Concentration and density measurement of H2SO4 in copper mining

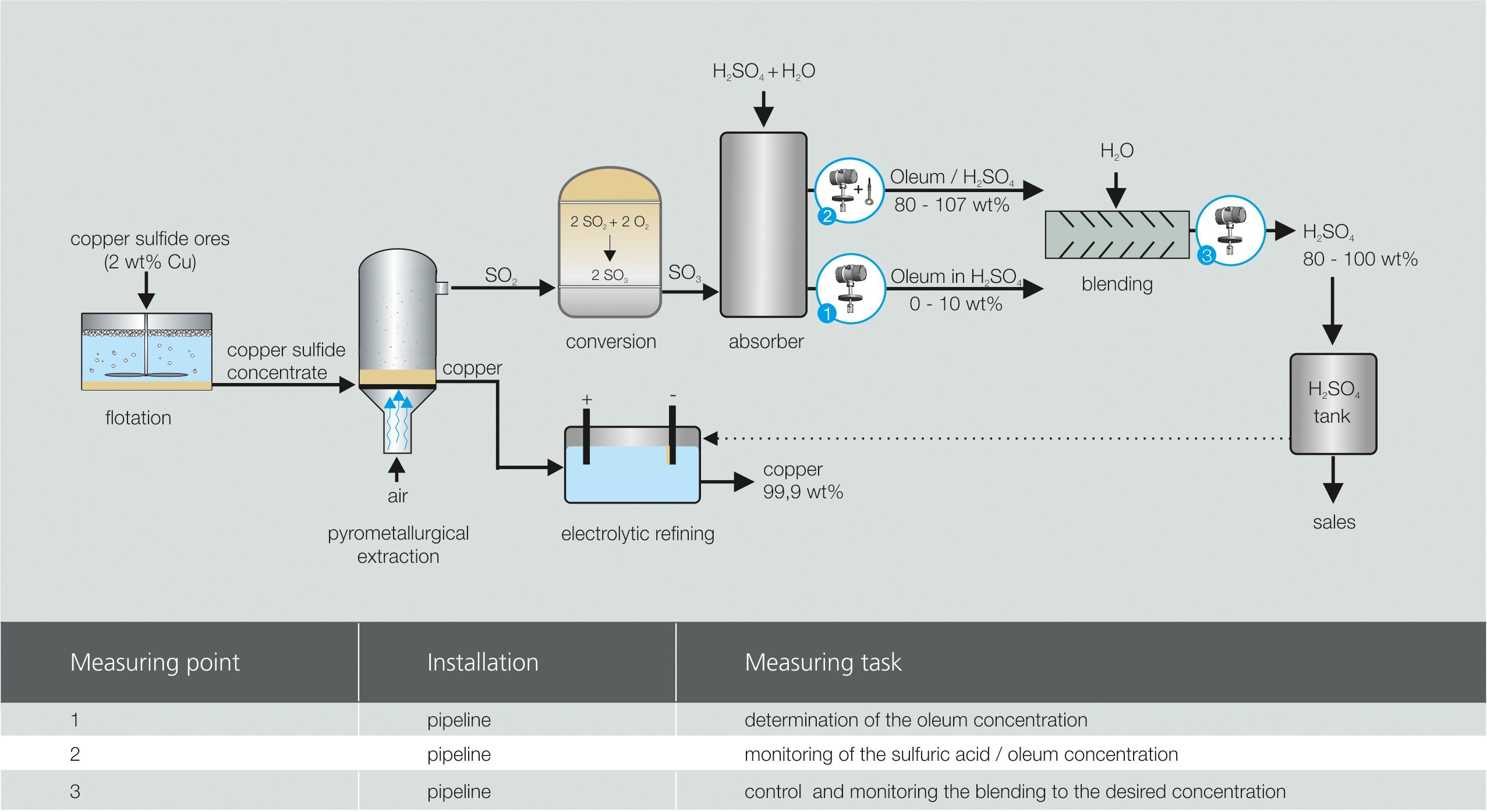

The processing of copper sulfide ores is done by flotation. The ground copper sulfide ores are enriched with water and a foaming agent to skim off quartz or silicates. The resulting copper concentrate has a copper content of 20-40 wt%.

In pyrometallurgical extraction, SO2 is produced, which is technically oxidized with atmospheric oxygen to sulfur trioxide (SO3) (contact process). A copper content of approx. 96 – 99 wt% remains. For a purity of 99.99 wt%, electrolytic refining follows. This is necessary because the thermal and electrical conductivity of the copper is greatly affected by impurities.

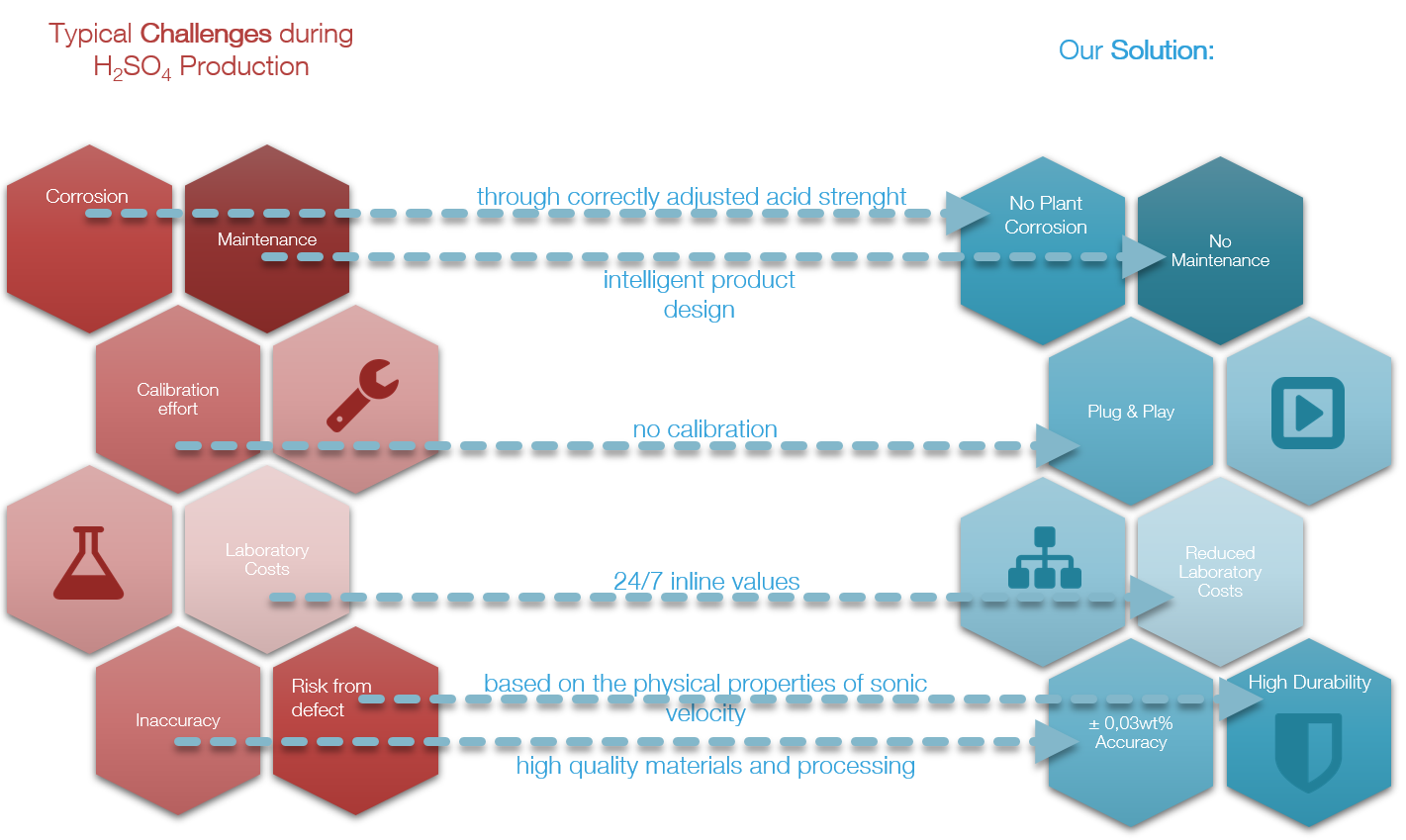

Difficulty in density and concentration measurement of sulfuric acid

In the process of sulfuric acid production, process engineers often face a challenge:

Numerous measurement methods intended to measure the concentration or density of sulfuric acid function inadequately at a concentration of 85 wt% - 99 wt%. Problems particularly arise when the underlying physical value of the concentration or density measuring device does not change with a change in concentration.

Based on the diagram, it is clear, for example, that conductivity sensors provide poor measurement results in a concentration range of sulfuric acid from 80 wt% - 97 wt% because the conductivity of the liquid hardly changes in this concentration range. For this reason, conductivity sensors have extremely low measurement accuracy when sulfuric acid is to be analyzed in this measurement range.

Similarly, with density measuring devices, where the density of the liquid itself is to be evaluated, it is shown that particularly in measurement ranges above 90 wt%, the density of the liquid hardly changes. Therefore, numerous simple density measuring devices have significant problems when they are to be used to measure the concentration of sulfuric acid in this measurement range.

LiquiSonic® sound velocity measurement in comparison

Measure concentration and density of sulfuric acid precisely using sound velocity

Unlike conductivity sensors or density sensors, ultrasonic measuring devices are able to measure the concentration of sulfuric acid extremely precisely. With a change in the concentration of sulfuric acid, the sound velocity also changes very strongly. Therefore, concentration measuring devices whose sensors evaluate the sound velocity provide much more accurate measurement results than conductivity measuring devices or density measuring devices.

Application

In pyrometallurgical extraction, the copper concentrate is slagged by adding SiO2 in a reverberatory furnace at 1200 to 1400 °C. This results in a melt of copper and iron sulfide, which is separated as so-called copper matte from the slag phase. The liquid copper matte is poured into a converter and the iron sulfide is oxidized with air supply to sulfur dioxide SO2 oxidized. The resulting SO2 is oxidized to sulfur trioxide (SO3) (contact process) and the SO3 is introduced into the absorber in 96% sulfuric acid, whereby highly concentrated H2SO4 or oleum is formed. In blending, the H2SO4 is then diluted to the targeted concentration.

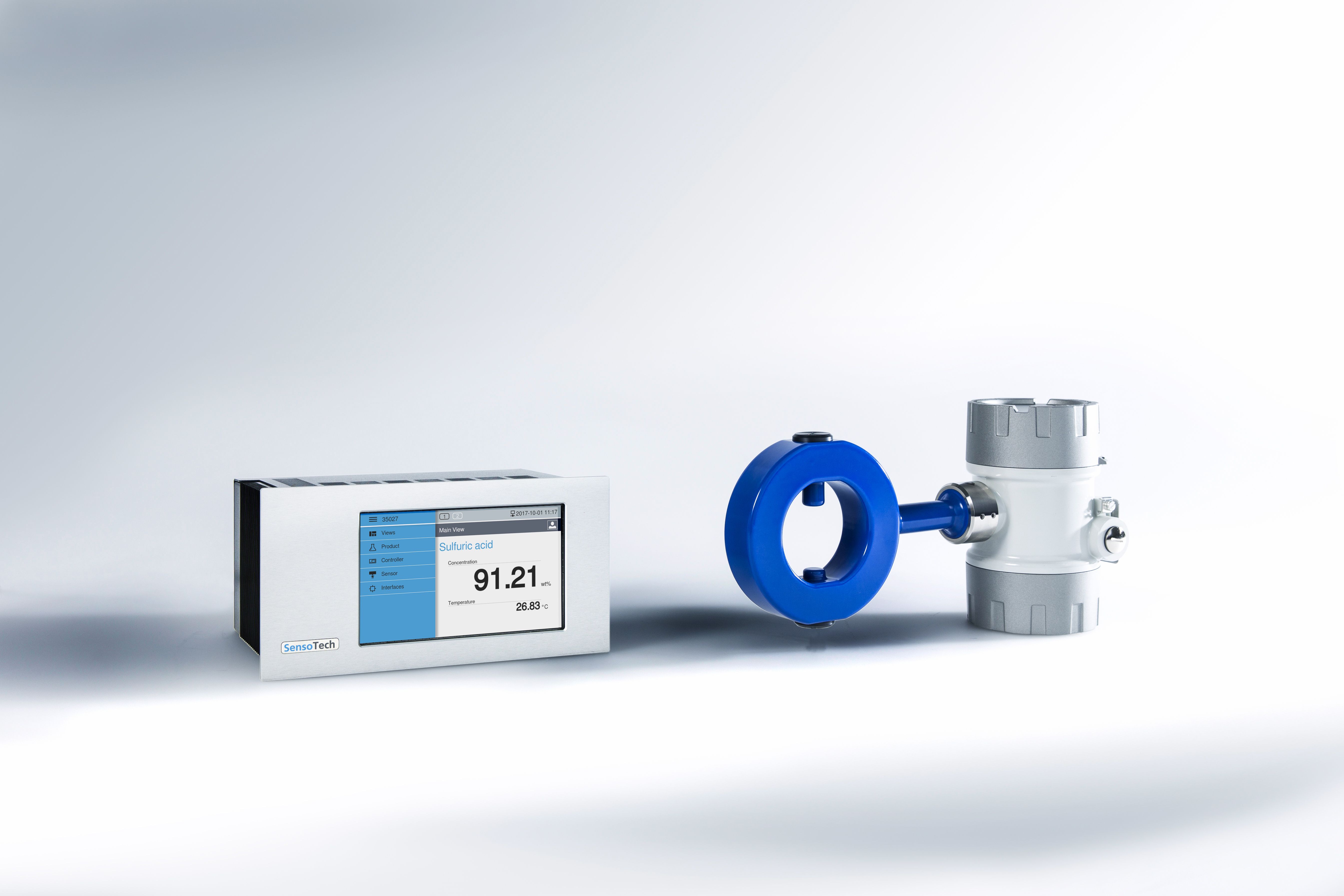

The individual process stages can be continuously monitored inline and optimally adjusted by Liqui-Sonic® measurement technology. Due to the high dependency of sound velocity, an accuracy of +/- 0.05 m% is achieved with sulfuric acid.

The LiquiSonic® immersion sensors can be easily installed in the pipelines after absorption or sulfuric acid production or blending. The LiquiSonic® Controller 30 can be connected with up to 4 sensors. This makes it possible to monitor several measuring points simultaneously.

Typical measurement ranges:

Concentration range H2SO4: 80 - 100 m%

Temperature range: 20 - 90 °C

Concentration range oleum: 0 - 30 m%

Temperature range: 10 - 60 °C

Customer benefits

LiquiSonic® ensures precise analysis and monitoring of H2SO4 or oleum concentration with permanent data recording. The robust sensor construction and the choice of special materials, such as Hastelloy C2000, ensure long process uptime of the system.

LiquiSonic® reduces time-consuming laboratory measurements:

- Time savings: 1 h per day

Compared to conductivity and density measurement, it generates LiquiSonic® a clear signal in the concentration range of 80 to 100 m% and thus always provides reliable process information.

The extraction of copper is done by mining copper sulfide ores, which have a copper content of about 2%. The raw metal extraction involves various processing steps.