Solvent distillation

Even fresh solvents sometimes do not meet the requirements for the desired purity or target concentration and can also be finely cleaned and concentrated in solvent processing plants. There are various distillation methods that deliver different results, e.g., packed columns with reflux automation for particularly high separation efficiency or vacuum distillation for sensitive media. Typical solvents are acetone, ethanol, toluene, n-hexane, or ethyl acetate. There is a wide range ofdistillable solvents.

Speed of sound measurement during solvent distillation

Application

It is important that the recovered solvents match the quality of the original substances to ensure consistent product quality in the subsequent process. Ideally, recyclates are produced that are hardly distinguishable from fresh material. The clean distillate can be directly returned to the production process.

Monitoring the distillate concentration during processing is an important factor to minimize processing costs and increase solvent availability. The disposal of solvents (or other chemicals) contaminated in the production process is a costly procedure. Solvents are usually easily and economically processed and recovered in-house. This saves costs through reduced purchase of fresh goods, minimization of storage, and less handling effort.and significantly lower disposal and transport costs.

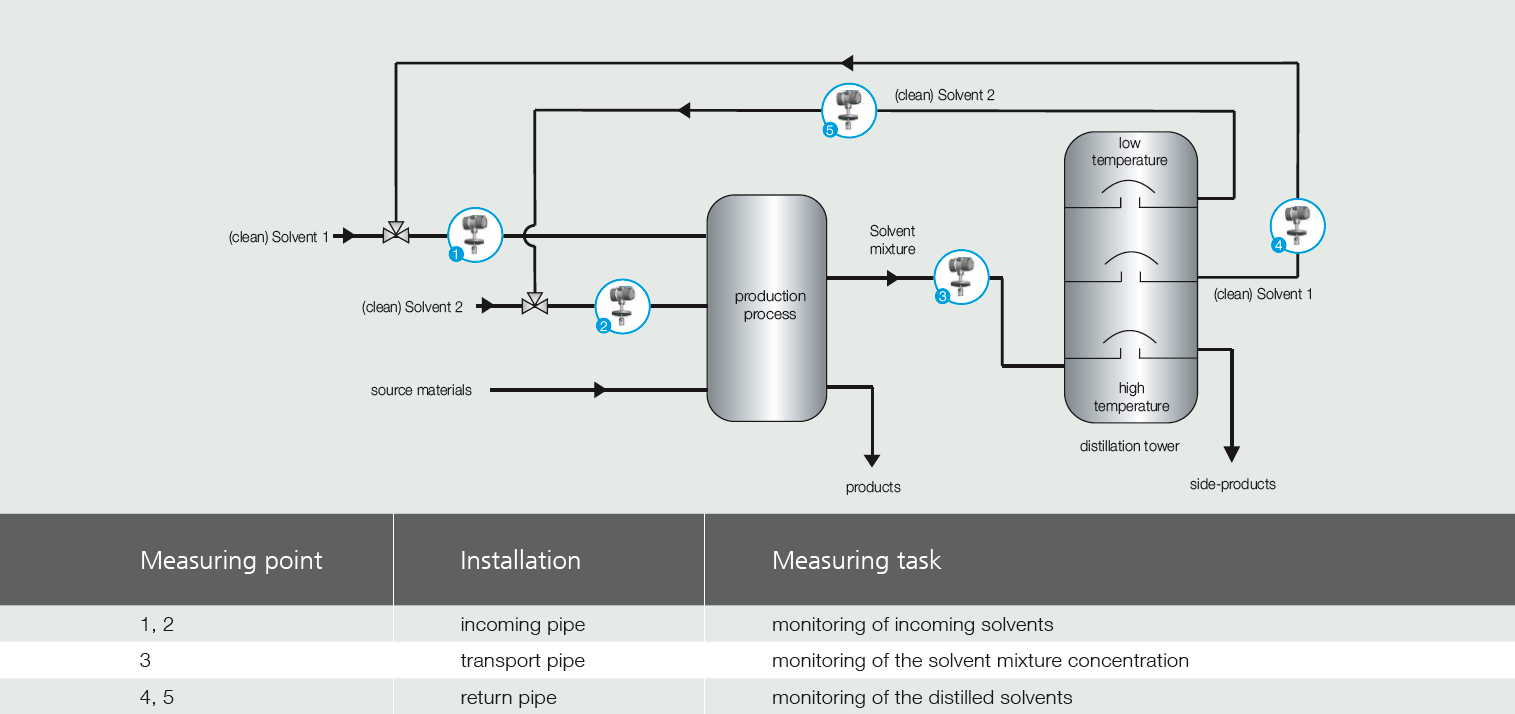

Installation

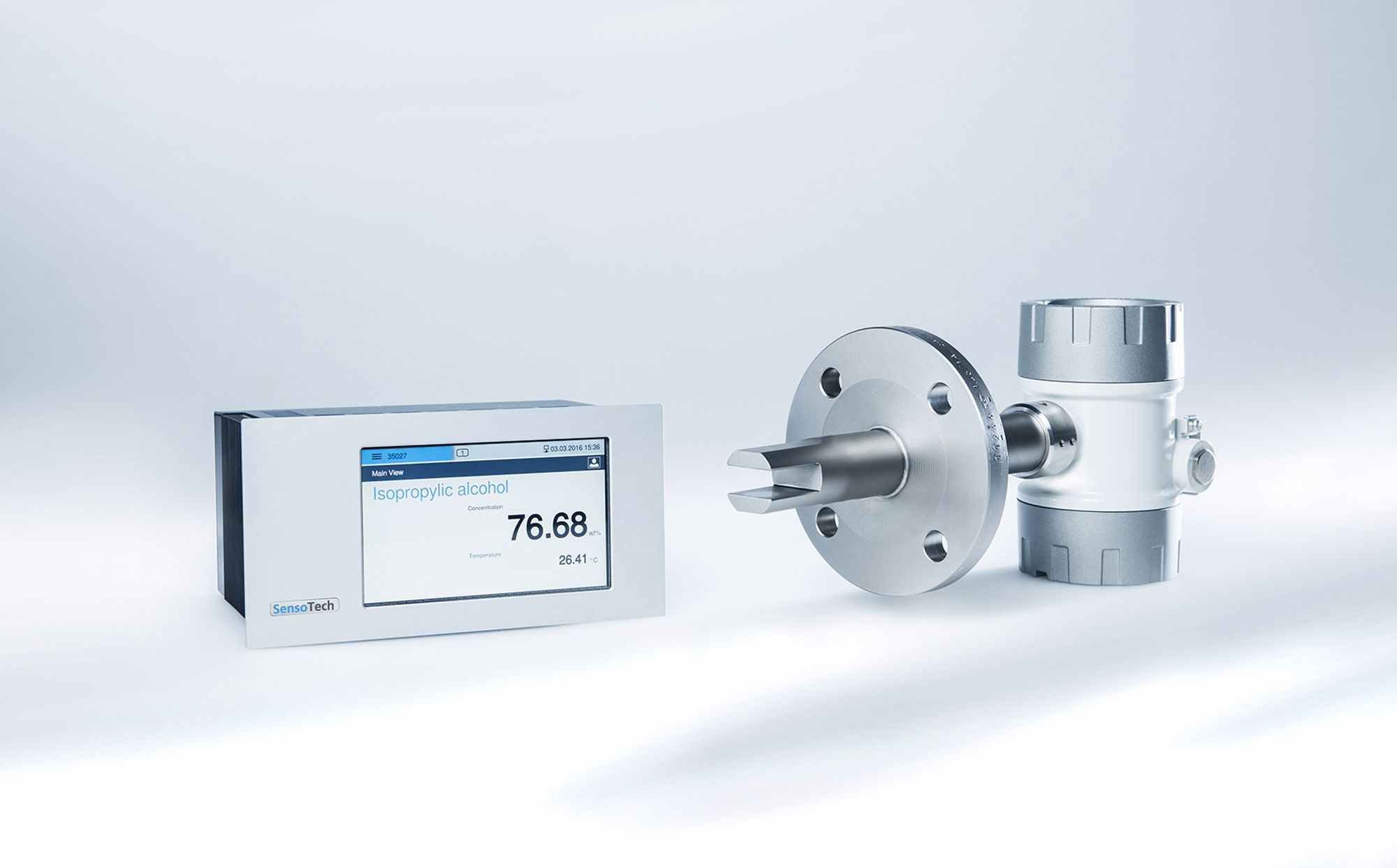

The LiquiSonic® Immersion sensors können direkt in der Rohrleitung an den gewünschten Stellen in der Anlage installiert werden. Der Einbauort muss so gewählt werden, dass der Sensor vollständig mit Prozessflüssigkeit in Contact ist. Ratsam ist daher ein Einbau in Steigleitungen oder alternativ von unten bei teilgefüllten Leitungen. Die kompakte Sensorkonstruktion ohne Dichtungen und ohne bewegliche Teile sichert lange Prozessstandzeiten des Systems. Der LiquiSonic® Controller 30 can be connected to up to 4 sensors. This makes it possible to monitor several measuring points simultaneously. With the help of the LiquiSonic® Lab Systems alternative spot measurements of samples in the laboratory can also be carried out in seconds.

Possible measuring range (depending on the respective liquid):

Concentration range: 0 to 100 m%

Temperature range: -20 to 140 °C

Customer benefits

The inline measuring system LiquiSonic® allows online monitoring of the current status of the purified medium using sound velocity. This ensures stable product quality. An elaborate

sampling and laboratory analysis is not required. The robust sensor design without moving parts and without seals guarantees reliable input analysis and monitoring in the long term. If required, the sensor parts in contact with the media are made of special materials, such as Hastelloy C2000. The sensors are available certified according to ATEX or FM.

Advantages for the user at a glance:

- Monitor product quality directly in the process

- suitable for explosive areas

- Optimization of processing cycles

- Regular laboratory tests become unnecessary

- Minimize error potential and risk for employees

Organic or aqueous solvents are used in many branches of the chemical industry. After use, they can either be disposed of at high cost or purified in distillation plants and then reused.