AdBlue® Production

The introduction of Selective Catalytic Reduction (SCR) catalysts has proven to be an efficient and cost-effective technique to reduce the content of nitrogen oxides (NOx) in the exhaust of diesel-powered vehicles. In this form of exhaust aftertreatment, the toxic nitrogen oxides are converted into nitrogen and water vapor in the catalyst by injecting the reagent AdBlue®, the toxic nitrogen oxides are converted into nitrogen and water vapor. The brand name AdBlue® stands for a synthetically produced 32.5% solution of high-purity urea in demineralized water.

The urea or urea solution has significantly higher purity than technical urea and must be carried in a separate tank in the vehicle. During vehicle operation, AdBlue® is pumped from this tank to the catalyst via a special pump and added to the exhaust stream there.

LiquiSonic® sound velocity measurement in urea

Application

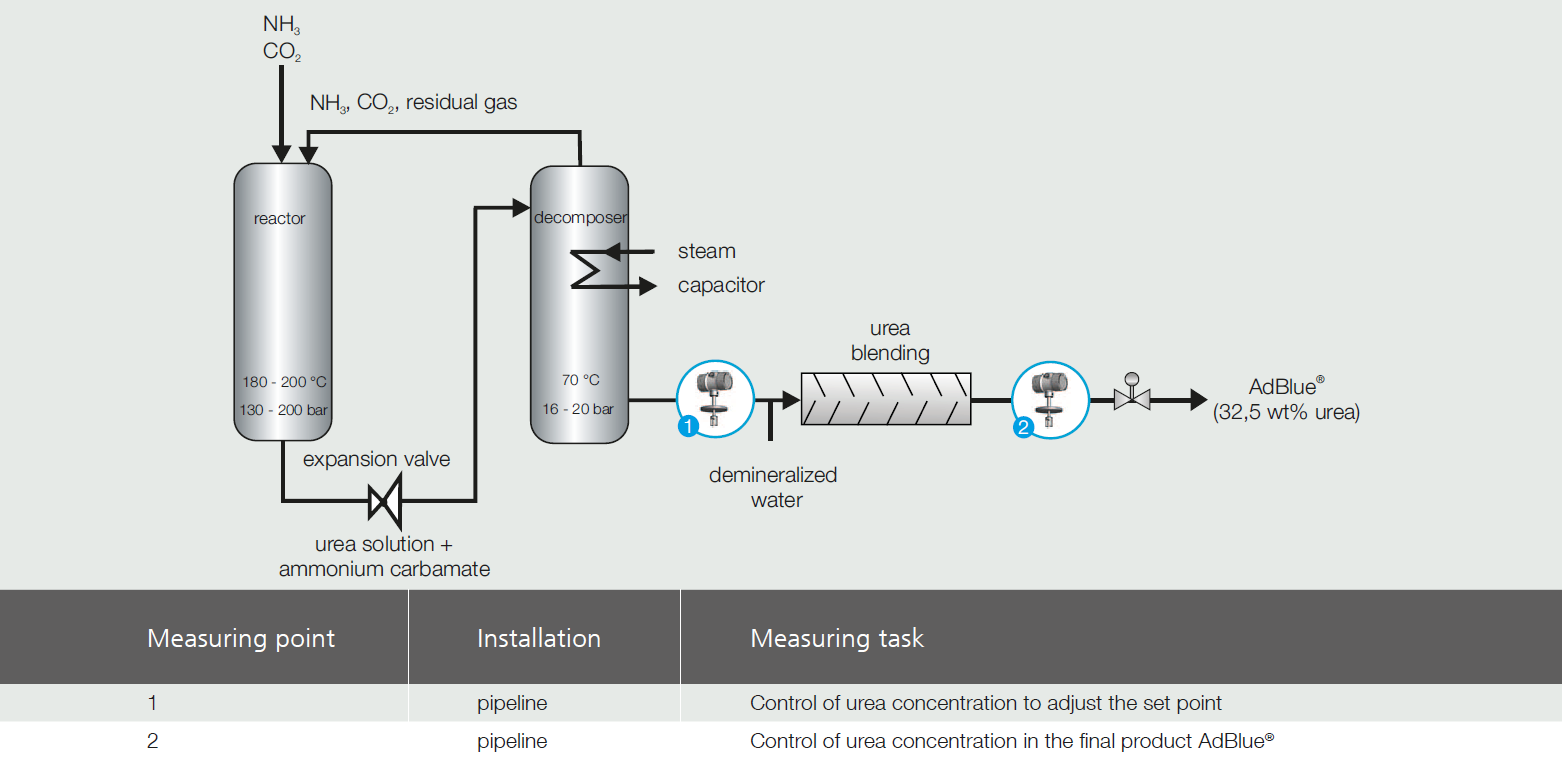

Urea is a synthetic product made from the starting material natural gas. Industrially, urea is produced from ammonia and carbon dioxide (urea synthesis). Under high pressure, the intermediate product ammonium carbamate is formed, which is then converted endothermically into urea at low pressure.

AdBlue® is produced in large plants as a blending product from urea. The high-purity synthetic urea is used to produce the 32.5% AdBlue®solution using demineralized water. Transport is carried out in insulated road tankers or plastic tank pallets (IBC).

As part of quality monitoring, an inline determination of the urea content in the end product AdBlue® is absolutely necessary. For this, the maintenance-free LiquiSonic® process measurement technology is ideally suited.

In addition, the risk of unwanted product crystallization is minimized.

Installation

The LiquiSonic® immersion sensors can be easily installed at the outlet of the decomposer or the mixer. The robust sensor design without moving parts ensures long process runtimes of the system.

The LiquiSonic® Controller 30 can be connected to up to 4 sensors. This makes it possible to monitor multiple measuring points simultaneously. With the help of the LiquiSonic® Lab Systems spot measurements of samples in the laboratory can also be carried out in seconds.

Typical measuring range:

Concentration range: 0 to 100 m%

Temperature range: -10 to 140 °C

Customer benefits

A high-precision concentration monitoring of the synthesized urea or AdBlue® is essential for quality control. LiquiSonic® determines the urea concentration inline, so that immediate action can be taken in the event of disturbances and deviations.

LiquiSonic® optimizes synthesis and blending:

- Production increase: at least 0.1%

Further LiquiSonic® Advantages at a glance:

- precise determination of the mixing ratio

- maintenance of consistent product quality

- seamless documentation

- integrated temperature measurement and warning limits signal under- and exceedances

- prevention of crystallization

Amortisation: < 6 Monate

AdBlue® is produced in large plants as a blending product from urea. A high-precision concentration monitoring of the synthesized urea or AdBlue® is essential for quality control. LiquiSonic® determines the urea concentration inline, so that immediate action can be taken in the event of disturbances and deviations.