Monitoring incoming goods and product quality is very important for a lot of processes. These measurements are often done at various stages in the production process. SensoTech’s mobile LiquiSonic® Lab system is the perfect solution to get fast, precise and reliable measurements.

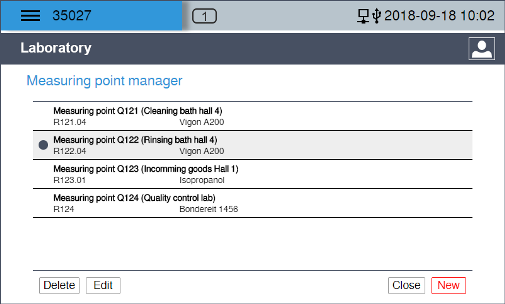

The newly developed and user-friendly designed “Measuring Point Management” gives users the opportunity to clearly define each measuring point in the process, e.g. label, room, specific medium, in advance.

Additionally, the LiquiSonic® Lab System creates detailed datasets every time the user saves a measuring, which simplifies the subsequent analysis tremendously. The controller menu provides an overview of historical data for every measuring point. Deviations e.g. in quality are well comprehensible at any time. These data can be easily transferred to the process control system via ethernet or USB devices. Every recording generates an entry with date, time and the name of the measuring point in the event logbook.

Prospective, the LiquiSonic® Lab system optionally comes with a scanner for an easier handling. After scanning, e.g. a QR code, the controller will automatically switch to the correct measuring point and the measurement can be taken right away.

Visit SensoTech at parts2clean 2018 (hall 5, booth A36) and get to know all information about the innovative integrated “Measuring Point Manager”.