Chlorine gas drying

The LiquiSonic® Measurement technology is used in various processes and production streams to detect concentration and thus optimize quality and productivity. Another application field of the measurement technology is in the downstream process of chlorine gas drying. The chlorine gas must be freed from its water content, otherwise, it leads to the formation of chlorine hydrate, and the corrosion behavior continuously increases at a moisture content over 30 ppm.

Advantage of sound velocity over conductivity and density

Application

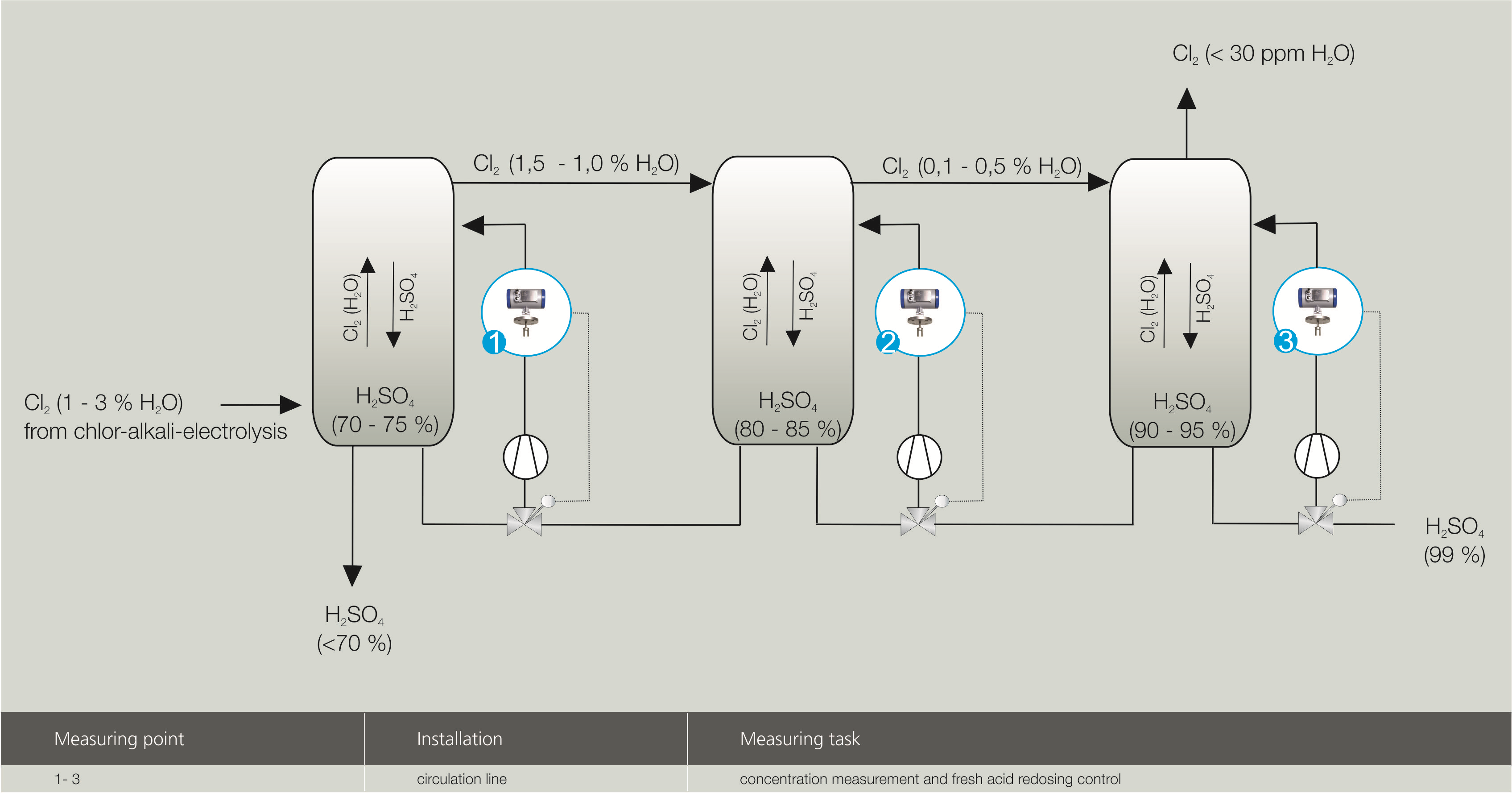

The process of chlorine gas drying is based on the passage of the gas through the absorption towers (scrubbers), in which the water content in the chlorine gas is chemically bound by concentrated sulfuric acid (H2SO4) is chemically bound. Sulfuric acid is used as a drying agent because it has hygroscopic properties, meaning a strong attraction to water.

The moist chlorine passes through several scrubbers during drying, with the concentration of H2SO4 increasing from scrubber to scrubber. The higher the H2SO4- concentration, the higher the absorption efficiency (or drying effectiveness). Accordingly, in the last scrubber, there is a highly concentrated H2SO4 (90 – 96%) because the water content in the chlorine gas is reduced to less than 30 ppm. By removing the water content in the chlorine gas, the sulfuric acid in the scrubbers is diluted. The diluted H2SO4 is then passed into the previous scrubbers with lower H2SO4 concentrations.

The effectiveness of this drying process significantly influences the productivity and quality of the gas. Therefore, reliable measurement of the sulfuric acid concentration is of particular importance.

The measurement system LiquiSonic® 30 allows for the measurement of sulfuric acid concentration using sound velocity as well as high-precision temperature measurement. Through inline concentration analysis with LiquiSonic® sensors the process of chlorine gas drying can be analyzed around the clock, guaranteeing an exact real-time analysis of the sulfuric acid concentration. Through precise monitoring of the sulfuric acid concentration in the respective absorption towers using the measurement system LiquiSonic® 30 the desired effectiveness of chlorine gas drying is ensured at all times.

Installation

The installation of the sensors takes place in the DN80 transport lines of the absorption towers.

Concentration range H2SO4: 70 wt% to 100 wt%

Temperature range H2SO4: 20 °C to 60 °C

When used in sulfuric acid, the liquid-contacting parts of the sensor are made of HC2000.

Customer benefits

LiquiSonic®enables a reduction in laboratory costs by eliminating manual sampling:

- Time required: 3 hours per day

- Payback period: approx. 7 months

To protect plant components from corrosion, the water content in the chlorine gas must be less than 30 ppm. Continuous monitoring of the sulfuric acid in the respective scrubber ensures the required purity of the chlorine gas (less than 30 ppm H20) can be ensured.

Chlorine is one of the most important basic chemicals and is one of the most produced chemicals worldwide. Chlorine is produced on a large scale by the chlor-alkali electrolysis. The starting material for electrolysis is an aqueous sodium chloride solution (NaCl). By-products are hydrogen and caustic soda, which are also recycled in large quantities by the chemical industry. In the chlor-alkali process, different electrolytic methods are used, with the diaphragm, membrane, or amalgam process being themost common production technologies.