Inline green liquor monitoring

In paper and pulp manufacturing, both the acidic sulfite and the alkaline sulfate processes are used for breaking down wood. The wood fibers are separated from the natural material and other components, such as lignin. For ecological and economic reasons, the chemicals used must be recycled.

The aim is to regenerate caustic soda (NaOH) and sodium sulfide (Na2S) and the generation of energy, heat, and steam, while minimizing environmental damage.

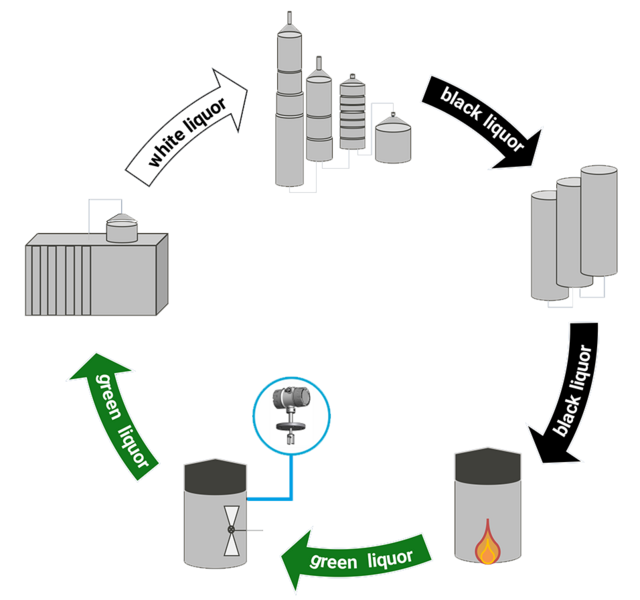

The lignin-containing black liquor produced during the breakdown process is concentrated and burned. In addition to energy and steam generation, a melt forms at the bottom of the boiler, which is regenerated in several recycling stages. The green liquor resulting from water and melt is converted into NaOH-containing white liquor by adding lime in the causticizing process, which is used again to break down lignin.

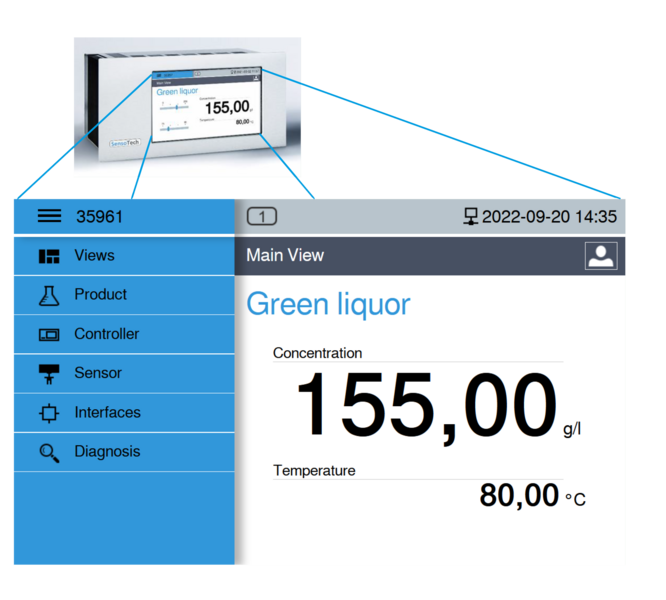

Through the LiquiSonic® measurement technology the green liquor treatment can be monitored inline at various points and the concentration for the subsequent causticizing can be determined.

Applications in the paper and pulp industry place high demands on all system components. Our application specialists design the sensors for the expected conditions. The robust measurement method, which operates without moving parts and seals, impresses with unparalleled runtimes. The sonic velocity sensors withstand temperatures up to 130°C, depending on the design. To ensure long runtimes, highly resistant materials and coatings are used.

Through the online analysis of green liquor concentrations using LiquiSonic® measurement technology lime can be specifically dosed. Furthermore, the individual process stages, such as the dilution of the melt to green liquor and its storage and clarification, can be permanently monitored and automatically controlled. Time delays caused by sampling and laboratory analyses are eliminated. This efficient process control results in quality improvement.

Measurement without LiquiSonic®

The measurement of green liquor is not an easy task due to the harsh environment and challenging measurement conditions. The plants have high temperatures up to 100°C, working with aggressive and corrosive liquids. Additionally, the media to be measured have high viscosity and adhesion tendency. A high proportion of solid particles and impurities, as well as suspended solids prone to crystallization, hinder adequate measurement.

Without continuous concentration measurement by LiquiSonic® only snapshots of concentration values are available. Manual sampling favors human errors. Additionally, the time delay between sampling and the availability of results leads to a process that cannot be adequately controlled. This often results in quality defects.

Measurement with LiquiSonic®

With LiquiSonic®, the solution by SensoTech, there is an increase in product quality because the relevant key figures in the green liquor process are always precisely known. Measurements are not taken at specific points, as with sampling, but every second throughout the entire process. Thus, there is no time delay between measurement and result, allowing for quick reactions to deviations, e.g., in the form of additional dosing.

In addition to saving time, inline measurement has another advantage: the influence of human errors is minimized, as the measurement values can be integrated into the process control system. The automated dosing of lime is more precise, making the process more efficient. This reduces lime consumption, leading to cost reduction. Frequent sampling and waiting for concentration measurement results are a thing of the past.

Furthermore, the LiquiSonic® sensor is not affected by deposited particles or impurities. Particularly robust are the LiquiSonic® Sensors due to the special polymer coating that makes working with aggressive and corrosive media possible. After installation and adaptation of the measuring system to the process, no cleaning, maintenance, or calibration is required!

Application

The starting material in lye recycling is black liquor in the recovery boiler. The melt formed during combustion sediments and must be diluted with water or thin white liquor. The resulting green liquor is Na2S and Na2CO3-containing, hot and is often stored in a separate tank. It is then clarified and stored in a green liquor collection tank. The prepared green liquor is converted to NaOH with quicklime in the causticizing plant.

Through the second-fast analysis of the LiquiSonic® Sensors individual process stages, such as the dilution of the melt to green liquor and its storage and clarification, can be permanently monitored and controlled. This efficient process control serves both to increase quality and to economically regulate the addition of lime.

Installation of the LiquiSonic® Measuring technology in the green liquor process

The LiquiSonic® Pipe sensors are installed directly into the green liquor transporting pipelines. The PFA coating ensures long-term measurement accuracy despite alkaline, hot process liquids and deposition tendency. The LiquiSonic® Controller 30 can be connected to up to 4 sensors to monitor the green liquor simultaneously at multiple measuring points:

- after the dissolving tank

- before clarification

- after clarification or before causticizing

Typical measuring ranges:

Concentration: 0 - 30 wt% or 950 - 1200g/l

Temperature: 5 - 95 °C

Customer benefits

The LiquiSonic® Measuring system offers numerous advantages in paper and pulp production, especially in green liquor treatment:

- stable and maintenance-free operation despite the deposition tendency of green liquor

- Reduction of maintenance and cleaning costs, no cleaning accessories needed

- precise concentration determinations in green liquor, as well as black and white liquor

- traceable monitoring with data recording

- increase in operational safety