Phase separation

Benefits for the user are:

- Fast detection of phase differences (response times of less than 1 s)

- Replacement of manual, visual, or indirect detection methods (e.g., time control)

- Improvement of product yield

- Saving of energy and material costs

- Optimal plant control through online information about the process state

- Increased plant safety through continuous monitoring

The use of the latest digital signal processing technologies guarantees extremely accurate and interference-free measurement of the absolute sound velocity and concentration of various media in phase separation. Additionally, integrated temperature sensors, sophisticated sensor design, and expertise developed in countless measurement series and many applications ensure high system reliability with long service life.

The advantages of the measurement method are:

- Absolute sound velocity as a clear and traceable physical quantity

- Independent of color, conductivity, and transparency of the process liquid

- Installation directly in pipelines and containers

- Robust sensor design in completely metallic construction without seals or moving parts

- Maintenance-free

- Corrosion resistance through the use of special materials

- Use at temperatures up to 200 °C

- High, drift-free measurement accuracy even with a high gas bubble content

- Connection of up to four sensors per controller

- Forwarding of measurement results via fieldbus (Profibus DP, Modbus), analog outputs, serial interface or Ethernet

1. Process

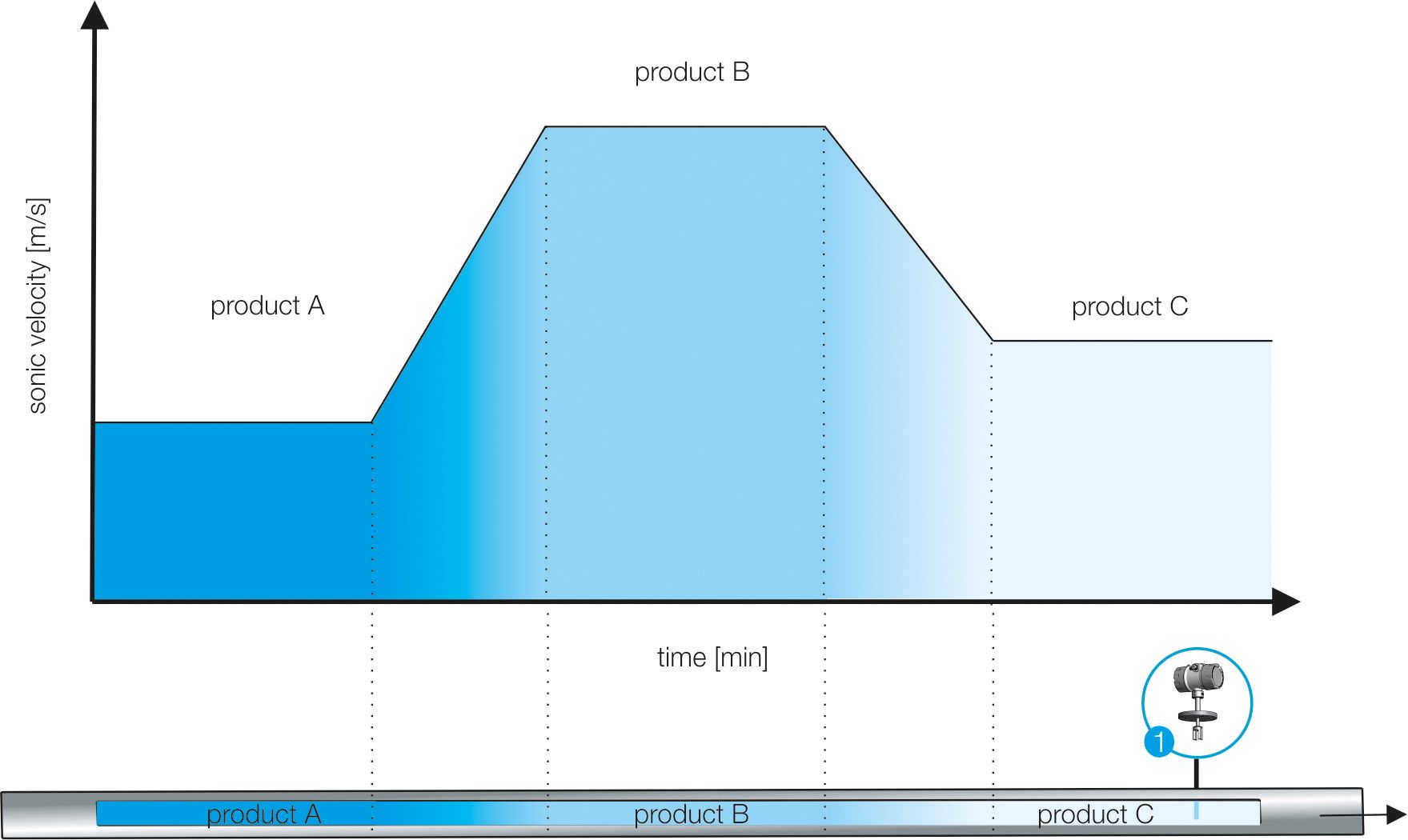

1.1 Phase separation in the pipeline

The exact detection of different phases in a pipeline is necessary in various industrial sectors. Often, the different products are conveyed through the same line, but each is delivered to a different location.

In applications where, for example, product A is displaced by product B, the intermediate phase must be separated. In breweries, different types of beer are filled one after the other, but the pre- and post-runs are separated and fed back into the brewing process.

Safety aspects also play a role in applications with high risk potential. Especially the monitoring of phase separation in multi-substance pipelines of the chemical industry not only provides information about product quality (incoming goods), but also prevents incorrect filling of storage tanks and thus serious accidents.

In petrochemicals, different fuels are transported over very large distances in just one pipeline. Here, both the rapid identification of different products and their quality monitoring are the focus.

1.2 Phase separation in the batch process

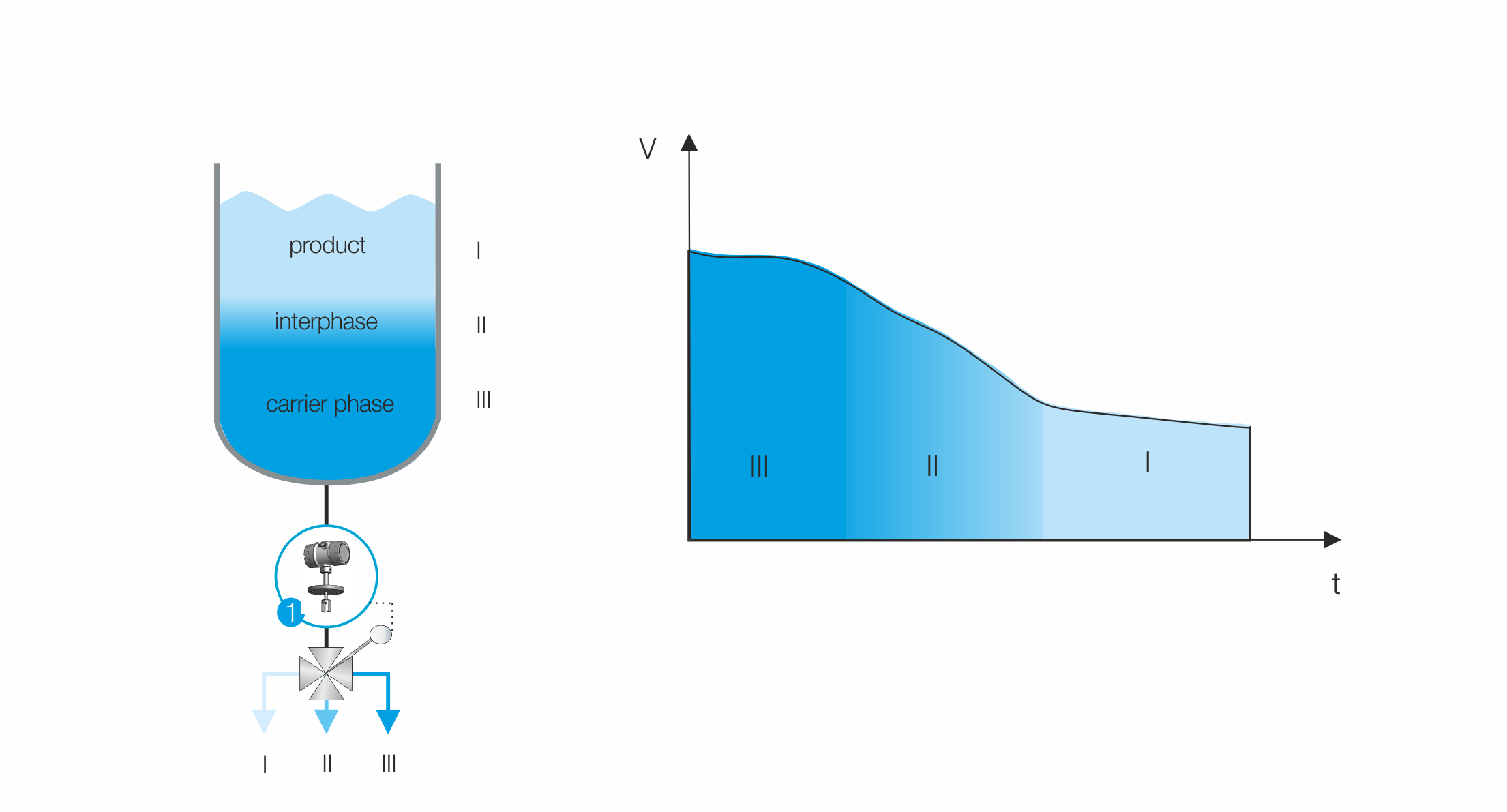

The separation of two phases can be carried out in batch processes. Here, the liquids (e.g. water and oil) separate from each other due to their physical and chemical properties.

Application example 1: Organics

During the manufacturing process of cosmetics, phase separation occurs, where a saline phase containing a lot of water is separated from a precursor. This water-rich, lower phase is discharged through the treatment plant, where the water is treated. The produced precursor, the upper phase, is only biodegradable to a limited extent. Therefore, it is of utmost importance to prevent this water-polluting material from entering the wastewater. To avoid burdening the water in the treatment plants, theimmediate and reliable identification of the precursor phase is of the highest priority to prevent it from being fed into the wastewater system by a rapid shutdown.

Optical measurement methods are ruled out at this point because different colorations can occur during phase separation. Furthermore, during phase separation, a sludge layer can form, which is known to be critical for measurement through optical boundary effects due to contamination effects.

Application example 2: Biodiesel / Glycerin

During the production of biodiesel, glycerin is produced as a by-product. The mixture of both substances is conveyed into large settling tanks and then has several hours to separate. LiquiSonic® sensors are usually installed at the outlet of the tank. By detecting the respective phase, the valve is controlled, and the biodiesel and glycerin are fed to their respective further processing. The intermediate phase returns to the separation process.

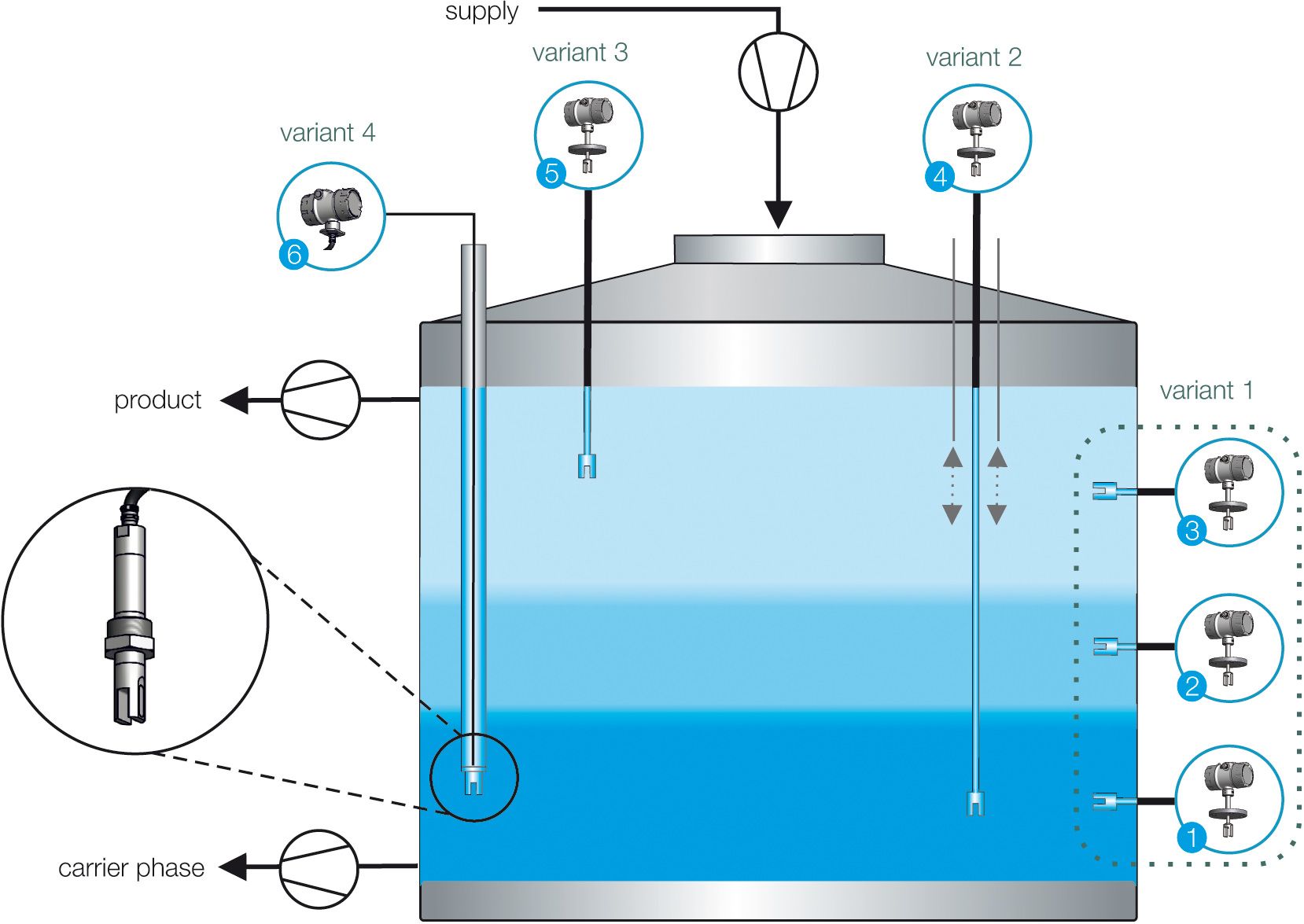

1.3 Phase separation in the continuous process

LiquiSonic® installation variants for phase separation in the continuous process

In a continuous process, the separation of a process stream is controlled by one or more sensors. In this case, only the sound velocity value characteristic for the respective phase is monitored and kept constant.

Often, the product concentration of the carrier phase fluctuates in the inlet. This quickly shifts the height of the phase boundary. As a result, the carrier phase could be withdrawn with the product, which greatly affects the purity. Technically, the separation of liquids is carried out via a pump in each of the two outlet lines. In this way, for example, the continuous separation of a reaction mixture can be controlled.

The advantages of LiquiSonic® measurement technology are not only in the extremely fast response time of less than 1 second, but also in the connection of up to four sensors to just one LiquiSonic® controller. This processes all measurement values and forwards the data to the higher-level control system.

Depending on the type of container and requirements, different installation variants are possible, which are shown in the graphic below.

Installation variant 1

The sensors are most frequently installed on the side of the container. The necessity of the middle sensor (measurement point 2) depends on the application and the characteristics of the intermediate phase.

Installation variant 2

When using only one sensor with a length of up to 4 m, the phase profile of the entire container can be determined. By mounting the sensor on a movable carriage, for example, and in combination with a distance meter, the phase boundaries can be determined precisely at their current height.

Installation variants 3 and 4

In containers where no side connections are present or can be subsequently implemented, e.g., heated double jacket, the sensors are positioned directly or via immersion tubes at the correct location. When using immersion tubes, the sensor electronics are located remotely at a distance of up to 15 m outside the container.

2. LiquiSonic® System

2.1 LiquiSonic® 30

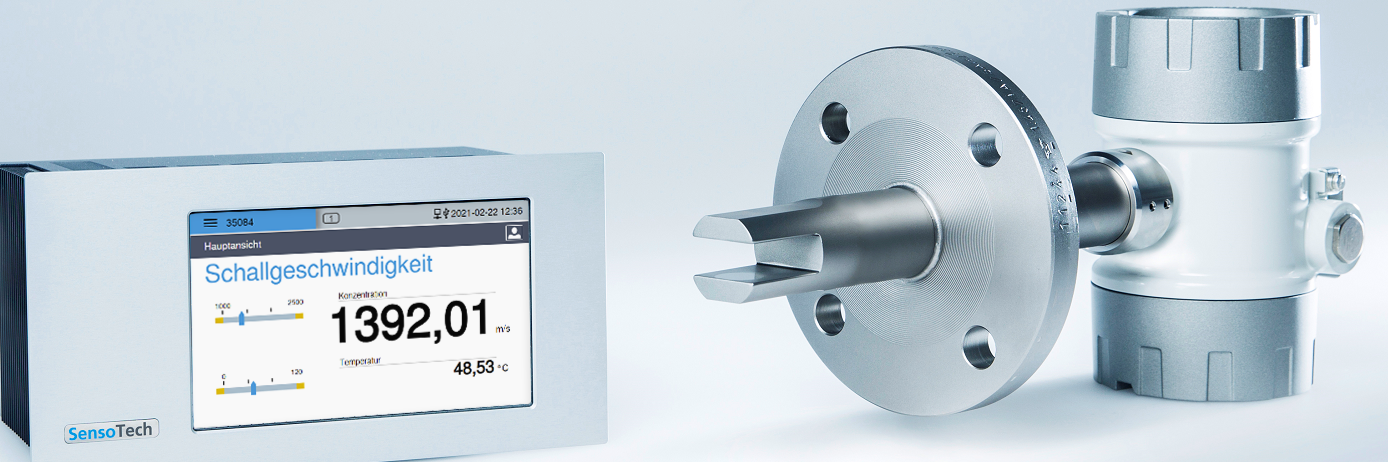

The LiquiSonic® System consists of one or more sensors and a controller. The ultrasonic sensor includes the ultrasonic measurement path as well as high-precision temperature detection. Each sensor operates autonomously and can be used in different applications. The liquid-contacting parts of the sensor are made of stainless steel DIN 1.4571 as standard.

The robust and fully encapsulated design requires no seals or 'windows' for application and is therefore completely maintenance-free. Various additional functions integrated into the sensor, such as the flow monitor and wet/dry monitoring, significantly increase customer benefits. The LiquiSonic® high-performance technology ensures stable measurement results, even with increased gas bubble content and strong signal attenuation by the process fluid.

The special sensor electronics are housed in a closed die-cast housing with IP65 protection. In confined spaces, sensors with remote electronics can be installed. The Controller 30 manages the measurement data and takes over the visualization. Operation is via the high-resolution touch display. Through secure network integration including a web server, the controller can alternatively be operated via a browser with a PC or tablet.

The display value can be adjusted to internal reference values through the adjustment function. The process data is updated every 250 milliseconds. If the measured values are outside the limit range, this is displayed and a signal is immediately triggered.

The measurement data can be transmitted to controllers, process control systems, or PCs via several freely scalable analog or relay outputs as well as various fieldbus interfaces. The measurement data is stored in the extensive data logbook. There are 2 GB available for process information and 32 (optionally 99) product data records for various process liquids. For processing on the PC, these can be read out via network or USB interface. Furthermore, process protocols can be easily created for documentation purposes.Additionally, an event logbook is integrated into the controller 30. It documents events such as a manual product change, configuration changes, or warning and status messages.

2.2 Accessories

2.2.1 Controller and Field Housing

The controller is designed for installation in control panels. Alternatively, a 19" 3U housing is available. To use the controller in the field, plastic or stainless steel field housings are available.

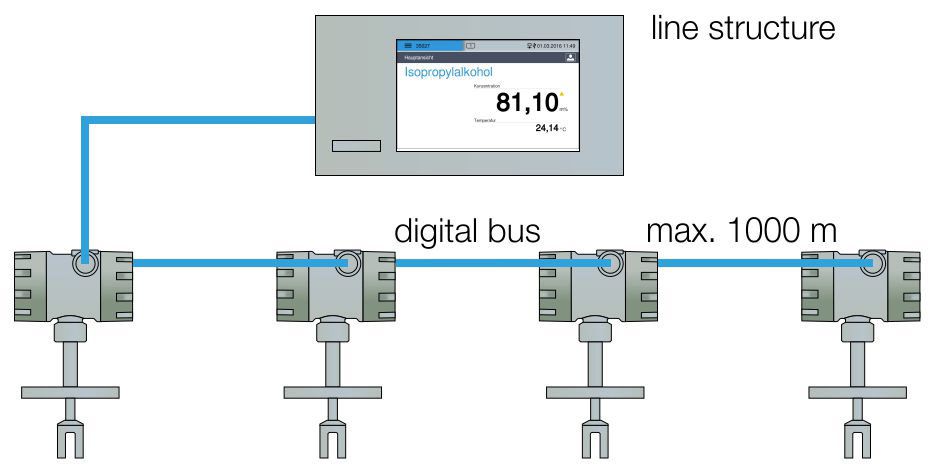

2.2.2 Fieldbus

The fieldbus option provides the ability to integrate the controller into a process control system or to automate the process sequence using control (PLC). In addition to transmitting measurements such as concentration or temperature, parameters and control data (e.g., product switching) can also be exchanged.

The controller supports various fieldbus systems and follows the standards recommended by the respective standardization organizations. Common variants include Modbus and Profibus DP.

3. Quality and Service

Enthusiasm for technological progress is our driving force to help shape the market of tomorrow. You, our customers, are at the center. We are committed to delivering top performance to you. In close collaboration with you, we follow the path of innovation – by developing the right solution for your demanding measurement task or performing individual system adjustments. The increasing complexity of application-specific requirements makes a comprehensive understanding of connections andinteractions essential.

Creative research is another key pillar of our company. Our research and development team specialists contribute valuable work to optimize product features, such as testing innovative sensor designs and materials or the thoughtful functionality of electronics, hardware, and software components. Our SensoTech quality management accepts only top performance in production. Since 1995, we have been certified according to ISO 9001. All device components undergo variousproduction stages with diverse testing procedures; the systems are subjected to a burn-in procedure in our facility. Our maxim: highest functionality, durability, and safety.

All this is only possible through the dedication and pronounced quality awareness of our employees. We owe our success to their excellent expertise and motivation. Together, with passion and conviction, we work with excellence that is second to none.

We maintain relationships with our customers. They are based on partnership and developed trust. Since our devices are maintenance-free, we can focus entirely on your concerns in terms of service and actively support you through professional advice, convenient in-house installation, and customer training. In the conceptual phase, we analyze your situational conditions directly on-site and, if necessary, conduct test measurements. Our measuring devices are capable of achieving the highest performance even under unfavorable conditions.Accuracy and reliability. Even after installation: We are there for you, our response times are short – thanks to remote access options specifically tailored to you.

As part of our international cooperations, we form a globally networked team for our customers that ensures optimal consulting and service across borders. Therefore, we value effective knowledge and qualification management. Our numerous international representatives in all major geographic markets of the world can draw on the expert knowledge within the company and continuously update their competence in application- and practice-oriented training programs. The proximity tocustomers around the globe: besides comprehensive industry experience, a key factor for our successful presence worldwide.

Innovative sensor technology

SensoTech is the specialist for the analysis and optimization of process engineering processes in liquids. Since its founding in 1990, we have developed into the leading company for measuring devices for inline determination of concentrations in liquids. Our analysis systems set the trend worldwide.

Innovative engineering made in Germany, whose principle is the measurement of the absolute sound velocity in the ongoing process. A method that we have perfected into a highly precise and exceptionally user-friendly sensor technology.

Typical applications besides concentration and density measurement are phase detection or tracking of complex reactions such as polymerization and crystallization. Our LiquiSonic® measurement and analysis systems ensure optimal product quality, highest plant safety, or reduce costs through efficient resource management in various industries, such as the chemical and pharmaceutical industry, steel industry, food technology, mechanical and plant engineering, automotive technology, and others.

We want you to fully exploit the potential of your production facilities at all times. SensoTech systems provide highly accurate measurement results even under difficult process conditions, precise and reproducible. And this inline and without safety-critical sampling, immediately available for your automation system. All system parameters can also be adjusted with powerful configuration tools so that you can react immediately and easily to changes.

We offer excellent, mature technology to improve your manufacturing processes and are a partner for demanding, often unexpected solution approaches in your industry, for your applications – no matter how specific. When it comes to liquids, we set the standards.

LiquiSonic® is an inline analysis system that determines the concentration or density of liquids or media directly in the process without delay. The device is based on the highly precise measurement of the absolute sound velocity and process temperature, thus allowing the detection of phase differences.