliably within a temperature range of 5 °C to 60 °C and pressures up to 4 bar.

Yes, by combining the speed of sound measurement with additional physical quantities (e.g., conductivity), multiple components can be determined simultaneously. This allows for monitoring of additional additives in semiconductor manufacturing.

The semiconductor measurement system is completely maintenance-free. There are no mechanical wear parts, seals, or optical windows that could be affected. Regular calibration is not required - the LiquiSonic® sensors remain stable for years.

The system offers various digital interfaces (e.g., Profibus, Ethernet/IP, Foundation Fieldbus) as well as analog 4-20 mA outputs. The integration is seamless via standardized protocols.

Since the speed of sound is affected by temperature, our LiquiSonic® sensors are equipped with high-precision temperature sensors. This allows the influence of temperature on the measurement to be directly compensated Therefore, it is not necessary to integrate additional temperature sensors into the semiconductor process.

Related applications

Texture and etching baths

In etching baths, material layers are selectively removed to create desired surface structures.

PCB cleaning

Cleaning removes organic residues, particles, and oxides to ensure that the circuit traces can be processed reliably.

Pickling bath monitoring

Pickling baths dissolve oxides or impurities from metal surfaces and must be kept constantly within the correct concentration range.

Green liquor monitoring

Green liquor is a highly alkaline byproduct in paper manufacturing, and its concentration must be monitored for stable subsequent processes.

Acid concentration measurement

The precise determination of concentrations in aggressive chemicals is crucial for controlled and safe reactions.

Gas scrubbers

In gas scrubbers or neutralization plants, pollutants are removed from exhaust air or liquids, requiring precise control of the chemicals used.