Process optimization in the

Polycondensation

Polycondensation

Polycondensation is the most important step in the production of polymer resin. LiquiSonic® provides precise monitoring and analysis of your processes - completely maintenance and drift-free.

Reaction monitoring

Real-time measurement

Wartungs- & driftfrei

Cost-saving

Challenges in polycondensation

Polycondensation represents the central step in polymer resin production and is particularly susceptible to fluctuations in the process. Even slight deviations in the reaction progress can lead to either too high a degree of crosslinking or too low a molecular mass. The result is brittle and unusable resin with insufficient mechanical properties. To prevent rejects, precise control of viscosity and degree of crosslinking is therefore crucial. In addition, the precise determination of the reaction progressis technically very demanding.

Challenges

-

Exact control of the reaction progress required

-

Too much cross-linking leads to brittle, unusable resins

-

Too low molecular weight causes insufficient mechanical properties

-

Laboratory measurements are delayed and do not provide continuous data

-

Narrow process window: Even small deviations lead to rejects

Solution: LiquiSonic®

-

Continuous ultrasonic measurement of the reaction progress in real time

-

High accuracy through temperature-compensated sound velocity measurement

-

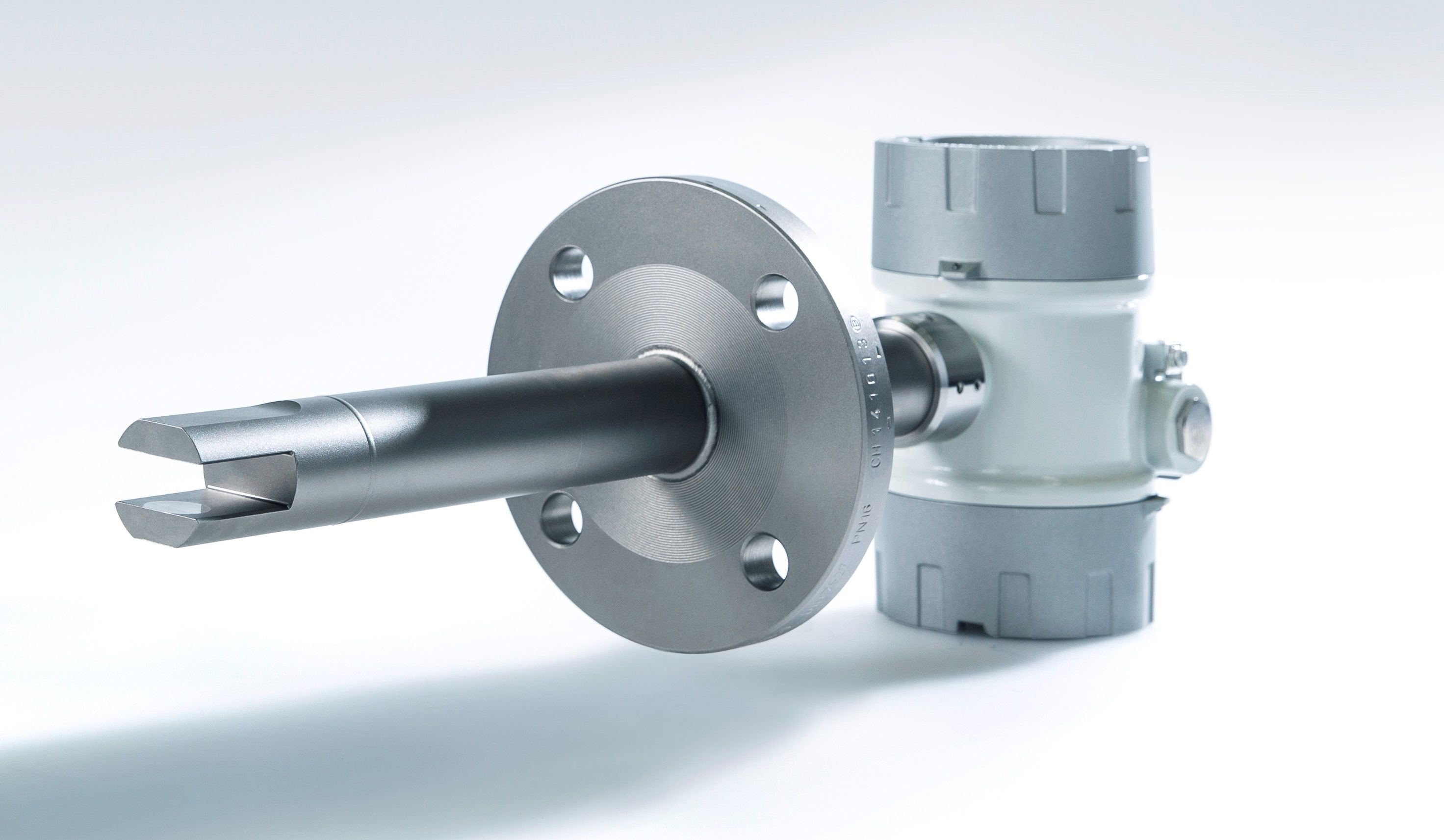

Robust sensor design, adaptable to individual process conditions

-

Automated data acquisition and evaluation for seamless process documentation

-

Integration into process control systems via digital and analog interfaces

Your advantages

-

Consistent product quality through real-time monitoring

-

Reduction of rejects through precise process control

-

Reduction of time-consuming analyses, higher process efficiency

-

Stable, maintenance-free, drift-free, and cleaning-free sensors

-

Sustainable and economical polymer resin synthesis

Our solution: The LiquiSonic® Measurement system

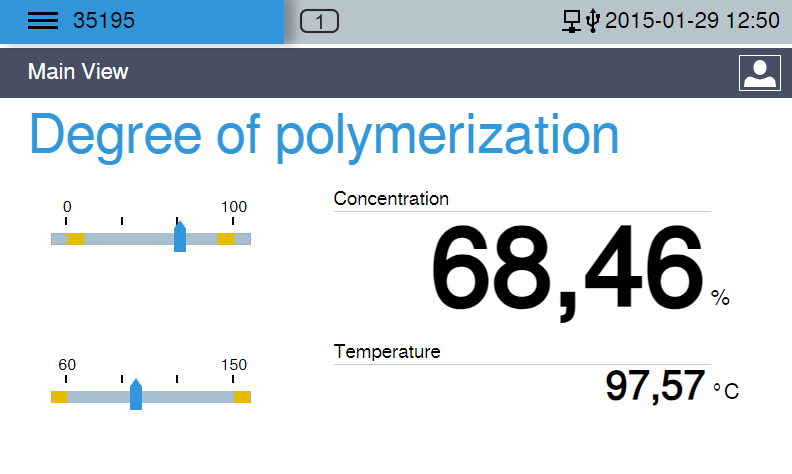

Monitor concentration in real time

LiquiSonic® solves the central challenges of polycondensation in polymer resin production through continuous and highly precise ultrasonic measurement of the reaction progress. Since the speed of sound directly correlates with the concentration and properties of the resin, critical deviations can be detected early and corrected immediately. The robust sensor design allows direct installation in reactors or pipelines and provides temperature-compensated real-time data, which can be automatically documented andtransferred to the process control system. In this way, reaction parameters can be better regulated, laboratory analyses reduced to a minimum, and constant quality ensured. An above-average sensor length is often used, which (as one of many customization options of the measurement system) allows optimal integration into your specific process.

-

Continuous, precise real-time monitoring

-

Robust, temperature-compensating sensor design

-

Flexible customization options

Technical and economic details

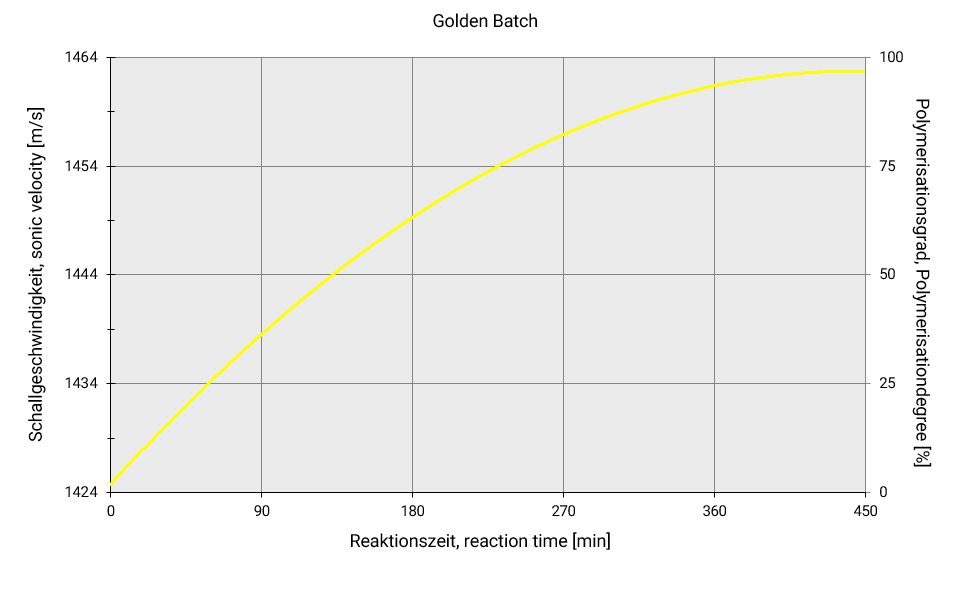

Ultrasonic measuring principle

The ultrasonic measurement method of LiquiSonic® is based on a highly precise time measurement. From the measured sound transit time and the known distance between transmitter and receiver, the sound velocity is calculated, which is directly related to the concentration and properties correlates with the polymer resin. This allows the progress of the reaction during polycondensation to be determined continuously and in real time – a decisive advantage over laboratory-based methods. Although viscosity measurement is traditionally considered the standard method in polycondensation, it is slower, less sensitive to concentration fluctuations (especially at high concentrations), and leads to sticky sensors during inline measurement. The ultrasonic method ultimately provides a more stable measurement andis also completely drift-free, maintenance-free, and requires no cleaning.

In this waya consistently high quality of the resin is ensured and the process management is sustainably optimized.

Economic Benefit

Economic Benefit

In addition to the technical advantages, the use of LiquiSonic® also offers significant economic potential:

-

Reduction of scrap by immediate detection of incorrect mixtures

-

Optimized raw material consumption thanks to precise dosing and optimized final concentrations

-

Faster reaction times in case of process deviations, minimizing downtime

-

Savings of energy and operating costs through more efficient process management

-

Reliable documentation through automatic data storage

-

Higher plant availability through robust, drift-free, maintenance-free and cleaning-free sensors

-

Fast ROI through reduced operating costs and higher process stability

Application example

Application example

Polycondensation is the most important step in the

production of polymer resin. Nur bei korrekter Viskosität kann das Polymerharz für die gewünschte Anwendung genutzt werden. Das LiquiSonic® Measurement system überwacht die Konzentration kontinuierlich per Ultraschallmessung und erkennt selbst kleinste Abweichungen in Echtzeit. Dadurch lassen sich Fehlmischungen vermeiden und der Materialeinsatz exakt steuern. Die robuste Plug-&-Play-Sensorkonstruktion ermöglicht eine direkte Integration in den Prozess. Sensorlänge und Anschlussvariante können individuell an den Prozess angepasst werden, sodass der Polycondensationprogress can be continuously monitored. All measurements are automatically documented and available for subsequent analysis or audits. In this way, ecological responsibility is combined with economic efficiency.

Success stories and references:

Detailed case studies and customer references are available from our sales team. Feel free to contact us for specific application examples!

The main advantages at a glance

Consistent quality

Real-time monitoring prevents too strong or too weak cross-linking and ensures consistent product quality.

Cost savings

Less scrap, reduced raw material and energy consumption - with consistent product quality and process stability.

Highest efficiency

Real-time data enables faster decisions and optimized processes.

Robust sensors

Completely maintenance-free, drift-free, and cleaning-free sensors that require no consumables.

Frequently asked questions

SensoTech GmbH is a leading company in the field of process measurement technology, based in Barleben, near Magdeburg, Germany. We develop and produce innovative solutions for monitoring and optimizing industrial processes. Our specialization lies in the precise measurement of concentrations, densities, and other parameters in liquids - in real-time and directly during the process.

Since the speed of sound is influenced by temperature, all our LiquiSonic® sensors are equipped with high-precision temperature sensors. This allows the influence of temperature on the measurement to be directly compensated so it is not necessary to include additional temperature sensors during polymer resin production to be integrated.

Our sensors operate reliably in a temperature range from -40 °C to 200 °C and pressures up to 500 bar. Through various material options such as stainless steel, Hastelloy, or PFA coatings, aggressive media can also be measured. Explosion protection for Zone 1 and 2 is also available.

Yes, our sensors are designed for extreme conditions. In addition to the extended temperature and pressure range, we offer custom adaptations such as sensor lengths up to 3000 mm, special alloys for corrosive media, and various protection types, for example, optional explosion protection. Each sensor is individually configured according to your requirements configured.

Yes, by combining the speed of sound measurement with additional physical quantities (e.g., conductivity), multiple components gleichzeitig bestimmt werden. So lassen sich auch Zusatzstoffe bei der polymer resin production überwachen.

Unlike optical methods, which are influenced by color or turbidity, conductivity-based methods, which are sensitive to electrical conductivity, or density-based methods, which can be disturbed by temperature or gas bubbles, our ultrasound method independent of these influences. Unlike viscosity measurement, the process is also less sluggish, does not require sampling, and responds more sensitively to concentration fluctuations. The LiquiSonic® measurement technology also contains no moving parts or components that can wear out or be consumed. Therefore, after installation, the measuring system is completely maintenance-free and drift-free. The sensors offer digital signal transmission up to 1000 m and enable continuous inline measurement without sampling.

The system offers various digital interfaces (e.g., Profibus, Ethernet/IP, Foundation Fieldbus) as well as analog 4-20 mA outputs. The integration is seamless via standardized protocols.

There are no mechanical wear parts, seals, or optical windows that could be attacked or become clogged during inline measurement. Regular calibration is not required - the sensors remain stable for years. Unlike viscosity measurement, our ultrasonic method ultimately provides a more stable measurement and is also completely drift-free, cleaning-free, and maintenance-free.

The system delivers results in real-time. Based on these measurements, you receive a current measurement value every second. This fast response time enables effective process control and early detection of undesirable deviations during polycondensation.

Further applications

Blending of resins

When blending, different resins, additives, or solvents are mixed to achieve specific properties and a homogeneous composition.

Formaldehyde production

Formaldehyde production places high demands on process management, as even small deviations in methanol oxidation can have noticeable effects on efficiency and product quality.

Polymerization

Polymerization is a chemical process in which smaller molecules (monomers) join together to form larger molecules (polymers). This process is fundamental for the production of many plastics and other materials.