LiquiSonic® Plato & Brix

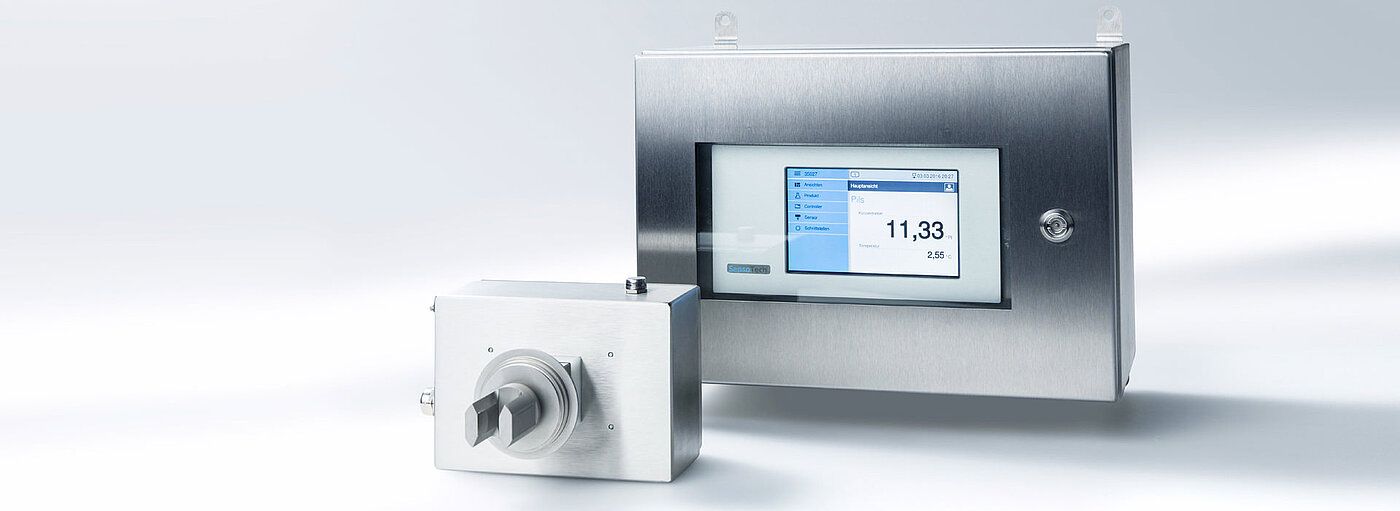

Depending on the application, the system consists of one or more intelligent sensors and a controller, which are connected via bus cables. Especially the combination of up to four sensors with only one controller at almost any distance between individual measuring points leads to comparatively low investment costs.

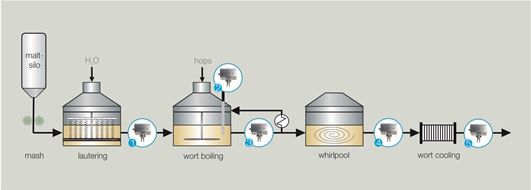

LiquiSonic® Plato & Brix can be used at various stages of the brewing process and beverage production to monitor product quality and minimize raw material and energy consumption

Applications in breweries

At the outlet of the lauter tun or mash filter, LiquiSonic® Plato is used to:

- control the course of lautering,

- determine the switching point to sparging water precisely,

- determine the average extract content (initial extract of the brew kettle) using an external flow meter (EXtrACt-Totalizer).

Download

User report on the use of LiquiSonic® Plato for process monitoring at the lauter tun of the Warsteiner Brewery, trade magazine 'Brauwelt'

Measure lauter wort concentration inline

In the wort kettle, LiquiSonic® Plato is used to:

- control the concentration course,

- ensure an exact determination of the concentration of the cast wort.

As a continuously measuring inline system, without the need for a bypass installation required by other measuring devices, LiquiSonic® Plato is easy to install and completely maintenance-free.

For internal boilers, a sensor is available that can be mounted directly in the boiler. A special design of the sensor keeps the influence of deposits very low. Additionally, the sensor in the internal boiler can be equipped with a cleaning head.

When used in an external boiler, the sensor is mounted directly in the circulation line between the wort pump and the heat exchanger.

In the wort cooler, LiquiSonic® Plato is used to:

- reliably separate wort and water in the event of rinsing processes,

- to check the original gravity before pitching the yeast.

The installation of LiquiSonic® Plato is hygienic and bypass-free in the wort flow.

Additionally, LiquiSonic® Plato monitors the cooling temperature through two integrated Pt1000 temperature sensors.

Download

User report on the use of LiquiSonic® for original gravity monitoring at the wort cooler of Colbitzer Heidebrauerei, trade magazine 'Beverages! Technology and Marketing'

Inline cold wort measurement for brewing process optimization

SensoTech is a long-standing supporting member of the German Brewmasters and Maltsters Association, Saxony regional group.

Do you have questions?

A measurement and analysis method, independent of conductivity, color, and transparency of the process liquid, long-term stable and highly precise:

This is LiquiSonic®.

The measurement system measures inline the concentration and density of liquids in industry and research. The measurement data is available online and updated every second. For our customers, we offer various versions tailored to the most diverse areas of application.