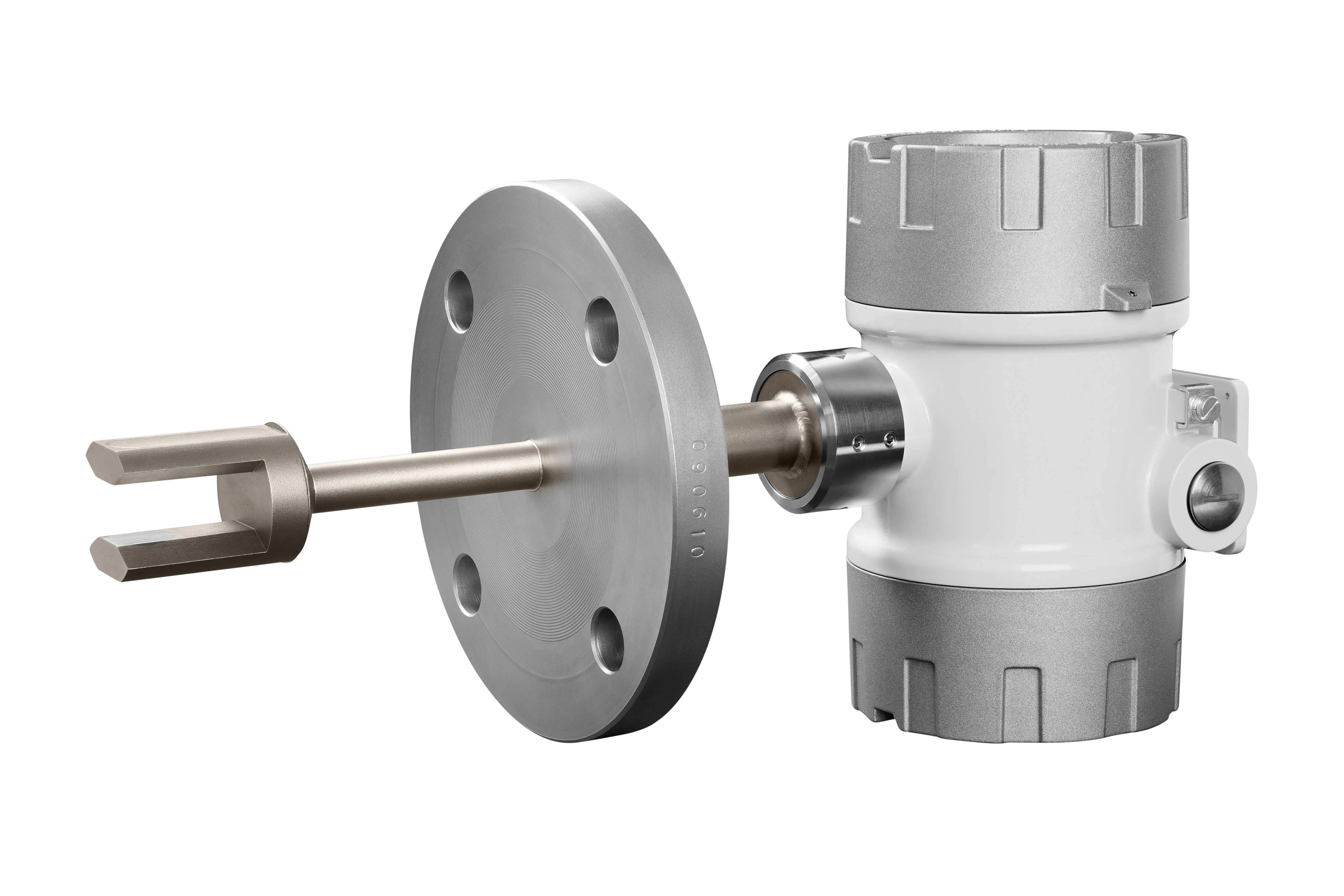

The sulfuric acid sensor

Measurement accuracy: 0.03 m%

Measurement range: 80 - 100 m% H2SO4

No cleaning necessary

Plug 'n' Play solution

Sulfuric acid is one of the most important basic chemicals. The constant demand is continuously increasing because the properties of sulfuric acid are useful for the production of many different products.

Some examples of important applications for measuring the concentration of sulfuric acid and oleum with the LiquiSonic® measurement systems:

- Sulfuric acid and oleum production

- Synthesis gas drying in the chemical and petrochemical industries

- Etching and pickling agents in the steel industry

- Ore leaching in mining

- Raw material for sulfate fertilizers

- Basic chemical for various chemical products

The two main production processes are the double contact process (double contact double absorption process (DCDA)) - a process in which a vanadium pentoxide (V2O5) catalyst is used to produce highly concentrated sulfuric acid and oleum - and the contact process (wet sulfuric acid process (WSA)), which removes sulfur from various process gases. The LiquiSonic® measurement system can be easily integrated into the various process stages of both processes mentioned above. The fast, robust sensor technology improves plant utilization, process safety, and product yield.

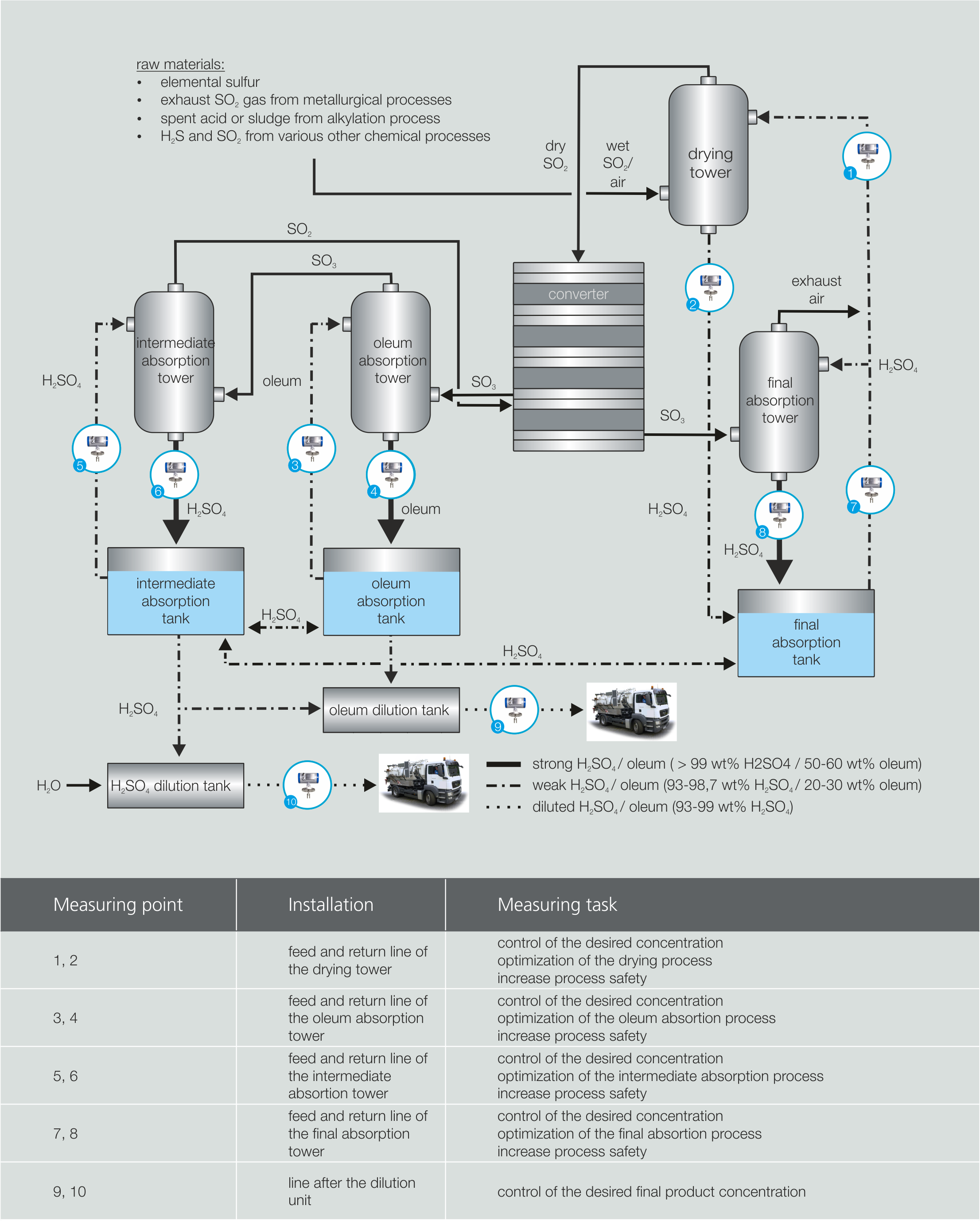

Double contact process

The double contact process (DCDA) uses a series of raw materials that synthesize into sulfur dioxide in various reactions. First, SO2-containing gas flows into the drying tower, where water is removed. Then the gas meets the catalyst in the converter, which oxidizes SO2 to SO3 oxidized.

2 SO2 + O2 → 2 SO3

Next, the SO3 enters the intermediate absorber. Although the absorption of sulfur trioxide in an aqueous solution is possible, such a highly exothermic reaction could attack and destroy the plant. The SO3 reacts with 98% sulfuric acid, forming highly concentrated acid.

SO3 to H2O → H2SO4

To reduce the environmental impact, the SO2-containing exhaust gases from the intermediate absorber flow again into the converter. There, they are used to prepare sulfur trioxide for processing into sulfuric acid in the final absorber. An intermediate product in the double contact process is oleum, which consists of 100% sulfuric acid enriched with SO3, is composed.

The possible applications include:

- Production of highly concentrated sulfuric acid

- Manufacture of caprolactam and nylon

- Nitration process in combination with nitric acid

Oleum is formed by the absorption of SO3 in an oleum absorption tower. The LiquiSonic® sensors provide excellent process control in oleum at concentrations between 20 – 30 wt% and 50 – 60 wt%. The sensors are ideally installed in the supply and return lines of the absorption towers and after the dilution unit.

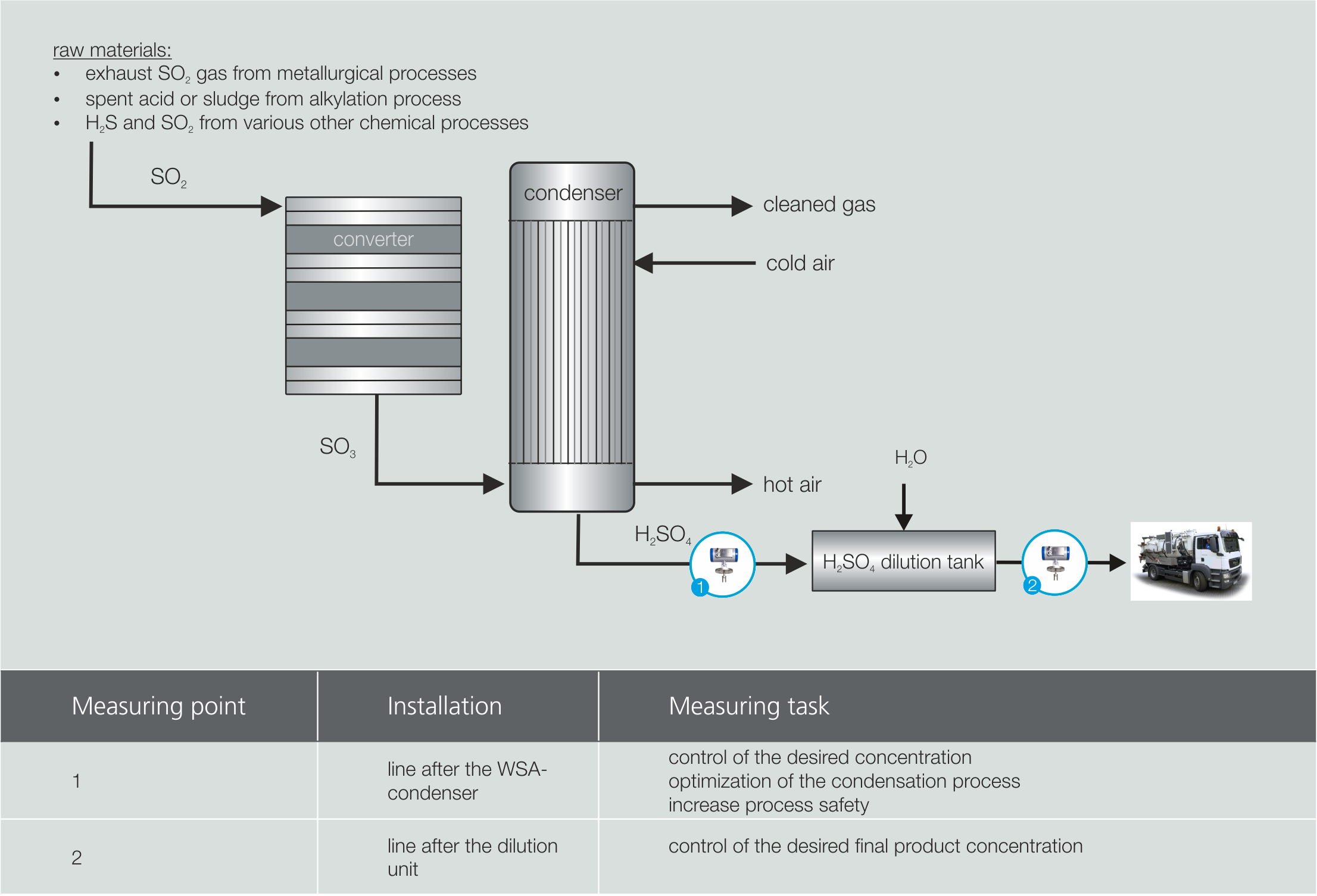

Contact process

Originally, the contact process (WSA) was developed to remove sulfur components from exhaust gases of various industrial manufacturing processes. In contrast to the double contact process, the water vapor remains in the resulting SO2. Thanks to a special vanadium-containing catalyst, the gas has no negative impact on the catalytic oxidation of SO2 to SO3 in the converter.

Finally, in the contact process, the sulfur trioxide enters the condenser, where water vapor condenses and SO3 into H2SO4 is converted. A concentration of 98 wt% is typical here. To measure the concentration directly in the line, installation of the LiquiSonic®sensors at the end of the condenser and the dilution unit is required.

Customer benefits

With the high sensitivity of the speed of sound in relation to the sulfuric acid concentration, the LiquiSonic® sensors achieve a very high accuracy of ± 0.03 wt%. The LiquiSonic® Measuring systems exceed the accuracy of conductivity and density, as in the concentration range of 80 – 100 wt%, as shown above, a clear sound signal is present and very precise measurements are possible. When lowering to a highly corrosive acid level below 95 wt%, the LiquiSonic® Measuring systems this critical situation and reduce the likelihood of heat exchangers or other components being damaged. This increases process control and safety. The inline LiquiSonic® Analyzers reduce manual laboratory measurements and save resources and material costs. Example of a typical laboratory titration budget for sulfuric acid measurements:

- Sampling time: 15 minutes

- Sampling frequency: 6 times a day

- Amortization usually under 12 months, besides laboratory costs other costs are eliminated (sampling points, process corrosion, plant shutdown)

Additional customer benefit of LiquiSonic® Measuring systems:

- simple, user-friendly installation (Plug & Play)

- excellent long-term stability

- one measuring device for all applications

- comprehensive diagnostic functions

- very accurate measurement results in all relevant concentration ranges

- improved process control and safety

We solve your measurement task

Feel free to contact us. We support you in solving your individual measurement task.