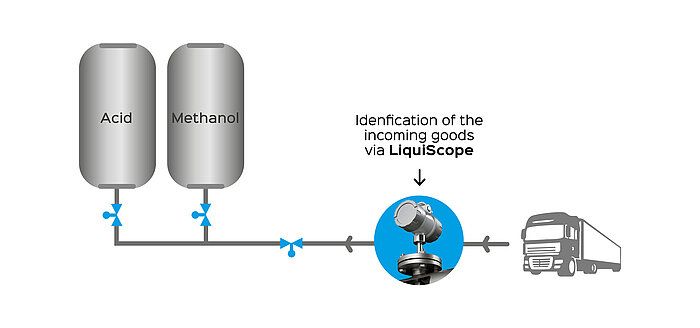

Liquid identification in tank farms // Incoming goods inspection

LiquiScope – Your solution to avoid misfillings and make processes safer

In our webinar, we will show you how LiquiScope enables inline liquid identification based on sound velocity measurement and how incorrect deliveries can be detected in real time. The webinar also offers the opportunity to submit individual questions directly to our experts, especially when specific applications still need to be examined or evaluated. Register now for free!

Why LiquiScope?

In Tank farms, Tank terminals and in the hazardous material storage every correct assignment of liquids counts. Even small mix-ups can cause costly damage and pose dangerous risks to people and the environment. With LiquiScope you get a high-precision system for liquid identification, which is based on sound velocity measurement based:

- Prevent misfilling: Detect early whether the delivered liquid is correct.

- Process safety: Minimize risks and meet the requirements for professional risk management in tank farms.

- Save time & costs: Avoid cumbersome chemical analyses and manual sampling. LiquiScope delivers results in real-time.

- Seamless integration: Integrate our automated liquid detection into your existing control system and keep all processes in view.

This is how LiquiScope works

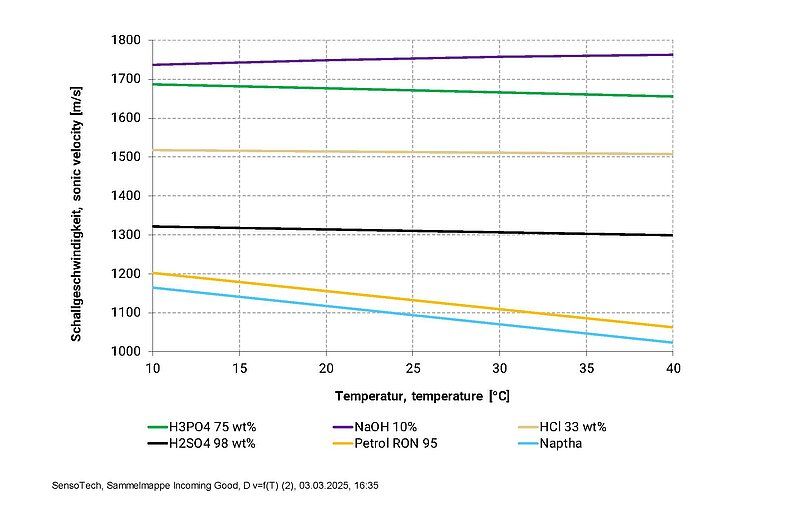

- Measurement of sound velocity

A sensor continuously records the sound velocity of the flowing liquid during operation. - Comparison with reference data

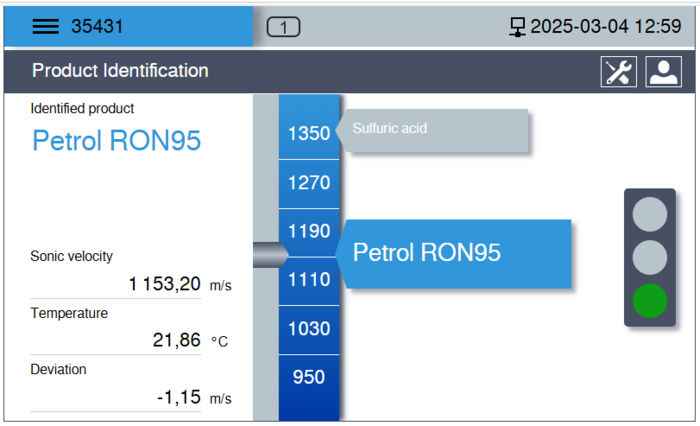

The measured values are automatically compared with stored reference values – similar to a "digital fingerprint". - Identification & warning

If the values deviate from the expected medium, you will receive a warning message in a short time to prevent unwanted storage. - Real-time data collection

Whether on-site at the display or centrally in your control system: You immediately see which medium is present – for a maximum of product safety.

Simple procedure for tanks with only one expected liquid

In many Tank farms or processes, there is only one defined liquid in a tank. LiquiScope allows for a particularly reduced setup, where only the measured sound velocity matches the expected liquid:

- Target/actual comparison: A certain target sound velocity is stored.

- Deviation: If the measured value deviates significantly from the tolerance, it is clear that another medium is present and the introduced product must be stopped.

- Quick reaction: The filling is interrupted before there is a misfill in the tank.

This procedure requires no complex analytics or additional sensors, thus reducing costs and effort, while still providing a high level of safety.

Your benefits at a glance

- Increase safety in tank farms

LiquiScope reduces risks and hazards and increases operational safety – a crucial factor for tank farm operation and tank farm management. - quality assurance of media

With the automated liquid detection ensure that only the correct liquid is delivered. - Process control in pipelines

Monitor liquid flows in real-time and ensure reliable inventory control. - Compatible with existing systems

The integration into your existing plant technology or control systems is straightforward. This way, you can keep all data in view within one system. - Sustainably save costs

With LiquiScope, you avoid damage due to misfills and simultaneously reduce the effort for manual checks and laboratory analyses.

Areas of application

- Tank farm & tank terminal: Prevent misfills and ensure reliable Inventory management.

- Incoming goods inspectionCheck immediately if the delivered medium matches your order.

- Pipeline monitoringMaintain control over the medium in your pipelines before it reaches the storage.

- Process industryFood, chemical, cosmetic or pharmaceutical – everywhere a seamless Quality assurance is indispensable

Contact us – we will find the right solution for you!

Whether you want comprehensive Tank monitoring or a simplified procedure for individual tanks: We adapt LiquiScope to your requirements.

Would you like to learn more or receive a personal offer?

Fill out our contact form or call us. We are happy to provide individual advice and find the right concept for your liquid management.

LiquiScope – the intelligent liquid detection for your tank farm operation and your Incoming goods inspection. Create maximum Process safety and reliability in all areas!