-

Measurement accuracy: ±0.05 wt%

-

Measuring range: 0 - max%

-

Temperature measurement range: 0 - 120 °C

-

High resistance

In a variety of industrial processes, environmentally harmful, corrosive, or toxic gases are used. To protect people and the environment, these are subject to strict regulations, particularly regarding the cleaning criteria that a gas scrubber must achieve.

In various (chemical) manufacturing processes, environmentally harmful or toxic gases are either raw materials or are produced as by-products.

Worldwide, gas scrubbers or wet scrubbers are used for the conversion of such gases to either eliminate the risk to people and the environment in an emergency (emergency gas scrubbers) or to clean process gases of undesirable gas components for further processing (for example: Benfield process gas scrubbers).

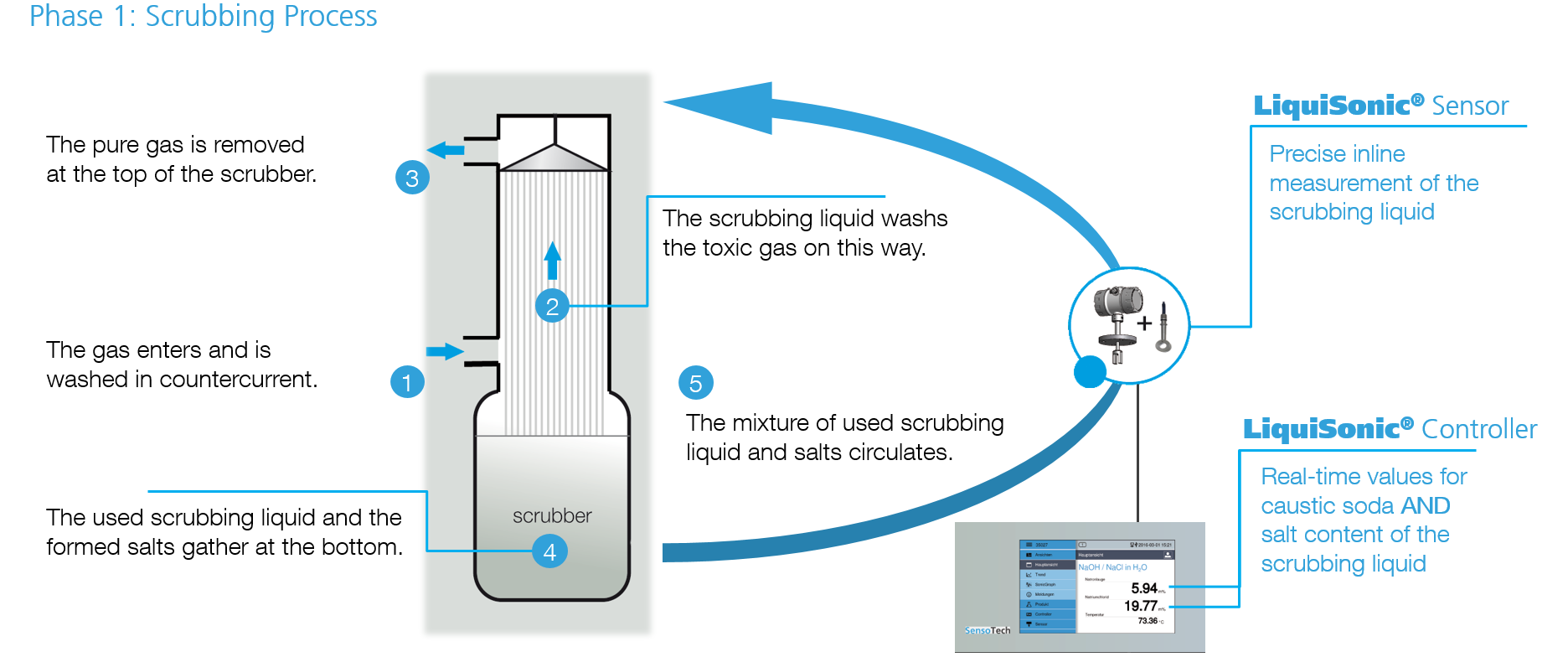

In this process, the gases to be cleaned are converted into harmless components with a washing liquid (e.g., caustic soda), so they no longer pose a risk to the environment or the process. These are mostly water and salts, which are easy to handle for further processing. Many gas scrubbers use caustic soda (NaOH) as the washing liquid. To achieve an optimal washing result, precise monitoring of caustic soda is necessary. LiquiSonic® Measuring systems are ideally suited for this monitoring.

Challenge in measuring the concentration or density of washing liquids

Achieve financial goals

- Avoid financial penalties

- Use resources efficiently

- Avoid costly processes

Protect employees

- Avoid unnecessary, dangerous process steps

- Avoid accidents, risks

- Make the process safe

Protect the environment

- Avoid environmental damage

- Reduce pollution

- Legal regulations

Ensuring the complete implementation of toxic components while efficiently using washing liquid often presents challenges for process engineers. The effectiveness of a gas scrubber depends on the precise dosing of the washing liquid (for example: caustic soda). Various measurement methods can be used to monitor the concentration, but they often provide insufficient results. There are several commonly used methods for monitoring the washing liquid, which in practice, however,have significant weaknesses:

Monitoring by pH value measurement

The service life of inline pH probes is severely limited due to the aggressive measurement conditions and causes regular maintenance effort. In addition, the user faces the challenge of interpreting the pH result, as there is no selective concentration display for washing liquid and salts. Thus, there is a risk that despite the low concentration of caustic soda, the measured pH value gives the user a false sense of security. Furthermore, the varying concentration of the resulting salts remains with this measurement variant.unknown. However, this is absolutely necessary, especially for isolating the salts.

Conductivity for the washing liquid control

Inline conductivity measuring devices have a similar problem: The physical quantity (conductivity) is influenced by both the washing liquid itself and the resulting salts. There is no way to consider both components separately. To accurately determine the concentrations, sampling and laboratory measurements, such as a time-consuming and costly titration, are usually necessary. Thus, the exact determination of the washing liquid concentration is only possible with great difficulty.

Determine density and concentration of washing liquids inline exactly

To enable an exact determination of the concentration of the washing liquid and the salts, two measurement variants must be combined. Only by using measuring devices that combine sound velocity and conductivity can multi-component mixtures like caustic soda and sodium chloride be safely and accurately analyzed.

The physical principles are ideally combined and the effect is used that sound velocity and conductivity react differently to a change in concentration levels in the process fluid. Thus, both concentrations can be determined exactly and the washing process can be optimally adjusted.

Customer benefits in gas scrubber monitoring

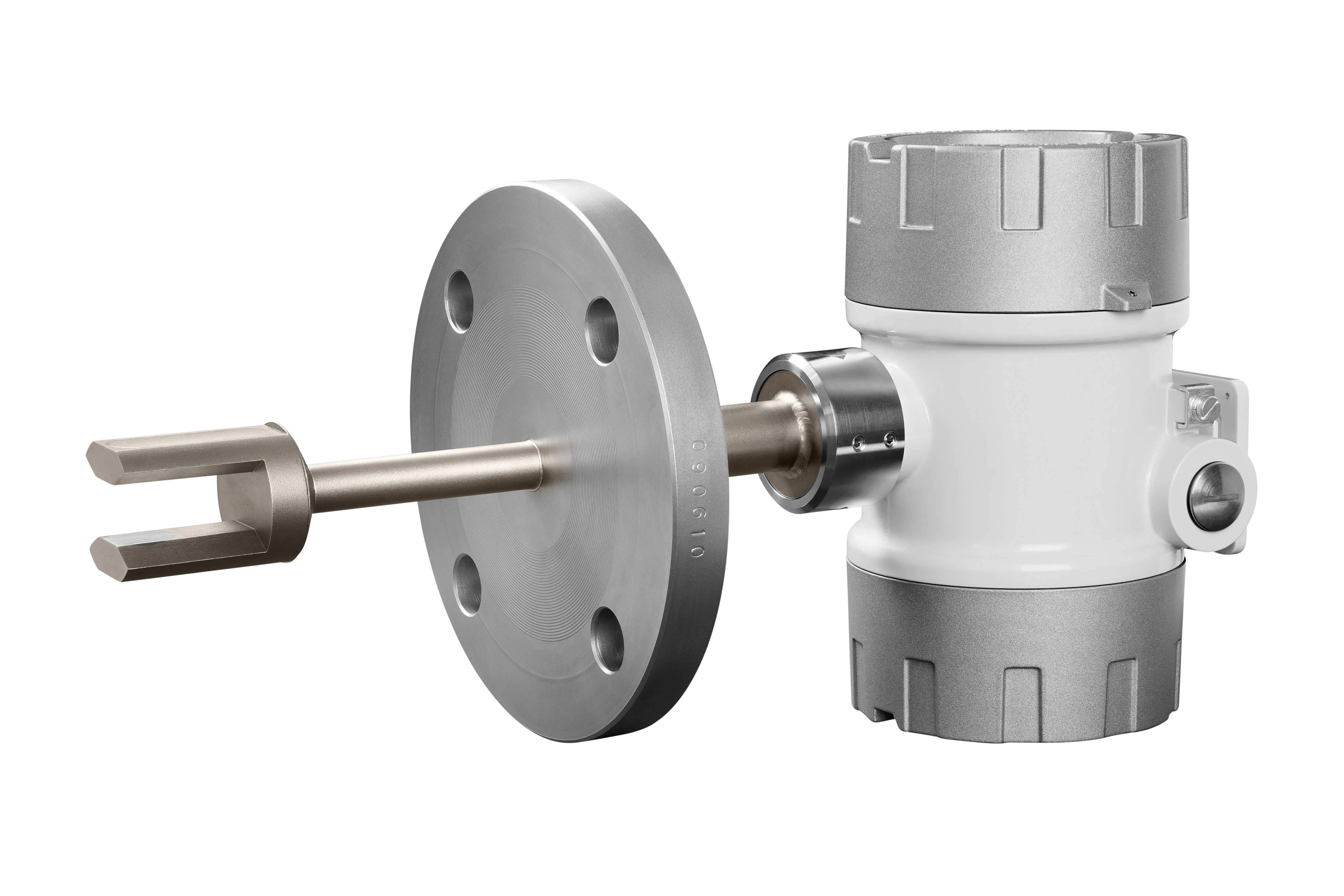

In the determination of the concentration of washing liquids, it convinces LiquiSonic® with its robust sensor construction, which makes wear parts and maintenance unnecessary. The measuring system is plug&play configured and convinces customers worldwide with its highly accurate measurement results along with long process uptime.

By accurately determining the concentrations, underdosages are actively avoided and process disturbances can be reacted to as quickly as possible. Through automatic and rapid replenishment of, for example, caustic soda, accidents, such as the release of chlorine gas, are prevented. The extensive diagnostic tools and data documentation are important tools for HSE management.

Through inline measurements with LiquiSonic® are sampling and time-consuming laboratory measurements replaced and material costs are reduced to a minimum.

LiquiSonic® in the gas scrubber process (example: phosgene gas scrubber)

In the production of many plastics, phosgene serves as a starting material. In the event of an emergency, the excess gas is directed into emergency gas scrubbers, where it is neutralized with caustic soda, producing the salts sodium chloride (NaCl) and sodium carbonate (Na2CO3) are formed. To ensure that all phosgene is absorbed, the concentration of caustic soda must be maintained at the level of maximum absorption.

For this purpose, the concentrations of caustic soda and the salt compounds must be strictly monitored. If the concentration of caustic soda is too low, the phosgene is no longer sufficiently absorbed, posing a safety-critical incident. Re-dosing is necessary.

In the case of too high a salt concentration in the solution, crystallization must be avoided. This requires precise inline measurement with real-time data.

Precise inline measurements as well as automatic re-dosing are easily achievable with LiquiSonic® feasible.

Installation of the measurement technology

The LiquiSonic® pipe and immersion sensors can be easily installed directly into the main line. An additional bypass is not necessary. A common installation site is in the circulation loop. The LiquiSonic® Controller 40 is connected to the LiquiSonic® sensor and the measurement unit for the second physical quantity (conductivity). The real-time measurement values can be transmitted to the process control system via various interfaces – such as Profibus DP or Modbus TCP.

Typical measurement range:

- Concentration range NaOH: 5 to 20 wt%

- Concentration range Na2CO3: 5 to 15 wt%

- Temperature range: 30 to 60 °C

Special gas scrubbers in detail

Benfield process gas scrubber | MDEA natural gas scrubber | Emergency gas scrubber | Phosgene gas scrubber

We solve your measurement task

Feel free to contact us. We support you in solving your individual measurement task.