Typical separation processes for NaCl and KCl are:

- flotation

- electrostatic separation

- hot dissolution process

While NaCl exhibits good solubility in water regardless of temperature, the solubility of KCl increases with rising temperature. Thus, in large scale commercial plants, KCl is separated from NaCl in a hot dissolution process. The LiquiSonic® measuring technology provides an optimized quality control and productivity increase, especially trough fast process monitoring while hot dissolution process.

Application

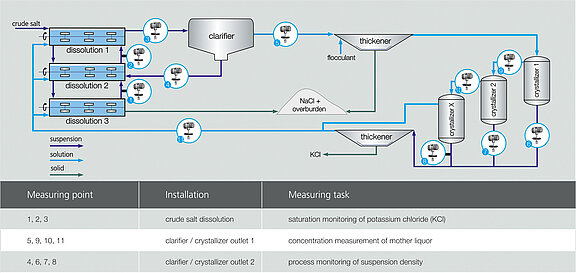

On account of the different dissolving properties of KCl and NaCl, the base material in the hot dissolution process is a saturated solution (mother liquor). After heating to ~ 120°C, crude salt (NaCl and KCl) is added. As the mother liquor is already saturated with NaCl, the NaCl does not pass into the solution and can be drawn off in the clarifier. In at least 3 successive crystallizers, the dissolved KCl is cooled down and precipitates. In the thickener, KCl is concentrated up to 97 wt% and separated from the mother liquor. The resulting saturated NaCl solution returned into the first process step as mother liquor.

The LiquiSonic® analyzer provides a precise inline concentration determination, based on sonic velocity measurement. Each process step (crude salt dissolution, clarification, crystallization, thickening) can be monitored, controlled and optimized in real-time. LiquiSonic®convinces customers with quality improvement and economic advantages, such as saving energy and materials.

Installation

The LiquiSonic® immersion sensor can easily be installed directly into the crystallizer or into pipelines and is well-equipped for measurements in solutions and suspensions.

Installation details:

- crystallizer: sensor length 300 - 500 mm

- pipeline (typically DN 300 - DN 800): sensor length 250 mm

- installation from below by partially filled pipes

By using the LiquiSonic® controller 30, up to four sensors can be connected, allowing the whole process to be monitored at different measuring points including:

- crude salt dissolution

- clarification

- crystallization unit

- KCl thickening

Typical measuring range:

concentration range: 1100 to 1600 g/l

temperature range: 70 to 110 °C (160°F to 230°F)

Customer value

The LiquiSonic® analyzer provides a precise inline concentration measurement with real-time monitoring. An automatic concentration-regulated process control prevents the plant from being „blocked“ (process control is too slow) and increases the process yield and productivity. The robust sensor construction and the optional spe-cial materials, like titanium, promote long process life.

Additional advantages are:

- optimum line control and reliable process data

- increasing the efficiency of clarifier and thickener

- drift free measurements over years

- early recognition of malfunctions in a matter of seconds

- reduced material and energy consumption and costs