Crystallization monitoring

The device is based on the highly precise measurement of absolute sound velocity and process temperature, allowing the tracking of processes and complex reactions.

The benefits for the user are:

- optimal plant control through online information about the process state

- maximum efficiency of the processes

- increase in product quality

- reduction of complex laboratory measurements

- savings on energy and material costs

- improved plant utilization

- reproducible process control through 'fingerprint' function

The use of state-of-the-art digital signal processing technologies guarantees extremely accurate and interference-free measurement of absolute sound velocity and concentration. Additionally, integrated temperature sensors, sophisticated sensor design, and know-how developed in countless measurement series and many applications ensure high system reliability with long service life.

The advantages of the measurement method are:

- absolute sound velocity as a distinct and traceable physical quantity

- independent of color, conductivity, and transparency of the process fluid

- installation directly in pipelines and containers

- robust sensor design in completely metallic construction without seals or moving parts

- maintenance-free

- corrosion resistance through the use of special materials

- use at temperatures up to 200 °C

- high, drift-free measurement accuracy even with a high gas bubble content

- connection of up to four sensors per controller

- forwarding of measurement results via fieldbus (Profibus DP, Modbus), analog outputs, serial interface, or Ethernet

Innovative sensor technology

SensoTech is the specialist for the analysis and optimization of process engineering processes in liquids. Since its founding in 1990, we have developed into the leading company for measuring devices for inline determination of concentrations in liquids. Our analysis systems set the trend worldwide.

Innovative engineering made in Germany, based on the principle of measuring absolute sound velocity in the ongoing process. A method that we have perfected into a highly precise and exceptionally user-friendly sensor technology.

Typical applications besides concentration and density measurement are phase detection or tracking of complex reactions such as polymerization and crystallization. Our LiquiSonic® Measurement and analysis systems ensure optimal product quality, maximum plant safety, or reduce costs through efficient resource management in various industries, such as the chemical and pharmaceutical industry, steel industry, food technology, mechanical and plant engineering, automotive technology, and others.

We want you to fully exploit the potential of your production facilities at all times. Systems from SensoTech deliver highly accurate measurement results even under difficult process conditions, precisely and reproducibly. And this inline and without safety-critical sample extractions, immediately available for your automation system. All system parameters can also be adjusted with powerful configuration tools, so you can react immediately and easily to changes.

We offer excellent, mature technology to improve your manufacturing processes and are a partner for demanding, often unexpected solutions in your industry, for your applications - no matter how specific they may be. When it comes to liquids, we set the standards.

Basics of crystallization

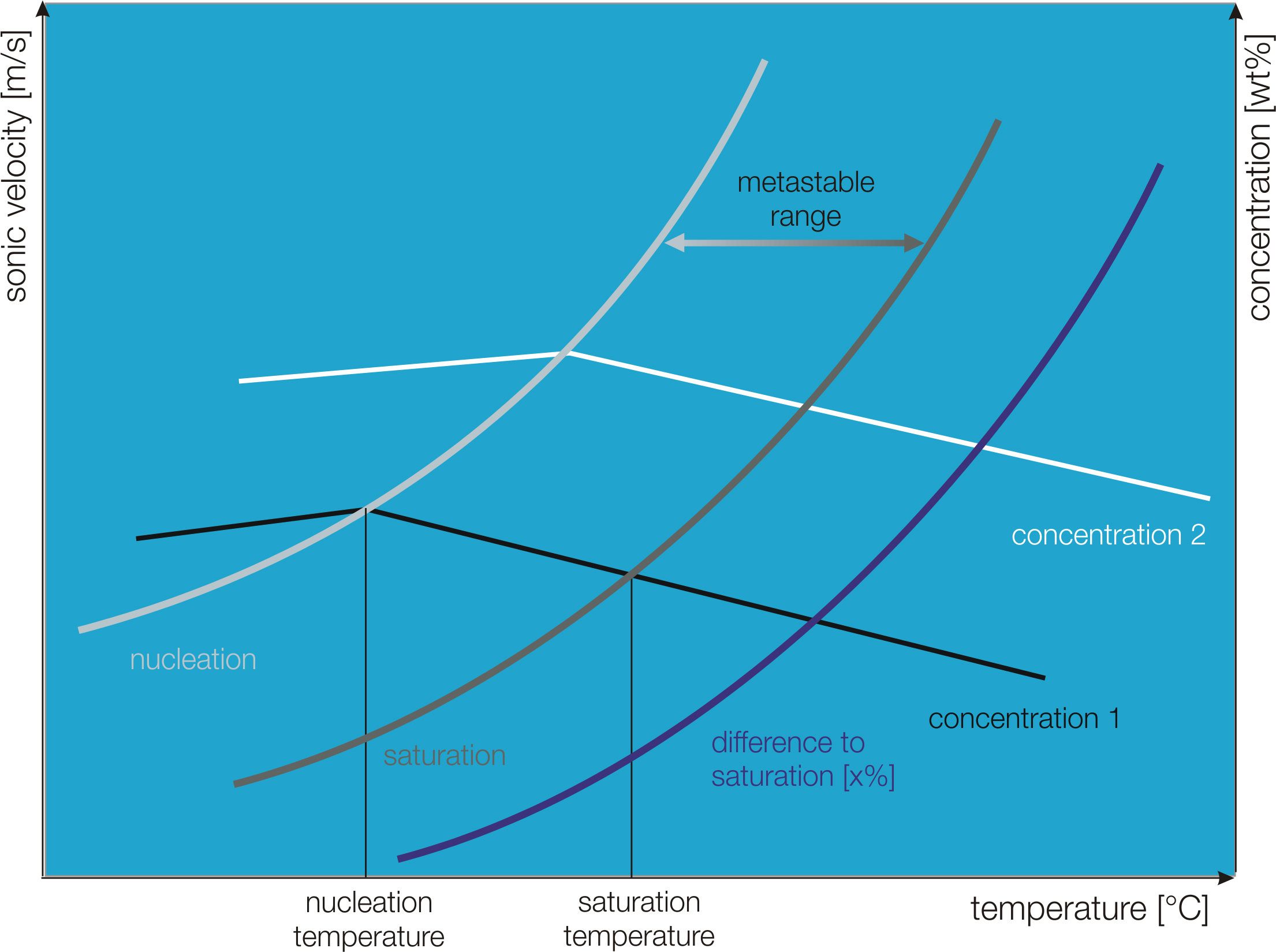

To determine crystallization parameters and control crystallization processes, sound velocity measurement is used. With this measurement method, the nucleation and saturation point, and thus the metastable region, can be determined. In the process, during crystallization, the difference to saturation (degree of saturation), the degree of supersaturation, or the crystal content can be measured and used as a control variable for targeted influence on crystallization.

If a solid substance is dissolved in a liquid, the liquid can absorb it up to a certain concentration. If more of the substance is added to the liquid, it will no longer be dissolved because the solution is saturated. As a result, the substance remains in solid form. This 'maximum' concentration of a solution is referred to as the solubility or saturation concentration. The saturation concentration depends on the temperature of the liquid. The temperature at which the solution becomes saturated is calledsaturation temperature. If the temperature is increased, more substance can be dissolved (except in the case of negative solubility). Accordingly, the saturation concentration increases.

If the concentration is less than the saturation concentration, it is called an unsaturated solution. If the temperature of an unsaturated solution is reduced, it can be cooled to a lower value than the saturation temperature in many solutions without the solid substance crystallizing. The solution is then supersaturated. If it is further cooled, spontaneous nucleation or crystal formation (nucleation) occurs at a certain temperature, the nucleation temperature.

If the suspension is then heated, the crystals dissolve again. When the saturation temperature is reached, all the crystals are finally dissolved. The saturation temperature is usually higher than the nucleation temperature.

The supersaturated area between the saturation temperature and the nucleation temperature is called the metastable area. By using LiquiSonic® systems in crystallization processes, the following advantages arise for the user:

- improved plant utilization through

- continuous display of under- and supersaturation

- control of the process via the crystallization parameters

- avoidance of spontaneous nucleation

- energy savings through

- quick control of the desired seeding time

- continuous determination of the crystal content

- optimal approach to the process endpoint

- raw material savings through

- optimal adjustment of the desired product quality

- reproducible approach to the seeding time

processes

Through the continuous measurement of the sound velocity using LiquiSonic® measurement technology the crystallization processes can be monitored both in continuous and batch processes. In case of disturbances or deviations from the ideal process course, immediate action can be taken to achieve the desired product quality. The following figure includes the evaluation of three different batch runs with regard to temperature, sound velocity, and standard deviation.

In most cases, a preliminary investigation determines the characteristic process band, which leads to an optimal reaction course and thus to the desired properties of the final product.

Minor deviations from the ideal process are made available to the operator or process control through typical analog or digital interfaces, for example, to steer the crystallization back to the ideal course via temperature control.

Statistical evaluation of multiple sound measurements per second

Applications

Crystallization parameters

For recording the parameters relevant to the process, the speed of sound and temperature are measured during the cooling and heating of a solution. By plotting the speed of sound as a function of temperature, important crystallization parameters such as saturation temperature, nucleation temperature, and position in the metastable region can be directly determined. The following figure describes the crystallization characteristics of 42.6 wt% ammonium sulfate during heating and cooling at differenttemperature ramps.

The illustration explains the determination of crystallization parameters: If the solution is slowly cooled, the speed of sound changes with a certain temperature coefficient. From a certain temperature, the speed of sound changes more strongly due to crystal formation and the reduction of supersaturation. This temperature represents the nucleation temperature. When the solution is then reheated, it shows a different speed of sound profile than during cooling. At the saturation temperatureboth curves meet again.

Consequently, the metastable region and the solubility curve can be determined via the speed of sound. The metastable region depends on the chemical composition of the solution and the cooling rate. The metastable region of any given solution can be determined using the speed of sound as a function of temperature.

Crystallization process in ammonium sulfate at a concentration of 42.6 wt%

Degree of saturation

The online measurement of the degree of saturation is based on the variable saturation concentrations at different temperatures. The following figure exemplarily shows the saturation behavior of a large-scale crystallization process.

The current concentration is determined by measuring the speed of sound and temperature. Furthermore, the difference to saturation (degree of saturation) can be made available to the downstream process control if required. With this information, it is possible to optimally drive to the saturation curve via the process temperature. This leads to time and energy savings. Even with fluctuations in concentration in the initial solution, the process is reproducibly controlled.

Spontaneous nucleation finally occurs on the nucleation line. The area between saturation and nucleation is referred to as the metastable (supersaturated) region. Supersaturation serves as an indicator for the perfect seeding time in controlled nucleation.

Sättigung in Abhängigkeit von Konzentration, Temperatur & Schallgeschwindigkeit

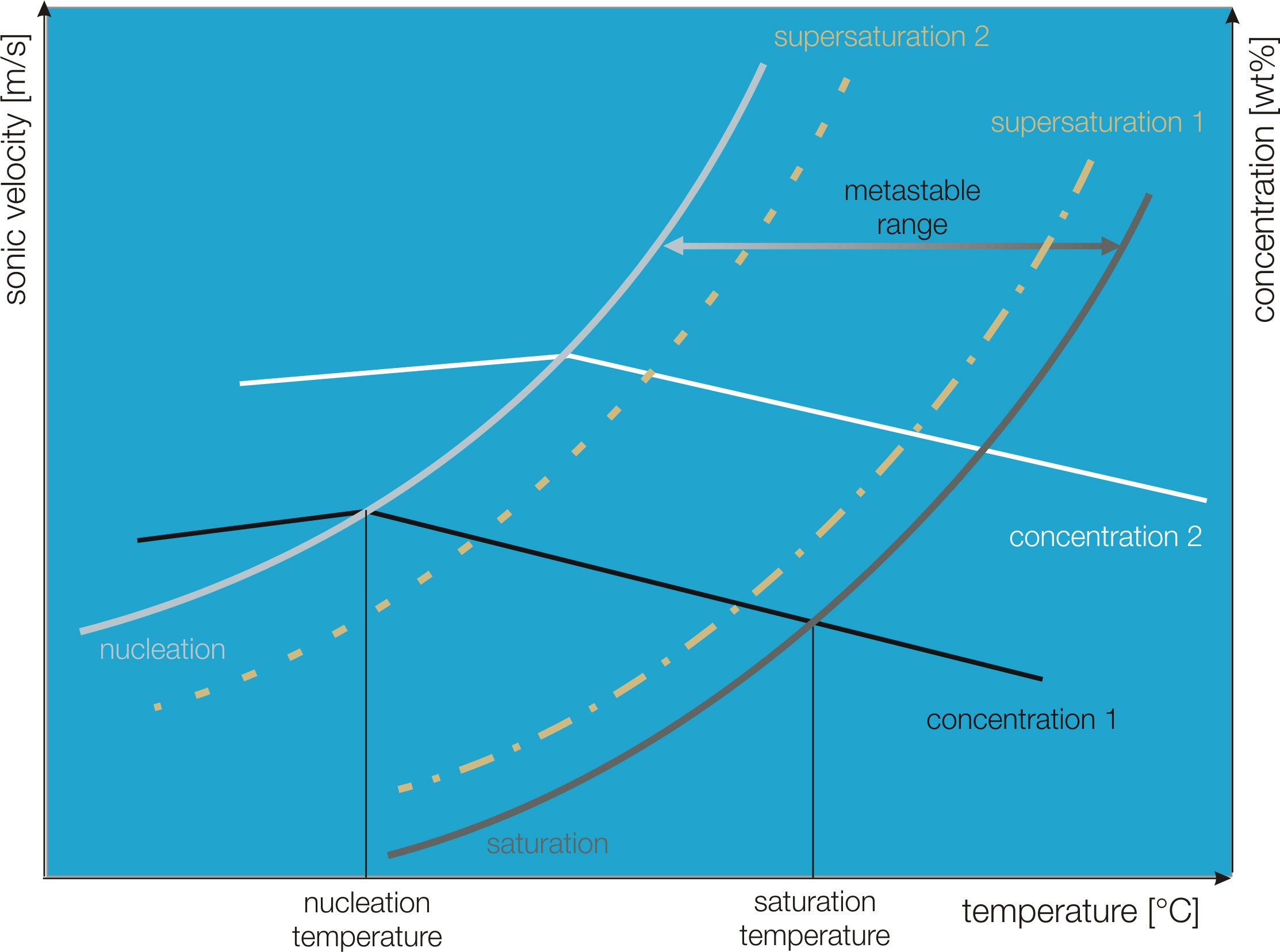

Supersaturation

The degree of supersaturation can also be determined using the speed of sound as a function of temperature. As can be seen in the following figure, the degree of supersaturation reflects a point in the metastable region. The closer this point is to the nucleation line, the greater the degree of supersaturation.

As the upper limit of the metastable region (supersaturation 2) is approached, the risk of spontaneous nucleation of an overly fine end product increases. If crystallization takes place too close to the saturation curve (supersaturation 1), there are only very few and large crystals.

During crystallization, the supersaturation of the solution changes due to crystal growth. With growth, the degree of supersaturation is reduced. If the temperature of the mother liquor decreases or the solvent evaporates, supersaturation increases again.

By measuring the sound velocity and temperature in the mother liquor during crystallization, the crystallization process can be optimally conducted in the metastable region. This allows direct influence on growth and thus on the morphology of the crystals.

Supersaturation as a function of concentration, temperature & sound velocity

Supersaturation reduction and crystal growth kinetics

The degree of supersaturation reduction during crystallization can be represented as a function of time (supersaturation reduction curve). The following figure shows different growth kinetics detected by the decrease in sound velocity and supersaturation.

It is shown that the temporal course of sound velocity during crystallization exhibits the same behavior as the known supersaturation reduction curves. In the figure, the supersaturation reduction curve calculated from the sound velocity is compared with the chemical analysis according to Tavare and Chivate.

From the supersaturation reduction curve, the crystal growth kinetics can be determined. This indicates how fast the crystals grow in the mother liquor and is thus an important parameter for the design and dimensioning of crystallizers.

The relationship between supersaturation and sound velocity allows the supersaturation reduction curve to be measured directly.

Supersaturation reduction as a function of time

Crystal content

Each suspension is characterized by a course of sound velocity dependent on temperature and concentration. The corresponding characteristic fields are also stored in LiquiSonic® System stored, which thus enables the direct inline measurement of the solid concentration or crystal content or TS content.

In continuous crystallization processes, monitoring and control of separation is possible by determining the crystal content. In batch processes, the endpoint of crystallization and crystal growth can be determined and monitored.

Dependence of the speed of sound on the concentration of NaCl in water, 25 °C

Quality and Service

Enthusiasm for technological progress is our driving force to help shape the market of tomorrow. You, our customers, are at the center of this. We are committed to providing you with top performance.

In close collaboration with you, we pursue the path of innovation by developing the right solution for your challenging measurement task or by making individual system adjustments. The increasing complexity of application-specific requirements makes a comprehensive understanding of relationships and interactions essential.

Creative research is another fundamental pillar of our company. The specialists in our research and development team contribute valuable work to optimize product properties, such as testing innovative sensor designs and materials or the well-thought-out functionality of electronic, hardware, and software components.

Our SensoTech quality management accepts only top performance in production as well. We have been ISO 9001 certified since 1995. All device components undergo various testing procedures at different production stages; the systems are subjected to a burn-in procedure in-house. Our maxim: highest functionality, reliability, and safety.

All this is only possible through the commitment and pronounced quality awareness of our employees. We owe our success to their excellent expertise and motivation. Together, with passion and conviction, we work with unmatched excellence.

We maintain relationships with our customers. They are based on partnership and grown trust. Since our devices are maintenance-free, we can fully focus on your concerns in terms of service and actively support you through professional advice, convenient in-house installation, and customer training. In the concept phase, we analyze your situational conditions directly on-site and, if necessary, carry out test measurements. Our measuring devices are capable of achieving the highest accuracy even under unfavorable conditions.and reliability. Even after installation: We are there for you, our response times are short – thanks to remote access options specifically tailored to you.

As part of our international collaborations, we form a globally networked team for our customers, ensuring optimal advice and service across borders. Therefore, we value effective knowledge and qualification management. Our numerous international representations in all major geographic markets of the world can rely on the expertise within the company and continuously update their competence in application- and practice-oriented training programs. Proximity to thecustomer, around the globe: in addition to extensive industry experience, a key factor for our successful presence worldwide.