Monitoring of oil concentration in the refrigerant circuit

Decades of experience show that measurements in research, especially in the refrigerant circuit, are complex and complicated. Sampling is often difficult or not possible at all. Therefore, the ratio between oil and refrigerant must be estimated by indirect methods.

The goal is to find out how efficiently a cooling system operates depending on the oil concentration. The information obtained from the measurements provides insights into how the processes in the compressor proceed and when it is no longer operational.

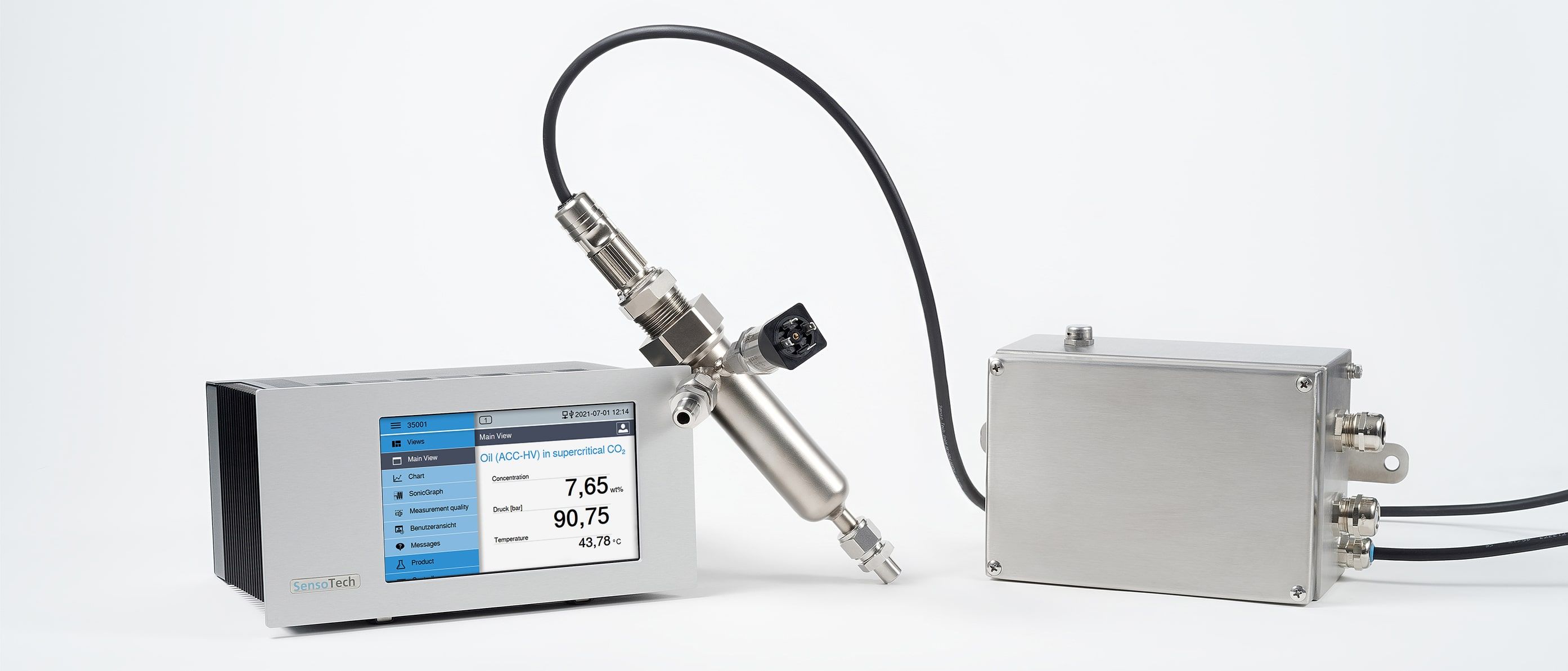

To perform the measurements as precisely as possible, SensoTech has developed the inline solution LiquiSonic® OCR which brings unbeatable advantages.

What if the ratio between oil and refrigerant is known at all times and with high precision?

What if no elaborate samples had to be taken to determine the oil/refrigerant ratio?

Through LiquiSonic® OCR comprehensive information about the refrigerant process is continuously available. The permanent knowledge of the concentration ensures optimal process control, while the rapid approach to the optimal oil/refrigerant ratio reduces the adjustment time.

The optimal ratio of refrigerant and oil with LiquiSonic® OCR

SensoTech makes it possible to have precise knowledge of the concentration of compressor oil in refrigerant at all times. Accurate inline measurements eliminate the need for elaborate and error-prone sampling. Measurement values are available at all times and are updated every second.

Highest precision in monitoring oil in the refrigerant circuit

SensoTech places the highest value on precise measurements when monitoring oil concentration. The determination of oil concentration is based on pressure, temperature, and sound velocity measurements in the liquid refrigerant. This highly accurate measurement principle allows precise adjustment of the desired oil circulation speed.

Continuous determination of oil concentration instead of spot measurements

The great advantage of online oil condition monitoring is the permanent availability of the measurements. Due to the second-by-second update of the data, the operator always has precise knowledge of the measured oil concentration. Time-consuming adjustments of the oil concentration in the circuit are thus a thing of the past.

Monitoring a variety of refrigerants with just one refrigerant measuring device

SensoTech impresses with sustainable and comprehensive process solutions. A total of up to 32 product data sets (calculation models) can be stored in the controller. This makes it easy to cover a wide range of refrigerants with the LiquiSonic® measurement technology to monitor. Due to decades of experience and manufacturing of measuring devices, there is almost no refrigerant left that has not yet been measured by SensoTech.

Selection of measured refrigerants

- R134a

- R407c

- R410A

- R744

- R1234yf

- R1234ze

- R290 (Propane)

- R1233zd (E)

- R407A

- R404A

- R454-B

- R454-C

- R717 (Ammonia)

Selection of measured compressor oils

- D11

- ND12

- PAG

- ACC-HV

- POE 68

Holistic support for the analysis of oil in the refrigerant circuit

- Clarification of the framework conditions

First, the user is consulted to determine which medium is to be measured. The SensoTech engineers check whether the combination of refrigerant and oil is already present in the existing database. If this is not the case, the feasibility of the measurement is determined in the in-house laboratory. - Clarification of the specification for the measurement of oil in refrigerant

Once the measurement task is clear, specifics are clarified. Among other things, whether special materials, installation variants, or special accessories are required for monitoring in the refrigerant circuit. The system developed for this application LiquiSonic® OCR system already has, for example, a special measuring head and an adapter vessel. This equipment enables seamless integration into the refrigerant circuit. - Installation qualification on site at the refrigerant circuit

If desired, SensoTech supports the entire process. Our application engineers check the correct installation of the measurement system and verify that the initial measurements are running correctly. - Regular training and education

For various applications, SensoTech offers additional webinars and training sessions. This allows the operator to familiarize themselves with the measurement system in advance or discover new functions afterwards. - Provision of new datasets for oil in refrigerants

The LiquiSonic® measurement system is not limited to a specific refrigerant or oil. As part of investigations, different refrigerants, such as refrigerant R32 and R134a, are analyzed in SensoTech's in-house laboratory. The use of another refrigerant later on is not a problem. For this, SensoTech simply calculates a new dataset, loads it onto the controller, and the oil content in the new refrigerant can be determined. - Consultation on follow-up projects

For questions regarding projects or further applications, the competent team at SensoTech is available for consultation.

Application examples of already measured refrigerants

There are countless refrigerants in use worldwide. As a globally operating company, SensoTech has already realized numerous projects with partners.

Oil circulation rate in R410A

- Mainly used in refrigeration and air conditioning systems as well as in heat pumps in buildings

- Very precise inline determination of oil concentration

- Replacement refrigerant for banned R22 systems

Refrigerant analysis for R1234yf

- 357 times more climate-friendly than other used refrigerants

- Used as a replacement for R134a in new cars

- More efficient operation at higher temperatures

- Used in automotive air conditioning systems

Oil in refrigerant R134a

- Banned in new cars within the EU, therefore often used outside the EU

- Worldwide use in automotive air conditioning systems

- R134a is considered a standard reference worldwide

FAQ on determining the concentration of refrigerant oil

For questions regarding the measurement of oil concentration in the refrigerant circuit or the measurement system LiquiSonic® OCR the competent team of SensoTech is available.

Frequently Asked Questions:

- Why is sampling for determining the concentration of the refrigerant-oil mixture problematic?

Sampling to determine the concentration is inaccurate and cumbersome because the closed system is interfered with. In general, refrigerants evaporate as soon as they come into contact with air. The samples amount to about one liter. The analysis is carried out in the laboratory. The concentration of oil in refrigerant to be determined is only available after some time and is only a snapshot. The missing sample amount ensures that the determined measured value does not reflect the current concentration. The systemmust first settle again. Real-time inline monitoring is therefore preferable to sampling. - What is the purpose of the oil in a refrigeration system?

The oil in the refrigeration system lubricates the compressor and ensures that it operates smoothly and does not get damaged. The perfect mixture ratio of oil and refrigerant must be maintained. The rule is: as little oil as possible, but as much as necessary. Too much oil can, among other things, reduce the cooling performance. - What happens if there is too much oil in the AC system?

If there is too much oil in the AC system, it results in a reduction of cooling performance. This reduction ensures that the AC system only functions to a limited extent, thus requiring more time to reach the desired cooling or the desired temperature may not be achieved. - What type of oil is used in the refrigerant?

There are a variety of combinations of oil and refrigerant used in different compressors. The exact type of oil used depends entirely on the compressor manufacturer, as the respective compressors are only suitable for certain oils. - Can the refrigerant in the air conditioning system be replaced with another?

While measurements can be made in any known refrigerant, not every air conditioning system can use every refrigerant. If a different refrigerant than the previous one is used, it can attack and damage the compressor seals.